Introduction of activated carbon

Activated carbon is a kind of carbon material with developed pore structure, large specific surface area and strong selective adsorption ability.

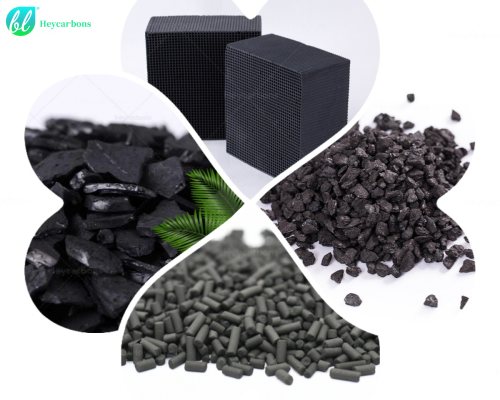

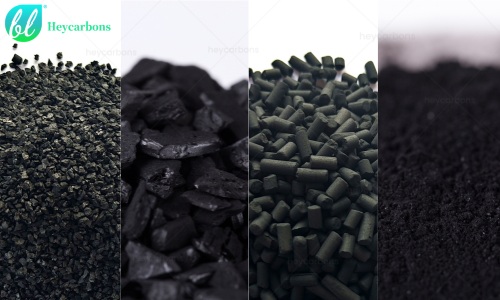

In terms of appearance, activated carbon can be divided into powdered activated carbon, granular activated carbon, extruded activated carbon, columnar activated carbon and so on.

According to the different raw materials, there are common wood activated carbon, fruit shell activated carbon, coal activated carbon and so on.

Under certain conditions, activated carbon can adsorb and remove, purify, refine or recycle a certain substance or certain substances in liquid or gas, realizing the refinement of products and the purification of the environment.

Activated carbon is widely used in various aspects of life and industry, such as chemical industry, foodstuffs, pharmaceutical industry, water treatment, air purification and environmental treatment.

With the development of science and technology and the improvement of people’s living standard, activated carbon has become an indispensable carbon adsorption material in modern industry, living environment and people’s life.

The multifunctionality of activated carbon has made it widely used in various fields, and its unique physical and chemical properties provide it with a huge market potential.

For companies that need activated carbon in the production process, choosing an excellent and reliable activated carbon manufacturer during procurement can not only ensure quality of activated carbon products, but also provide more professional advice, unexpected suggestions and knowledge, thus saving you costs.

So how should we choose and what should we pay attention to during the selection process? This article will answer you one by one.

Why is it recommended to choose a Chinese activated carbon supplier?

China is one of the world’s largest activated carbon manufacturers, and it covers a vast area from cold regions in the north to humid climate zones in the south, and from plains in the east to mountains and plateaus in the west.

This geographical diversity has created rich natural resources, providing abundant raw materials for activated carbon production, such as coconut shells, wood and coal, etc.

This enables activated carbon suppliers in China to provide a variety of types of activated carbon to meet different market demands.

There are many large-scale activated carbon suppliers in China, such as granular activated carbon suppliers, powdered activated carbon suppliers, pelletized activated carbon suppliers, coconut shell activated carbon suppliers, etc.

With China’s rapid industrial development and strong industrial base, activated carbon is produced on a large scale, and suppliers are often able to offer competitive prices, which can significantly reduce production costs for companies that need activated carbon purchased in large quantities.

China continues to innovate in activated carbon production technology, and many suppliers of activated carbon are committed to developing new products and improving production processes to improve the performance and environmental protection of activated carbon.

Chinese products are easily accepted by the international market. Many Chinese activated carbon suppliers have business experience in the international market and are able to follow the standards and certification requirements of the global market, such as ASTM certification, ISO certification and environmental protection standards, ensuring the quality and compliance of their products.

What factors should be considered when choosing an activated carbon supplier in China?

1.Professionalism of Salespersons

When selecting an activated carbon producer, the salesperson’s professionalism, communication skills and international trade experience are crucial.

As a bridge of communication, whether the salesperson has sufficient knowledge of international trade, professional background of activated carbon and logical thinking will directly affect the efficiency of communication and the quality of cooperation between the two sides.

In international trade, salesperson need to be familiar with the entire process from product selection, professional advice, to order management.

They have a clear understanding of trade terms such as FOB and CIF, and be able to choose appropriate logistics, customs declaration and insurance solutions according to customer needs to ensure smooth delivery of orders.

