Gold Recovery Activated Carbon Video:

1.What are the mainstream methods for gold extraction?

CIP (Carbon in Pulp), CIL (Carbon in Leach) and CIC (Carbon in Column) are three common methods for gold extraction, and the main differences are in the treatment process and process design. The following is a brief introduction to the three methods:

1) CIP (Carbon in Pulp)

*Process flow:

1.Crushing and grinding: crush and grind the gold ore into fine powder.

2.Leaching: mix the fine powder ore with cyanide solution to leach gold.

3.Adsorption: mix the leaching solution with activated carbon, and the gold is adsorbed onto the activated carbon.

4.Desorption and electrolysis: Desorb gold with hot alkaline solution, and then deposit gold by electrolysis.

5.Smelting: Smelt gold mud into pure gold.

*Advantages:

Activated carbon is in direct contact with the slurry during the whole process, and the gold adsorption efficiency is high.

Suitable for low-grade ores with high recovery rate.

2) CIL (Carbon in Leach)

*Process flow:

1. Crushing and grinding: Crushing and grinding gold ore into fine powder.

2. Combined leaching and adsorption: Mix fine powder ore with cyanide solution and activated carbon, and leaching and adsorption of gold are carried out simultaneously.

3. Desorption and electrolysis: Desorb gold with hot alkaline solution, and then deposit gold by electrolysis.

4. Smelting: Smelt gold mud into pure gold.

*Advantages:

Leaching and adsorption are carried out simultaneously, and the process flow is simplified.

The processing time is short, which is suitable for processing ores containing carbonaceous substances.

3) CIC (Carbon in Column)

*Process flow:

1.Crushing and grinding: crush and grind the gold ore into fine powder.

2. Leaching: mix the fine powder ore with cyanide solution to leach gold.

3. Column adsorption: pass the leaching solution through an adsorption column filled with activated carbon, and the gold is adsorbed on the activated carbon.

4.Desorption and electrolysis: desorb the gold with hot alkaline solution, and then deposit the gold by electrolysis.

5. Smelting: smelt the gold mud into pure gold.

*Advantages:

Suitable for treating low-concentration gold solution, especially tailings treatment.

High adsorption efficiency and simple process flow.

Summary

CIP is suitable for situations where high adsorption efficiency is required and low-grade ores are treated.

CIL is suitable for carbon-containing ores and situations where the process needs to be simplified and the treatment time needs to be shortened.

CIC is suitable for treating low-concentration gold solutions and tailings reprocessing.

When choosing a specific method, it is necessary to consider a variety of factors such as ore properties, gold content, economy and environmental protection.

2. 16keys to judge the quality of coconut shell activated carbon for Gold Recovery?

1) Thickness of Gold Recovery Activated Carbon

The origin of the raw material and the growth age of the coconut tree determine the thickness of the coconut shell, which in turn affects the thickness of the activated carbon. The thicker it is, the stronger it is. The stronger it is, the less likely it is to produce debris during use, and it is not easy to cause the loss of gold.

2) Iodine value

The higher the iodine value, the stronger the adsorption capacity. If the iodine value is too high, its strength will decrease, because it represents more internal pores, which requires finding a balance. Therefore, the iodine value that is generally used is between 1000 and 1100.

3) Ash content

Excessive ash content will reduce the adsorption performance of activated carbon, increase conductivity, and affect mechanical strength. Low ash content indicates that the activated carbon is of high purity and good adsorption effect.

4) Moisture content

The moisture content affects the adsorption performance of activated carbon. Excessive moisture will occupy the adsorption site and reduce the adsorption capacity of the target substance.

5) Strength

Mechanical strength evaluates the ability of activated carbon to resist pulverization and abrasion during use. Higher mechanical strength ensures that it maintains structural integrity during use and prolongs its service life.

Usually, the thicker the coconut shell, the higher its mechanical strength. However, under the same thickness, its selection criteria are different, and its strength is also different. The reason is that the density of coconut shell is also different, which will also affect the strength.

In the absence of experimental conditions, different samples can be rubbed on paper to judge the strength by the amount of dust produced.

