1.Introduction to Acid Washed Activated Carbon

Acid washed activated carbon is a highly specialized form of activated carbon that undergoes a unique acid-washing process to remove impurities such as heavy metals and ash. This treatment enhances its performance in water purification and other industrial applications, making it an indispensable material in processes requiring ultra-pure filtration systems.

Activated carbon is known for its excellent adsorption properties, making it useful for removing contaminants like chlorine, organic compounds, and odors from water. However, the acid washing process takes this efficiency a step further, delivering a purer and more effective product for industries that demand the highest standards of cleanliness.

1.What is Activated Carbon?

Activated carbon, sometimes referred to as activated charcoal, is a porous material with a high surface area. This unique structure allows it to trap impurities from liquids and gases, making it a key component in filtration and purification systems. It is commonly made from organic materials such as coconut shells, coal, or wood, which are then heated in an oxygen-free environment to “activate” the carbon. This activation process significantly increases the carbon’s surface area and enhances its ability to adsorb contaminants.

2.What Makes Acid Washed Activated Carbon Different?

Acid washed activated carbon undergoes an additional process that differentiates it from standard activated carbon. During the acid washing phase, carbon is treated with hydrochloric acid, which removes metallic impurities like iron, calcium, and magnesium. This results in a material with significantly lower ash content and fewer soluble impurities.

The acid washing process not only reduces contaminants but also adjusts the pH levels, making the carbon more suitable for applications where low pH is required. The end product is cleaner, more durable, and capable of longer operational life.

3.Why Acid Washed Activated Carbon is Essential for Industrial Applications

The specific treatment processes that acid washed activated carbon undergoes make it ideal for numerous applications across different industries, including:

– Water Treatment: Due to its enhanced ability to remove chlorine, organic compounds, and other impurities, acid washed activated carbon is commonly used in water purification, particularly in systems like reverse osmosis (RO) filters. Its low pH levels make it compatible with sensitive applications requiring stable, neutral pH water, such as drinking water systems and industrial water treatment plants.

– Food and Beverage: This form of carbon is highly effective at removing unwanted tastes, odors, and organic contaminants from water and other liquids. It is particularly useful in the production of beverages like soft drinks, beer, and other liquids that demand high purity.

– Pharmaceuticals: Acid washed activated carbon is also used in the pharmaceutical industry, particularly in dialysis and other medical filtration systems, where ultra-pure water is essential for patient safety.

– Electronics and Semi-Conductor Industries: In these high-precision fields, even the smallest impurities can cause defects or failures. Acid washed carbon is often used in ultra-pure water treatment systems in the production of electronics and semiconductors.

These applications demonstrate the versatility and critical importance of acid washed activated carbon in industries where the purity and performance of filtration systems are paramount.

4.Conclusion: The Key to Superior Adsorption and Cleaner Water

Acid washed activated carbon stands out as a top choice for industrial applications requiring ultra-pure filtration solutions. Its ability to remove heavy metals, organic compounds, and chlorine makes it indispensable in industries ranging from water treatment to food and beverage production. Moreover, its enhanced longevity and low pH compatibility ensure that systems remain functional and cost-effective for extended periods.

2.The Acid Washing Process – How It Improves Adsorption Properties

Acid washed activated carbon is well-known for its enhanced adsorption properties, which make it far superior to untreated activated carbon for certain high-purity applications. The key to this improvement lies in the acid washing process itself, which involves treating the carbon with an acid—usually hydrochloric acid—to remove impurities like heavy metals, ash, and calcium carbonate from its internal structure. This meticulous process not only improves the carbon’s adsorption capacity but also extends its operational life and reduces issues like dusting and black water formation.

1.What Happens During the Acid Washing Process?

Activated carbon is produced from raw materials like coconut shells, coal, or wood. These materials are carbonized at high temperatures to create a porous structure. While activated carbon is already effective at trapping contaminants due to its high surface area, it can still contain small amounts of impurities, including heavy metals, calcium, and other inorganic salts, which reduce its efficiency.

In the acid washing process:

- Hydrochloric acid is introduced to the activated carbon, dissolving inorganic salts and metal impurities that might otherwise interfere with adsorption.

- Leaching and flushing: The acid-treated carbon is then flushed with water to remove any dissolved metals, reducing ash content and improving purity.