Familiar with export procedures and regulations such as customs declaration, commodity inspection, and shipment to ensure that compliance requirements of the destination country are met to avoid unnecessary delays and costs.

The activated carbon industry involves many technical aspects such as adsorption performance, raw material sources, pore structure, PH, acid washing, quality control, etc.

A qualified salesman should have specialized knowledge of activated carbon to ensure that he is able to understand the technical requirements of the customer and recommend the right type of product.

Salespeople with clear logic can accurately judge the core needs of customers instead of answering in general terms, helping customers find products that meet their needs more quickly.

From quotation, sample confirmation to mass production, salespeople can arrange various tasks in a clear and orderly manner to ensure that orders are completed on time.

In the face of emergencies or urgent needs, salespeople should be able to analyze calmly and quickly provide solutions, while maintaining transparent communication with customers to alleviate their concerns.

2.Qualification of Suppliers

When selecting a supplier, it is important to identify its qualification.

Reputable activated charcoal suppliers are usually willing to accept third-party inspection, such as SGS, to demonstrate their confidence in product quality.

They also accept inspection at the port. When the product is packed and about to be shipped, customers can use the results of the inspection to judge whether the product meets the contractual requirements.

For reputable activated carbon suppliers, port inspections are not only a test of product quality, but also a demonstration of the company’s reputation.

For long-term customers or reputable suppliers, the terms of final payment and refund for non-compliance are a way for both parties to control risks.

The usual arrangement is that after the supplier accepts the third-party inspection and finds that the goods are qualified, the customer pays the final payment and immediately arranges for shipment; if the test result is not up to standard, the customer can choose to change the batch, re-inspect or refund.

Suppliers with good reputation usually cooperate with such terms and conditions positively, because it can enhance the customer’s trust and reduce the customer’s purchasing risk to a certain extent.

Especially in the activated carbon industry, the performance difference will affect the actual application of the product, so many strong suppliers will agree to provide similar guarantee terms and conditions.

The supplier should also have the relevant shipping inspection report and self- heating report, which can ensure the smooth shipment of goods.

How to verify the production capacity and experience of suppliers?

We can ask activated carbon suppliers about their delivery record and on-time delivery rate to see their reliability in delivery.

We can also ask them to provide a sample of activated carbon and conduct a performance test on it to verify whether the product quality meets the requirements.

The production capacity of each production line of activated carbon manufacturers is determined. We can ask the activated charcoal supplier how many corresponding activated carbon production lines they have, the more production lines, the stronger the production capacity.

We can also ask the supplier to send some production videos or the customer directly go to the factory for a site visit. Ask the supplier how the whole production quality management system is.

For special high tech activated carbon, how many relevant experts are there? According to the above methods, we can judge the production capacity and experience of the supplier.

What quality assurance processes should suppliers implement?

In terms of ensuring product quality, activated carbon factories should implement a series of strict quality assurance processes to ensure that high standards are met at every step of the process, from raw material procurement to final delivery.

In terms of raw materials, each batch of raw materials entering the factory is subject to strict quality inspection to ensure that it meets the standards of activated carbon production.

During the production process, suppliers must formulate detailed production process standards, clarify the operating specifications and quality control points for each production link to ensure that each step is documented.

Real-time monitoring of key parameters (such as temperature, pressure, time, etc.) ensures production stability and product consistency.

Automate production, improve visualization and ensure production stability.

Finished product inspection is an indispensable step in quality control to ensure that each batch of ex-factory activated carbon meets customer needs and industry standards.

3.Quality of the Product

When selecting an activated carbon supplier, we learned to evaluate the quality of the product.

The key indicators of high-quality activated carbon mainly include the following aspects: specific surface area, iodine value, ash content, carbon tetrachloride adsorption value, pH, etc.

If you want to know more about these indicators, you can read another of our articles: A Guide to Activated Carbon Parameters: Iodine Value, PH, Methylene Blue, Specific Surface Area, Ash, CTC etc. Together, they determine the performance and effect of activated carbon in different applications.

When purchasing activated carbon, paying attention to these indicators and communicating with suppliers of activated charcoal can help us choose the product that best meets our needs, so as to appreciate the best use effect.

After expressing our needs, the supplier will usually provide a sample of activated carbon, which we can give to a third party for performance testing to verify whether the quality of its product meets our requirements.

