Powdered Activated Carbon for Waste Incineration Plant Flue Gas Treatment

- Over 20 years of industry experience in powdered activated carbon manufacturing.

- Annual output 18000 tons. 16pcs Production Patents.

- Low ash content, clean.

- Low moisture content, not easy to stick together.

- High Methylene blue

You will get a quote in 24 hours

With the acceleration of urbanization and the surge in garbage generation, traditional landfill disposal methods can no longer meet the needs of environmental protection and land resources. As an important facility for modern waste treatment, garbage incineration plants play a key role in reducing garbage volume and achieving resource recovery.

What is the flue gas in waste incineration? The flue gas produced during waste incineration contains a large amount of harmful substances, such as dioxins, furans, heavy metals and acid gases, which pose a serious threat to the environment and human health.

In order to effectively control these pollutants, activated carbon, as a highly efficient adsorbent, is widely used in the flue gas purification system of waste incineration plants. Its unique porous structure and strong adsorption capacity make it one of the key technologies for removing toxic and harmful components in flue gas.

What is Activated Carbon Mostly Used For?

Dioxins and Furans--Organic Pollutants

Dioxins and furans are collectively referred to as “dioxin-like compounds”, which are highly toxic pollutants generated during food waste incineration. They are characterized by bioaccumulation and persistence. Generally, they are adsorbed through the dry or semi-dry injection of powdered activated carbon.

Heavy Metals Removal (mercury and lead)

Mercury vapor (Hg⁰) is released when garbage is burned. Once it enters the atmosphere, it easily forms methylmercury, which is extremely harmful to the human body. How does activated charcoal injected into the flue gas remove mercury?

Powdered activated carbon injection mercury removal for waste incineration can oxidize mercury (Hg) to HgCl₂ through chemical adsorption, which is then adsorbed by the carbon pores. Impregnated activated carbon, such as phosphoric acid impregnated activated carbon, can be used to improve the removal efficiency of heavy metals.

Volatile Organic Compounds (VOCs) Removal

Paint, plastic, electronic waste incineration releases VOCs such as benzene, toluene, and xylene. Activated carbon can effectively absorb these harmful gases and reduce air pollution.

Acid Gas Control

Incineration of leather waste will produce hydrogen sulfide H2S, hydrogen chloride HCl and cyanide. Incineration of plastic and rubber waste will produce fluorides such as hydrogen fluoride HF.

Activated carbon for waste incineration can be used in combination with lime or sodium carbonate to absorb acidic gases such as hydrogen chloride HCl, sulfur dioxide SO₂, nitrogen oxides NOx, and hydrogen fluoride HF in flue gas, reducing the emission of corrosive pollutants.

Generally, dry or semi-dry methods are used to spray activated carbon in combination with alkaline absorbents to enhance the purification effect.

You will get a quote in 24 hours

You will get a quote in 24 hours

How to Use Activated Carbon for Waste Incineration?

After the flue gas leaves the incineration boiler, powdered activated carbon is sprayed into the flue before entering the dust collector to adsorb heavy metals and dioxins, ensuring that the emission concentration of heavy metals and dioxins meets national emission standards.

Activated carbon for waste incineration has a large specific surface area, so as long as the activated carbon and flue gas are mixed evenly and have a sufficient contact time, the required purification efficiency can be achieved.

After the activated carbon is sprayed into the flue, it begins to adsorb heavy metal pollutants such as dioxins and Hg in the flue, but it does not reach saturation. Then it enters the bag filter together with the flue gas and adsorbs on the surface of the filter bag, fully contacting with the flue gas passing through the surface of the filter bag, and finally achieving the purpose of removing heavy metals and dioxins in the flue gas.

Advantages of Activated Carbon for Flue Gas

- High adsorption capacity: can effectively remove pollutants such as dioxins, mercury and VOCs.

- Strong adaptability: can be used in combination with other waste gas treatment technologies (such as bag dust removal and wet scrubbing).

- Environmentally friendly and efficient: reduce the emission of atmospheric pollutants and comply with environmental regulations.

Best Activated Carbon for Waste Incineration Flue Gas

For waste incineration power plants, Heycarbons recommends using coal-based powdered activated carbon with an iodine value of 600-1000mg/g and a mesh size of 200, with a moisture content of <5% max, and an ash content of 8-20 %. If the moisture content is high, the activated carbon powder will not float and will easily stick together and explode.

In order to ensure that powdered activated carbon for waste incineration can be sprayed, the moisture content of activated carbon must not be higher than 10%. This requirement places high demands on the drying step in the production process of activated carbon for waste incineration. Each batch of activated carbon is tested for moisture content after drying and before packaging to ensure that the product meets strict standards and the adsorption capacity is not affected.

Activated carbon for waste incineration cost FOB is CNY2600-6000 per ton. If you want to know more information of activated carbon for waste incineration cost, please click the link below to contact heycarbons staff. Heycarbons will provide you with professional advice and high-quality activated carbon products for your business.

More information about powdered activated carbon:

Powdered Activated Carbon

You will get a quote in 24 hours

You will get a quote in 24 hours

Activated Carbon Adsorbs Flue Gas in Waste Incineration Plants Customer Case-A Domestic Waste to Energy Plant

Waste to Energy Plant Introduction

The power plant uses domestic waste as raw material and uses a grate furnace for incineration. The furnace uses 0.4% powdered carbon per ton of waste, and the temperature of the powdered activated carbon port is 170-180℃.