- pH adjustment: Acid washing helps neutralize the pH of the activated carbon, making it suitable for sensitive applications where pH balance is critical, such as in drinking water treatment and industrial processes requiring low pH.

The process yields a cleaner, more efficient activated carbon that performs better in high-purity systems. By removing these impurities, the carbon can adsorb contaminants more effectively, leading to better filtration performance and extended filter lifespan.

2.How Acid Washing Enhances Adsorption Properties

Activated carbon’s performance is heavily influenced by its surface area, pore structure, and the presence of impurities. Acid washing removes surface contaminants, leaving more active sites available for adsorption. Here’s how this process enhances its adsorption capabilities:

- Increased Pore Availability: Acid washing opens up the micropores within the carbon, allowing for greater surface area and more effective adsorption of organic compounds, chlorine, and other contaminants. This increased pore availability is especially important in applications like water purification and air filtration.

- Reduced Ash Content: Ash is a byproduct of the carbonization process and can block the activated carbon’s pores, reducing its adsorption capacity. Acid washing removes this ash, which can be as high as 5% in untreated carbon, and reduces it to less than 1% in high-quality acid washed carbon.

- Improved Contaminant Removal: By reducing heavy metals and other impurities, acid washed carbon is more effective at removing unwanted chemicals, including volatile organic compounds (VOCs), chloramines, and odors from water and air.

- Lower Risk of Black Water: One common issue with non-acid washed carbon is the formation of “black water,” caused by the release of fine carbon particles into the filtration system. Acid washing reduces surface dust and minimizes the risk of black water formation, particularly in water treatment systems.

3.Why Acid Washed Activated Carbon is Preferred in High-Purity Applications

Acid washed activated carbon is favored in industries requiring extreme levels of purity. Its ability to effectively adsorb organic and inorganic compounds, combined with its reduced ash and heavy metal content, makes it a premium choice in:

– Pharmaceutical and Medical Applications: In dialysis and other medical treatments, the purity of water is paramount. Acid washed activated carbon helps remove impurities that could interfere with patient care.

– Food and Beverage Production: In beverage manufacturing, especially in soft drinks and breweries, any contaminant that alters the taste or safety of the product must be removed. Acid washed carbon ensures that only the highest quality water is used.

– Semi-Conductor and Electronics Manufacturing: These industries require ultra-pure water to prevent defects in their products. Acid washed activated carbon is used in water purification systems to meet these exacting standards.

4.Conclusion: The Essential Role of Acid Washing in Activated Carbon

The acid washing process significantly enhances the effectiveness of activated carbon, making it indispensable for industries that require high-purity filtration. By increasing the available surface area, reducing ash content, and removing heavy metals, acid washed activated carbon can provide superior adsorption performance, longer operational life, and fewer maintenance issues like black water formation.

As the demand for cleaner water and air continues to grow, the use of acid washed activated carbon is likely to become even more widespread in industries ranging from pharmaceuticals to electronics. For anyone looking to optimize their filtration systems, acid washed activated carbon offers the purity and performance necessary to meet stringent regulatory and operational demands.

3.Key Applications of Acid Washed Activated Carbon in Various Industries

Acid washed activated carbon is a versatile and highly effective material used across multiple industries due to its enhanced purification and filtration capabilities. The acid washing process removes impurities like heavy metals and ash, improving the carbon’s efficiency in adsorbing organic compounds, chlorine, and odors. This makes it indispensable for industries that require high-purity results, ranging from water treatment plants to food production and even medical applications. Below, we explore the key applications and why acid washed activated carbon is the preferred choice in these fields.

1. Water Treatment: Ensuring Clean and Safe Drinking Water

One of the primary uses of acid washed activated carbon is in water treatment systems. Its ability to remove chlorine, chloramine, and other contaminants ensures that the water is safe and palatable. Whether used in municipal water treatment plants or home filtration systems, acid washed carbon helps provide cleaner and better-tasting water.

Key benefits in water treatment:

– Dechlorination: Acid washed activated carbon is particularly effective in removing chlorine and chloramines, which are commonly used to disinfect water but can leave behind undesirable tastes and odors.

– Organic Contaminant Removal: It also adsorbs volatile organic compounds (VOCs), making it ideal for both large-scale water purification plants and residential filtration systems.

– Protection of Reverse Osmosis (RO) Membranes: Acid washed activated carbon is frequently used in conjunction with reverse osmosis systems to protect delicate membranes from chlorine and organic fouling.