So what is the role of third-party testing and certification in quality assurance that we’ve mentioned so often above?

Third-party testing organizations, such as SGS, Intertek and BV, are independent of suppliers and customers and are not influenced by the interests of either party.

Various performance tests of activated carbon through third-party testing organizations can provide objective and fair proof of product quality and help suppliers ensure that their products are in compliance with industry standards, such as ASTM and ISO.

4.Cost and Pricing

When choosing a manufacturer of activated charcoal, cost and pricing are also one of the necessary factors to consider. It is vital to ensure that the price is competitive without compromising quality.

The production process of activated carbon is complex, with a variety of factors affecting the cost, from the selection of raw materials to the fine control of the production process.

Therefore, in order to control costs while maintaining product quality requires optimization in purchasing, production and management, rather than fudging the process by lowering the quality of raw materials or reducing production processes.

In ensuring that the price is reasonable, purchasers should have an in-depth understanding of market conditions and price fluctuations, which can help determine whether product prices are competitive.

The price of activated carbon raw materials is affected by the global economy and supply chain. Regular attention to these factors can help regulate prices and respond to the market changes in a timely manner.

Adopting an efficient and stable production process is an effective way to reduce production costs without compromising quality. Reducing manual intervention through automated equipment can improve production efficiency, reduce human errors, and in turn reduce production costs.

Flexible payment terms and transportation is another key factor in choosing a supplier?

When we purchase activated carbon from China, payment terms and transportation costs typically vary depending on the supplier, product category, transaction size and destination.

Typical payment terms are:

(1)Telegraphic Transfer (TT): Telegraphic transfer is a common method of payment, which usually requires buyers to pay 30% of the total amount as a deposit before production begins, and the remaining 70% is paid before production is completed and shipped.

This approach balances the risk for both parties, as the manufacturer receives partial financial security before starting production, and the buyer can check the quality of the product before completing the bulk of the payment.

(2)Letter of Credit (L/C): Letter of credit is a relatively safe payment method and is suitable for orders with larger amounts, especially for new customers or collaborations with which a stable trust relationship has not yet been established.

Different trade terms will divide the shipping and payment responsibilities between the buyer and seller. Below are some common terms and their shipping cost burdens:

(1)EXW (Ex Works): The buyer is responsible for all transportation costs and risks from the supplier’s location. Under this type of clause, the buyer needs to bear more of the transportation arrangements and costs.

(2)FOB (Free on Board): The supplier bears the cost of loading the goods onto the ship, and after that the costs and risks are borne by the buyer. This method is most common in Chinese exports and is suitable for ocean freight buyers.

(3)CIF (Cost, Insurance and Freight): The supplier bears the cost of transportation and insurance until the port of destination. The buyer only needs to pay port charges and customs clearance at the port of destination. Such terms are more convenient for the buyer, but the supplier will include a certain insurance and freight premium in the quotation.

(4)DAP (Delivered at Place) or DDP (Delivered Duty Paid): The seller bears all costs of transportation, customs clearance, import duties at destination and is responsible for delivery to the buyer’s address. Under these terms, the buyer is not responsible for the transportation arrangements which are more costly but very convenient.

How do tariffs and import duties affect the total cost of procurement?

As a cross-border transaction, purchasing activated carbon from China will inevitably involve tariffs and import duties. So, how do tariffs and import duties affect the total cost of procurement?

A tariff is a tax imposed by an importing country on goods imported from abroad. Tariff rates for activated carbon vary from country to country and are usually categorized according to its type, composition and purpose.

Different carbon duty rates may apply if the activated carbon is used for industrial purposes, environmental purposes, or food-grade filtration purposes. In some countries, activated carbon for certain specialized uses may enjoy lower tariffs, or even zero tariffs.

The calculation of tariffs is generally based on the CIF (cost, insurance and freight) value of the goods, and the calculation formula is: tariff = CIF value × tariff rate. This means that if the tariff rate of activated carbon is 10%, the tariff fee is $100 when the CIF value is $1,000.

The increase in tariffs will directly increase the total import cost of goods, and is usually a cost item that companies need to pay special attention to when quoting and pricing.

In addition to tariffs, many countries impose a value-added tax (VAT) or goods and services tax (GST) on imported goods, and the tax rate depends on national and regional policies.