6) Bulk density

Under the same iodine value and moisture, the higher the bulk density means the denser its texture, and then the stronger its strength. Bulk density affects the filling amount and overall adsorption capacity of activated carbon. A higher bulk density means that there are more activated carbon particles per unit volume, and the adsorption performance is better.

7) Attrition

Low Attrition. Low gold loss rate

8) R value of Gold Extraction Activated Carbon

“R value represents the speed of gold adsorption per unit weight of activated carbon per unit time:

9) K value of Gold Extraction Activated Carbon

K value represents the capacity of activated carbon to adsorb gold per unit weight, but if the K value is higher, the iodine value is higher, more 1nm micropores, and the hardness decreases, more debris is produced. Based on the order of magnitude of 5kg gold adsorbed per ton of carbon, for every 1% loss of debris, 50g of gold will be lost per ton of activated carbon that has been adsorbed.

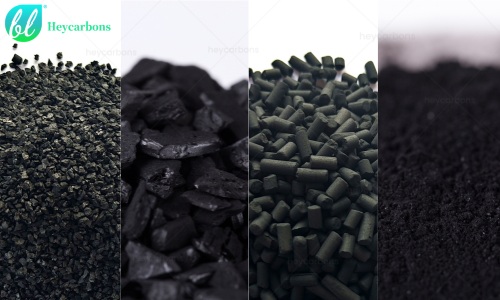

10) Particle uniformity

Due to different crushing methods, the same size looks very different in appearance. A good appearance should be rounded and less angular. (Contact us to explain more crushing methods) . Of course, it can also be achieved by grinding, but the cost will be greatly increased. Therefore, it is very important to choose an advanced crushing method.

11)Cleanliness

That is, activated carbon with less dust will save customers time and water for rinsing. Of course, you can also ask the manufacturer to wash it with water, but the drying process after washing greatly increases the cost and has a low cost performance.

12)Bubbling

In the absence of testing equipment, put the activated carbon in water. The more intense and longer the bubbling, the better the adsorption performance. However, the intensity of bubbling and the bubbling time should be combined for comprehensive judgment. Because some carbons with high density do not bubble as violently as those with low density at the beginning, but they last longer.

13)Equipment test of gold absorption.

If conditions permit, it can be used under laboratory conditions. Use a gold test furnace to test the gold absorption capacity.

14) Production process

Generally speaking, coconut shell activated carbon produced by a slep furnace has higher strength, but because it is slow to increase the iodine value, it can only reach 1150 iodine value at most, but its strength is very high and the price will be higher (because of the long time and high cost). However, coconut shell activated carbon produced by a converter can reach 1700 iodine value at most because of its fast iodine value, but its strength will be lower and the price will be slightly cheaper.

15) Low Platelets

Lower Platelets also determines the loss rate of gold, because the strength of the flakes is low. If the overall strength of the supplier’s activated carbon is very high, but if he does not remove the flakes, then his gold loss rate is also high.

16) Is the finished product polished?

After polishing, the activated carbon for gold extraction has a more regular shape and fewer edges and corners. The less debris will be generated during use, and the gold loss rate will be lower.

3. How to choose suppliers of Coconut Shell Activated Carbon for Gold Recovery ? and price influencing factors ?

Lower Platelets also determines the loss rate of gold, because the strength of the flakes is low. If the overall strength of the supplier’s activated carbon is very high, but if he does not remove the flakes, then his gold loss rate is also high.

4. Advantages of Heycarbons activated carbon in gold recovery

1) Select coconut tree production areas that have grown for more than 5 years. Ensure that the coconut shell thickness reaches 5-8mm. Then remove the palm hair. Ensure that the finished product has a lower ash content.

2) Slep furnace production. The strength of our golden carbon can reach more than 98%. CIP pays more attention to the strength of coconut shell activated carbon, and you can choose our super golden carbon. The strength can reach more than 99%

3) Wind selection removes flakes and reduces the gold loss rate.

Platelets <4%

4) Our crushing method determines that our particles are more uniform. Reduce the generation of debris. Attrition< 1%

5) Free sample testing. It is your right to choose a more cost-effective product.

6) CIC customers can choose our coconut shell columnar activated carbon.

7) Adhering to low gross profit margin makes our comprehensive competitiveness exceed 95% of our peers.

8) We use Slep furnace to activate coconut shell activated carbon for gold extraction, with the same iodine value, higher specific surface area and better strength.