2. Food and Beverage Industry: Purity in Every Sip and Bite

In the food and beverage industry, maintaining product purity is critical to both safety and flavor. Acid washed activated carbon plays a vital role in ensuring that water used in production processes is free from contaminants that could affect the taste or safety of the final product. It is especially popular in the manufacturing of soft drinks, beer, and spirits.

Key applications in food and beverage production:

– Odor and Taste Removal: The carbon removes organic impurities that might alter the taste and aroma of beverages.

– Filtration in Breweries and Distilleries: In alcohol production, where water purity is paramount, acid washed carbon ensures a clean, high-quality product

– Compliance with Food Safety Standards: The purity of acid washed activated carbon ensures compliance with strict regulations in food production facilities.

3. Pharmaceuticals: Ultra-Pure Filtration for Medical Applications

The pharmaceutical industry is another area where acid washed activated carbon is essential. The carbon’s ability to remove even trace amounts of organic and inorganic contaminants makes it ideal for applications that require ultra-pure water, such as dialysis and other medical treatments.

Key uses in pharmaceuticals:

– Dialysis Water Filtration: Acid washed carbon is used in the preparation of water for dialysis, removing impurities that could harm patients.

– Pharmaceutical Production: In the manufacturing of medicines and treatments, clean water free from contaminants is crucial. Acid washed carbon ensures that pharmaceutical products meet stringent quality and safety standards.

4. Electronics and Semi-Conductor Manufacturing: Preventing Contaminants in Ultra-Pure Water

In industries like electronics and semi-conductor manufacturing, even the smallest impurities can cause defects in products. Acid washed activated carbon is widely used to purify water that comes into contact with electronic components, ensuring that no harmful contaminants interfere with production.

Key advantages in electronics:

– High-Purity Water Treatment: Acid washed carbon ensures that water used in semi-conductor production is free from contaminants that could damage sensitive components.

– Consistency and Reliability: The controlled pH and purity of acid washed carbon make it a reliable component in maintaining consistent production quality.

5. Industrial Air Filtration and Pollution Control

Another emerging application of acid washed activated carbon is in air filtration systems. As industries seek to reduce their environmental impact, the ability of acid washed carbon to adsorb harmful gases and volatile organic compounds (VOCs) makes it an ideal solution for air purification.

Key uses in air filtration:

– VOCs and Odor Removal: Acid washed carbon can efficiently remove VOCs and odors from industrial exhausts, contributing to a cleaner environment.

– Pollution Control: By removing hazardous gases, acid washed carbon helps industries comply with environmental regulations and reduce their carbon footprint.

Conclusion: The Versatility of Acid Washed Activated Carbon

The applications of acid washed activated carbon extend across a broad range of industries, from ensuring clean drinking water to protecting sensitive electronic components. Its superior ability to adsorb contaminants, combined with its low ash content and extended operational life, makes it a critical material for industrial processes where purity and performance are non-negotiable.

Whether you’re in food production, water treatment, or pharmaceuticals, acid washed activated carbon provides the clean, reliable filtration needed to meet industry standards and enhance product quality. For more information on how acid washed activated carbon can be tailored to your specific needs—

Here is a comparison chart displaying the key differences between acid-washed activated carbon and non-acid-washed activated carbon:

| Properties | Acid-Washed Activated Carbon | Non-Acid-Washed Activated Carbon |

| pH Level | 7.5 | 9.0 |

| Filtration Efficiency (%) | 95 | 85 |

| Water Purity (%) | 99.5 | 90 |

| Ash Content (%) | 0.2-1%,2%,3%,5%,8% | 3%,6%,8%,12%,15% |

| Heavy Metal Content (%) | 0.01%,0.02% | 0.2 , 0.5,0.6 |

This table highlights the improved pH balance, higher filtration efficiency, and reduced ash and heavy metal content in acid-washed activated carbon, making it ideal for more sensitive and high-purity applications compared to its non-acid-washed counterpart.

4.Acid Washed Activated Carbon for Water Purification – Ensuring Cleaner, Safer Water

Water purification is one of the most critical applications of acid washed activated carbon, especially in industries and settings where water quality must meet high standards for safety and taste. Whether it’s municipal water supplies, industrial processes, or even residential filtration systems, acid washed activated carbon plays a pivotal role in ensuring that the water we consume is free from harmful contaminants like chlorine, organic compounds, and heavy metals. In this section, we’ll dive deep into the specifics of how this material improves water quality and enhances filtration systems.