The calculation of VAT is generally based on the CIF value of the goods plus the total amount of tariffs, that is: VAT = (CIF value + tariff) × VAT rate. Taking a 10% VAT rate as an example, if the CIF value of activated carbon is $1,000 and the tariff is $100, the VAT is (1,000+100) × 10% = $110.

VAT increases the sales price of goods in the local market and will affect the purchasing cost of end users. In some countries, if activated carbon is used for VAT-deductible purposes (such as corporate reproduction or commercial sales), companies can apply for tax refunds, but they need to meet local tax refund requirements and conditions.

High tariffs and import duties may lead to a significant increase in the cost of importing activated carbon, thereby affecting competitiveness in the market. In order to reduce the total cost, some companies will adopt the following strategies:

(1)Batch Purchasing: sharing the expense of import duties by adjusting import batches.

(2)Selection of Free Trade Zones or Low Tariff Markets: Take advantage of free trade agreements to enjoy lower tariffs when importing activated carbon and reduce import costs.

(3)Shift to Local Supply: If import duties are too high, some enterprises may consider choosing a local supplier, especially if the quality of activated carbon and the stability of supply are not compromised.

Increases in tariffs and import duties make activated carbon more expensive in importing countries, which affects profitability and market competitiveness.

In addition, VAT can have an impact on our customers’ cash flow and cost budgets, especially when large-scale purchases are required.

The combination of these taxes may force importers to increase their selling prices, which in turn affects our purchasing decisions.

5.Logistics and Supply Chain Management

In activated carbon procurement, we also need to consider logistics and supply chain management.

What logistics options should be considered for importing activated carbon?

The logistics choice of activated carbon should be determined according to its physical properties, usage, destination and shipping time to ensure the quality of the product and shipping efficiency. The following are common logistics methods for activated carbon and their applicable scenarios:

(1)Maritime Transportation: Maritime transportation is the most common logistics method for activated carbon, and is particularly suitable for large-volume, non-urgent shipments.

Due to the high density and large volume of activated carbon, the cost of shipping by sea is relatively low and suitable for long-distance cross-border transportation.

The advantage of sea freight is low transportation costs, suitability for large-volume transportation, and protection of goods in containers.

Its disadvantage is that the shipping time is longer, which is suitable for non-urgent orders and the delivery time needs to be arranged in advance.

Sea freight is usually suitable for orders that do not require high timeliness, such as bulk transportation of industrial activated carbon, and full container transportation (such as 20-foot or 40-foot containers) is usually selected.

(2)Air Transportation: Air transportation is suitable for small-volume, high-value or urgent activated carbon orders, especially for activated carbon used in urgent needs or in high-end applications with higher timeliness of the product, such as certain high-purity or special-purpose activated carbon.

The advantage of air express is its fast transportation speed, which makes it suitable for emergency situations and high-value goods.

Its disadvantage is that shipping costs are high, usually charged by weight and volume, and are not cost-effective for bulk orders.

Air transport is suitable for short-term emergency needs or for special applications, such as special types used in high-end laboratories or the pharmaceutical industry.

(3)Railway Transportation: Railway transportation is faster than maritime transportation and cheaper than air transportation.

However, China Railway does not accept the transportation of activated carbon at present, but multimodal transportation can be selected for overseas sections.

(4)Land Transportation: Land transportation is usually used for domestic logistics or cross-border transportation between neighboring countries, such as from China to Central Asia, Mongolia, etc.

In addition, land transportation is usually used as a link in multimodal transport to provide transshipment for activated carbon from ports or airports to the final destination.

(5)Multimodal Transport: Multimodal transport combines several modes of transport, such as shipping by sea to a port, followed by rail or road transport to the final destination.

Multimodal transportation is particularly well suited for long-distance transportation of activated carbon orders with complex requirements that need to be transported across multiple countries, and can achieve a balance between cost and efficiency.

(6)Transportation of Dangerous Goods: Activated carbon needs to have a sea transport inspection report, an air transport inspection report and a self-heating report when it is transported by sea or air. But multimodal transportation can be selected for overseas sections.

In general, the logistics selection of activated carbon mainly depends on the purchase batch, timeliness requirements, transportation distance and product characteristics.

Maritime transportation is the lowest-cost mode for high-volume purchases; air transportation is suitable for small-volume, high-value, urgent orders; while rail and intermodal transport provide intermediate options.

In addition, possible requirements of transportation of dangerous goods should also be considered during transportation to ensure that the goods can remain efficient and safe before and after arrival.