Recently, One customer from Egypt visiting our company, who had been purchasing coconut shell activated carbon from the Indian market many years. After visiting and comparing, he found that our activated carbon is of better quality. Although our price is slightly higher, the overall cost-performance ratio is better. He is willing to try a trial order of 55 tons with the intention of establishing a long-term cooperation.

Please check the video to view quality control production process of coconut shell granular activated carbon for gold recovery :

Carbonized material is dusted and removed before entering the silo, and the silo enters the activation furnace through the elevator.

After being activated by the Slep furnace, it enters the crushing, screening and dust collector through the underground pipeline (the dust collector ensures that the activated carbon has less external ash and is clean). The 4 large dust collectors work continuously to ensure that the cleanliness of the goods exceeds 98% of domestic peers.

After crushing and screening, it enters the grinder on this side, and the scraps are polished on the other side. The polished activated carbon is more rounded and full, which will reduce wear and reduce the gold loss rate during use. The scraps we polished are screened for water treatment.

After polishing, it enters our wind selection and flake removal machine. The flake removal machine is based on the combination of wind power and gravity. Remove the thinner parts. Ensure the thickness and strength of each of our coconut shell gold activated carbon.

This is our finished product.

Contact us to provide customers with test results of our samples and the gold absorption capacity of other samples. And get samples for free.

5. Activation process of activated carbon for gold extraction: the difference between Slep furnace and rotary furnace

1. Process principle and structure

Rotary kiln

Principle: Through the slowly rotating horizontal drum, coconut shell charcoal is brought into contact with an activator (such as water vapor or flue gas) at high temperature (usually 600–900°C) to achieve physical activation.

Features: Continuous production, uniform heating of materials, but the temperature and residence time control accuracy is low, and local overburning or insufficient activation is prone to occur.

SLEP furnace

Principle: It adopts a vertical multi-chamber structure, and chemically activates the coconut shell charcoal by alternating the airflow direction (up and down circulation) using high-temperature fuel gas (such as coal gas) to react with coconut shell activated carbon.

Features: Temperature control in stages (preheating, activation, cooling), more precise temperature gradient (usually 800-950℃), better activation uniformity, but it belongs to intermittent production.

2. Product performance differences

| Project | Rotary furnace | SLEP furnace |

|---|---|---|

| Activation uniformity | Generally, the carbon material is tumbled and mixed but the residence time is inconsistent | Very high, thick carbon layer, long residence time and uniform |

| Pore structure | Mainly mesopores, with a wide pore size distribution | Well-developed micropores, suitable for adsorption of gold ions |

| Specific surface area | 800–1200 m²/g | 1000–1500 m²/g(higher) |

| Gold absorption capacity | Qualified | Excellent |

3. Production efficiency and cost

Rotary furnace

- Continuous production, high production capacity (suitable for large-scale), low energy consumption;

- But the raw material loss rate is high (about 20-30%), and the product consistency is slightly poor.

SLEP furnace

- Intermittent production, long cycle (24-48 hours/furnace), high energy consumption;

- High raw material utilization (loss of about 10-15%), stable product quality, suitable for high value-added applications.

4. Applicable scenarios

Rotary furnace activated carbon

Commonly used in water treatment, food decolorization, chemical filtration and other fields that do not require strict pore size.

Slep furnace activated carbon

Used in high-end gas phase adsorption (such as gas masks, gold extraction), supercapacitor electrode materials and other scenes that require high microporosity.

In the coconut shell activated carbon for gold recovery production process, Heycarbons factory uses slep furnace for activation. The activated carbon produced has well-developed micropores, high hardness, strong gold absorption ability, can be repeatedly regenerated, and has few impurities. Therefore, the cost of activated carbon produced by slep furnace is slightly higher than that of rotary furnace.

The slep furnace used by heycarbons to produce activated carbon is equipped with a gas system. The exhaust gas is discharged after desulfurization treatment, and the dust is well controlled, which has little pollution to the environment.

Heycarbons also has rotary furnace for activation. The activated carbon produced is suitable for use in water purification, food and other fields.

Heycarbons specializes in producing high-quality coconut shell activated carbon for gold CIP/CIL process.