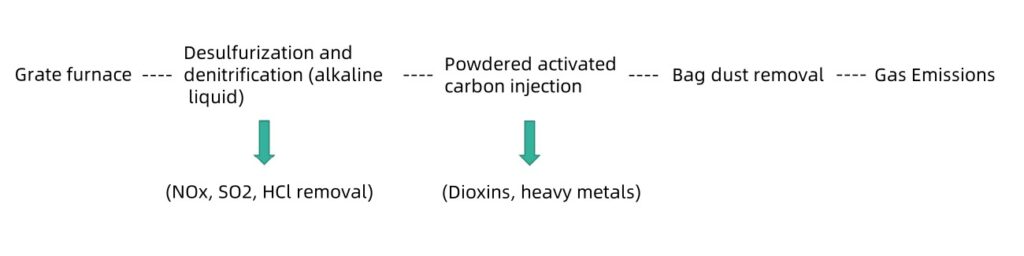

Waste Incineration Process

After the exhaust gas leaves the boiler, it is desulfurized and denitrated using alkaline liquid, mainly removing NOx, SO2, and HCl. Then powdered activated carbon is injected to remove dioxins and heavy metals. Finally, the reaction products and fly ash are collected through bag dust removal, and the gas that meets environmental quality standards is discharged.

In this process, the parameters of the Heycarbons activated carbon for waste incineration products used are as follows:

| Coal-based powdered activated carbon parameters in domestic waste to energy plant | ||||||||

|---|---|---|---|---|---|---|---|---|

| Ash | Moisture | 250 mesh passing rate | Specific surface area | Carbon tetrachloride CCl₄ adsorption rate | Iodine adsorption rate | Combustion temperature | Smoke temperature | Material consumption value |

| ≤10% | ≤5% | ≥95% | ≥800m2/g | 30-80% | 700-1000mg/g | 700℃ | 450℃ | 0.336t/d |

Activated Carbon Adsorbs Flue Gas in Waste Incineration Plants Customer Case-A Waste to Energy Plant in Taiwan

Waste to Energy Plant Introduction

What types of waste materials can be used for incineration? The power plant uses household waste, cardboard and branches as raw materials, and uses a circulating fluidized bed boiler. When the raw materials are insufficient, coal will be added for incineration.

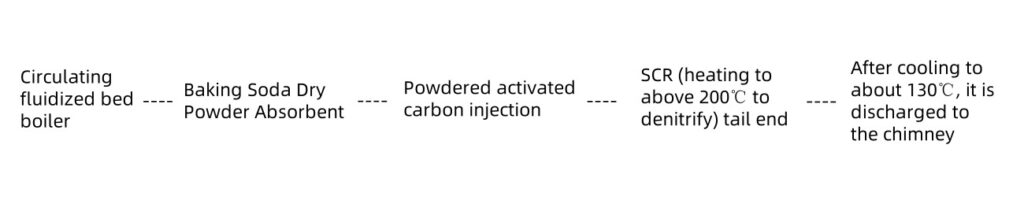

Waste Incineration Process

After the flue gas leaves the circulating fluidized bed boiler, it is first deacidified by dry or semi-dry flue gas. The baking soda dry powder absorbent reacts with acid gases such as HCl, SO2, and HF to generate salts. Powdered activated carbon is then sprayed to remove harmful substances such as dioxins.

Bag dust collection collects reaction products and fly ash to prevent acid gases from entering the subsequent denitrification (SCR) stage. Before the SCR reaction, the flue gas needs to be heated to above 200°C to ensure that the catalyst can effectively remove nitrogen oxides NOx. Finally, it is cooled to 130°C and discharged from the chimney.

You will get a quote in 24 hours

You will get a quote in 24 hours

Custom Heycarbons Activated Carbon Solution

Heycarbons provides a full range of activated solutions at competitive prices.

You will get a quote in 24 hours

What Clients Say on Our Activated Carbon

Customize Heycarbons Activated Carbon

Heycarbons has proudly served the activated charcoal industry with high-quality products since 2005, Heycarb can customize your wood activated charcoal for your project.

- Customize different raw materials according to different applications.

- Customized size, iodine value , methylene blue, molasses value, PH, ash, etc.

- Cost-effective solutions customized according to customer applications.

Steps to Custom Heycarbons Activated Carbon

Consultation

By understanding your needs and requirements, our salesmen work with you to submit the appropriate activated carbon solution.

Quotation

Heycarbons expert customer service will provide you with a free quote based on your requirements as well as product specifications and quantities.

Production

Heycarbons has sufficient inventory and strong production capacity, and will report production progress to you from time to time.

Shipping

Heycarb know you need to receive the product as soon as possible, after rigorous quality checks and protective packaging, by fedex shipping.

Activated Carbon FAQs

Heycarbons provides on demand activated carbon solutions worldwide, product quality and customer service are highly rated by our partners and customers.

- Testing of selected raw materials

- Comprehensive display and monitoring of production temperature and time

- Sampling inspection of finished products

- Support any form of third-party testing , such as SGS

1. T/T Deposiit + Balance against copy of B/L

2. L/C

3. T/T deposit + L/C for balance

1. If necessary, the technician can go to the site to guide .

2. Order goods are consistent with the sample and TDS

3. Any quality problems occur, the seller will provide solutions within 24 hours.

4. If the package is damaged due to the seller’s negligence, resulting in a shortage of goods,

the seller should make compensation based on mutual agreement.

For customers’ trial orders, we actually do not have a specific MOQ, any amount is acceptable.

Heycarb have to choose a cost-effective transportation method and quantity based on your specific situation.

Normally , 5-7days , also depend on quantity

Yes, Heycarb provide samples for free.

Normally 25kgs/bag , 20kgs/bag , 500kgs/bag , black bag

Support any OEM drawing design bag .

Are You Looking for Activated Carbon Manufacturers?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.

You will get a quote in 24 hours