How important is it to have clear lines of communication with suppliers during the shipping process?

It is also critical to establish clear lines of communication with suppliers during the transportation of activated carbon.

First of all, activated carbon has strict requirements on environmental conditions such as humidity and temperature during transportation, otherwise it is easy to absorb moisture and affect the adsorption effect.

Clear communication helps to ensure that suppliers take appropriate protective measures in their packaging and transportation methods.

Secondly, communication can help quickly deal with unexpected problems in transportation, such as delays, broken packaging or quantity discrepancies, to prevent factory production from stagnating due to supply chain disruptions.

In addition, clear communication channels can also promote the simultaneous understanding of product specifications and quality control requirements by both parties, avoiding disputes caused by inconsistent standards.

What challenges might you face in the logistics of importing activated carbon and how can they be mitigated?

The logistics process of importing activated carbon will face a variety of challenges due to its special properties and requirements for storage conditions. Here are some common challenges and suggestions for coping:

(1)Humidity and Contamination Risks: Activated carbon is highly hygroscopic and easily absorbs moisture and impurities from the air, which may affect its adsorption effect or even cause failure. The quality of activated carbon may be affected if it is exposed to high humidity or pollution during transportation.

Solution: Use moisture-proof packaging, such as sealed plastic bags.

(2)Vibration and Damage during Transportation: If activated carbon is not packaged properly during transportation, it is easy to become powdered or damaged due to vibration and pressure, affecting its use effect.

Solution: Use strong packaging materials to improve the quality of bags. If the transportation volume is large, it can be loaded in batches on pallets to reduce the pressure on individual packages.

(3)Customs Clearance and Legal Compliance: Activated carbon is subject to regulatory restrictions in many countries during the import process, especially in terms of chemicals and environmental protection, and may face strict customs clearance inspections and regulatory compliance requirements.

In addition, different countries also have different import standards and labeling requirements for activated carbon.

Solution: Before importing, you should have a thorough understanding of the regulatory requirements of the destination country to ensure that the product complies with labeling, ingredient and environmental regulations.

Prepare the required certification and testing documents in advance, such as Material Safety Data Sheets (MSDS), to avoid customs clearance delays due to incomplete documents. Work with experienced freight forwarders to ensure smooth customs clearance procedures.

(4)Logistics Timeliness: Activated carbon is a product with fluctuating demand, and a long import cycle may lead to instability in the supply chain. Especially during the peak supply and demand seasons when delays are encountered, which will directly affect the normal operation of downstream customers.

Solution: Make a reasonable inventory plan and forecast demand in advance to cope with unexpected logistics delays; use multiple modes of transportation (such as air or sea transportation) to flexibly ensure the continuity of supply.

Communicate with suppliers and logistics companies regularly to obtain the latest transportation status and arrival time; if the demand is large, you can choose multiple alternative suppliers.

The above measures can effectively alleviate the challenges in the logistics of imported activated carbon. Stable logistics channels and clear supply chain management can help guarantee the quality and continuity of supply of activated carbon, thus better meeting customer needs.

6.After-sales Support and Relations

In the process of selecting an activated carbon factory, after-sales support and the ability to establish a long-term stable supply relationship is also one of the factors we should consider.

What after-sales services should you expect from the supplier?

The after-sales service provided by suppliers is the key to ensure product quality, smooth logistics and efficient application. Here are some of the after-sales services we can expect:

(1)Product Technical Support: The performance and application scenarios of activated carbon vary due to its raw materials and production processes.

Especially in specific application areas (such as water treatment and gas purification), the requirements for adsorption performance are more stringent.

The supplier should provide detailed technical support, including:

– Provide detailed technical information such as product performance data sheets and adsorption isotherms to assist in assessing product suitability.

– Provide corresponding activated carbon recommendations and usage suggestions for different application scenarios.

– Provide expert technical consultation in the process of use to answer questions related to product suitability, adsorption effect, regeneration cycle and so on.

(2)Quality Inspection and Quality Assurance Services: Activated carbon may be affected by external factors during storage and transportation, so quality inspection and quality assurance services are crucial.

The supplier should provide:

– Product inspection report before leaving the factory to ensure that the activated carbon meets the standards, such as particle size, adsorption performance, ash content and other parameters.

– Provide product quality assurance and free replacement or return of products for substandard performance due to quality defects during the validity period.