1.How Acid Washed Activated Carbon Works in Water Purification

The primary function of acid washed activated carbon in water purification is adsorption, a process where contaminants adhere to the surface of the carbon particles. Activated carbon has an exceptionally high surface area, and the acid washing process further enhances its adsorption capacity by removing impurities that could block the pores.

Key contaminants removed include:

- Chlorine and Chloramines: These disinfectants are commonly used to treat water but often leave behind unpleasant tastes and odors. Acid washed activated carbon effectively removes these compounds, ensuring water is both safe and palatable.

- Volatile Organic Compounds (VOCs): Many organic chemicals that enter water systems from industrial runoff or agricultural processes can affect water quality. Acid washed carbon adsorbs these VOCs, preventing them from contaminating drinking water supplies.

- Heavy Metals and Inorganic Impurities: During the acid washing process, impurities like iron, magnesium, and calcium are dissolved and removed, significantly reducing the levels of heavy metals that might leach into the water. This is particularly important in applications where water needs to be ultra-pure, such as in dialysis or the production of pharmaceuticals.

By incorporating acid washed activated carbon into water filtration systems, facilities can dramatically improve the quality of water, making it safe for consumption, industrial use, or even environmental release.

2.Protecting Reverse Osmosis (RO) Membranes

One of the most critical applications of acid washed activated carbon in water purification is in reverse osmosis (RO) systems. RO membranes are incredibly sensitive to contaminants like chlorine and organic fouling, which can degrade their performance over time. Acid washed activated carbon acts as a pre-filter in these systems, removing chlorine and other chemicals before they can damage the membranes.

Key benefits for RO systems include:

– Chlorine removal: RO membranes are vulnerable to chlorine, which can degrade their structure. Acid washed carbon neutralizes chlorine, extending the life of the RO membranes.

– Prevention of Organic Fouling: Organic fouling occurs when organic substances clog the pores of RO membranes, reducing their efficiency. Acid washed activated carbon adsorbs these organic compounds before they can cause fouling.

– Improved Water Quality: By removing contaminants early in the filtration process, acid washed activated carbon ensures that the RO system produces higher-quality water, reducing the need for frequent membrane replacement.

3.Dechlorination: Removing Unwanted Tastes and Odors

Chlorine and chloramine are commonly added to water supplies to disinfect and kill harmful pathogens. While effective for disinfection, these chemicals often leave behind unwanted tastes and odors, which can affect both the quality and safety of drinking water. Acid washed activated carbon excels in dechlorination, removing these disinfectants and restoring water to its natural, clean taste.

Applications of dechlorination:

– Municipal Water Supplies: In large-scale water treatment plants, acid washed carbon helps remove chlorine from treated water before it is distributed to homes and businesses.

– Residential Filtration Systems: Many home water filters use acid washed activated carbon to improve the taste of tap water by removing chlorine and other contaminants.

– Industrial Water Treatment: In industries that rely on water with specific taste or chemical properties (like food and beverage production), dechlorination using acid washed carbon ensures that water meets stringent quality standards.

Reducing Organic Contaminants and Improving Water Safety

Organic contaminants, including pesticides, herbicides, and industrial chemicals, are a growing concern in water supplies. These compounds can pose significant health risks and must be removed before water is deemed safe for consumption. Acid washed activated carbon is highly effective at adsorbing these organic contaminants, ensuring that the water is free from harmful chemicals.

Key benefits in water safety:

– Removal of Synthetic Organic Chemicals: Acid washed carbon adsorbs synthetic organic chemicals that may have entered the water supply from industrial runoff, agriculture, or urban sources.

– Improved Health Outcomes: By reducing the presence of harmful organic compounds in drinking water, acid washed activated carbon helps protect public health and meet regulatory standards for safe water.

4.Conclusion: Cleaner Water for Healthier Communities

Acid washed activated carbon is an indispensable material in the realm of water purification. Its ability to remove harmful contaminants like chlorine, VOCs, and heavy metals makes it a vital component of water treatment systems across various industries. Whether used to improve the taste of drinking water or to protect sensitive RO membranes, acid washed activated carbon plays a crucial role in ensuring that the water we use and consume is safe, clean, and free from harmful substances.

For industries and municipalities seeking to enhance their water purification processes, investing in acid washed activated carbon is a step toward a cleaner, safer future.