– Conduct source analysis on quality problems that occur during use and provide solutions.

(3)Logistics Tracking and Delivery Guarantee: the logistics cycle of activated carbon is long, real-time logistics tracking and efficient delivery guarantee can help to reduce the supply chain risk, which suppliers can provide in this regard:

– Provide real-time order tracking services to ensure that buyers can obtain logistics information in real time.

– Inform potential risks of transportation delay in advance and propose response plans to reduce the impact on production schedules.

– Provide emergency delivery or replenishment support when necessary to ensure the stability of production and inventory.

(4)Training and Application Guidance: In order to maximize the use of activated carbon, producers can provide customers with corresponding training and application guidance. The specific contents include:

– Organize training for technicians or operators to introduce the characteristics of activated carbon, precautions for use, and operating specifications in different application scenarios.

– Instruct customers on how to monitor the working status of activated carbon, such as adsorption saturation testing methods and replacement cycle.

– Provide on-site technical support at the beginning of the project to ensure that the activated carbon is applied as expected.

(5)Customer Feedback and Improvement Support: The communication and feedback mechanism between suppliers and customers helps to continuously improve product quality and service. Customers can expect:

– Regular satisfaction surveys to understand customers’ evaluation and needs for products and services.

– In response to the customer’s suggestions for improvement, activated carbon suppliers should provide timely feedback and consider applying them in subsequent product improvements.

– Provide customer service specialists to respond quickly to after-sales issues and ensure that customer problems are resolved in a timely manner.

By providing comprehensive after-sales services, suppliers can help customers reduce risks and improve the user experience during use, and ensure that the performance of activated carbon is effectively utilized throughout its entire life cycle.

This not only enhances customer confidence in the product, but also builds a good reputation and cooperative relationship for the supplier.

What common problems may arise after purchase and how should they be solved?

After purchasing activated carbon, there are a number of problems that may arise during its use. Understanding these common problems and having a plan to deal with them will help ensure the effectiveness and longevity of the activated carbon.

If the adsorption effect of activated carbon fails to meet expectations, resulting in failure to achieve the expected results in applications such as water treatment and air purification, the reasons may include improper product selection, adsorption saturation reaching the upper limit, environmental conditions not meeting the use requirements, and product failure to meet standards.

In this regard, we can confirm that the specifications of the selected activated carbon match the needs of the application, e.g. using activated carbons with different pore sizes and surface areas for different adsorbents.

Activated carbon needs to be replaced or regenerated after adsorption is saturated. A reasonable replacement cycle should be formulated according to the application scenario.

It is also important to ensure that the environment in which the activated carbon is used meets the optimal working conditions, especially humidity and temperature.

If the humidity is too high, choose a product with high humidity resistance or use it in a low humidity environment.

During use, some activated carbons may generate fine powder or dust, especially when they are subjected to vibration during transportation or handling. This dust may affect the filtration equipment or contaminate the air or water to be treated.

We can add a primary filtration layer to the equipment using activated carbon to prevent fine powder from entering the system. Some activated carbon filter manufacturers often do this.

Activated carbon tends to absorb moisture or airborne impurities during storage, which reduces its surface area and affects its adsorption performance.

In this regard, we need to store activated carbon in a dry and sealed container to avoid contact with moisture and pollutants in the air, or in a ventilated, dry and low-temperature environment to avoid direct sunlight.

Try to use it within a short period of time, especially in high humidity or polluted environments where long term storage can significantly affect the adsorption capacity.

7. Case Studies and Success Stories

In terms of selecting and managing activated carbon suppliers, many companies have successfully achieved quality assurance and cost control by optimizing cooperative relationships, while ensuring the stability of the supply chain.

By studying successful cooperation cases with suppliers, we can effectively screen suppliers.

Summary

With the deepening of global economic integration, choosing a reliable activated charcoal manufacturer is crucial to ensure the sustainable development of the business.

We hope that this article provides you with useful information and guidance to help you identify activated carbon manufacturers that can meet your specific needs.

By building strong partnerships, you will be able to ensure the stability of your supply chain, improve business efficiencies, and ultimately achieve both cost-effectiveness and environmental benefits.

Remember, choosing a supplier is not just a one-time transaction, but a long-term relationship.

Thanks for your reading. We look forward to establishing a mutually beneficial and win-win relationship with you in the future.