5.Technical Specifications – Choosing the Right Acid Washed Activated Carbon for Your Needs

When selecting the right acid washed activated carbon for specific industrial or commercial applications, understanding its technical specifications is essential. Various factors, such as particle size, iodine number, hardness, and adsorption capacity, play crucial roles in determining the effectiveness of the carbon for different filtration and purification tasks. By understanding these specifications, you can ensure the best performance for your water treatment, air purification, or other processes that require high-purity filtration.

1. Iodine Number – A Key Indicator of Adsorption Capacity

The iodine number is one of the most critical specifications when it comes to evaluating the adsorption capacity of acid washed activated carbon. This number measures how much iodine the carbon can adsorb and is often used as a benchmark to gauge its effectiveness for removing organic contaminants.

– High Iodine Number: A higher iodine number generally indicates a greater surface area and, therefore, a better capacity to adsorb small organic molecules. For example, most high-quality acid washed activated carbons have iodine numbers above 900 mg/g, making them suitable for demanding applications like water purification and air filtration.

– Application-Specific Needs: Depending on the industry, a higher iodine number might be required. For example, pharmaceutical and food industries may prioritize higher iodine numbers to ensure maximum adsorption of harmful substances.

2. Particle Size – Granular or Powdered?

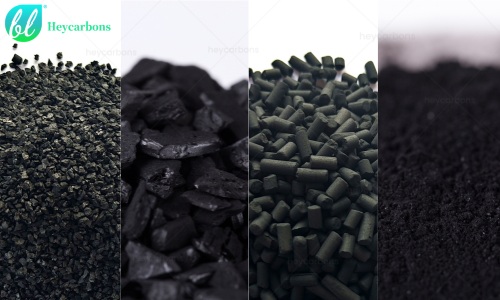

Another essential specification is particle size, which determines the speed and efficiency of the filtration process. Acid washed activated carbon is available in various forms, including granular activated carbon (GAC) and powdered activated carbon (PAC), each suited for different applications.

– Granular Activated Carbon (GAC): GAC has larger particle sizes and is typically used in systems where slower filtration is acceptable. It is ideal for continuous water treatment in municipal plants or industrial applications where the carbon needs to be retained within a filtration bed.

– Powdered Activated Carbon (PAC): PAC, on the other hand, has much finer particles and is often used in batch processes or when faster adsorption is required. PAC is commonly used in short-term water treatment solutions, such as in municipal emergency treatments or in industries where rapid decontamination is necessary.

Selecting the right particle size for your application can greatly impact the effectiveness and operational efficiency of your filtration system.

3. Hardness and Durability – Ensuring Longevity

The hardness of acid washed activated carbon is an important specification for ensuring the carbon’s durability during use. Hardness is especially critical in applications where the carbon is subject to high-pressure conditions, frequent backwashing, or long operational periods, such as in industrial water treatment systems.

– High Hardness Levels: Acid washed activated carbon typically has a hardness rating of 98% or higher, ensuring that the carbon can withstand physical wear and tear without breaking apart. This property is especially important for granular carbon, which needs to retain its structure during backwashing.

– Extended Lifespan: Hardness directly correlates with the operational lifespan of the carbon. Harder carbon is more resistant to abrasion, which reduces the need for frequent replacements and contributes to cost-effectiveness in long-term use.

4. Ash Content – The Importance of Purity

The ash content in activated carbon refers to the inorganic residue left after the carbonization process. Lower ash content is desirable because it reduces the amount of impurities that can interfere with adsorption processes. Acid washed activated carbon typically has a much lower ash content compared to non-acid washed variants.

– Reduced Ash Content: Acid washed carbon often contains less than 1% ash, compared to over 5% in non-acid washed alternatives. Lower ash content ensures that the carbon is more efficient in removing organic and inorganic impurities from water or air.

– Improved Filtration Efficiency: By reducing ash content, acid washed carbon minimizes the risk of clogging and improves the overall efficiency of the filtration system. This is especially beneficial in high-purity applications like pharmaceuticals and electronics.

5. Moisture Content – Maintaining Adsorption Efficiency

Moisture content is another factor to consider when selecting acid washed activated carbon. While all activated carbon contains some moisture, lower moisture content ensures that more of the carbon’s surface area is available for adsorption.

– Optimal Moisture Levels: High-quality acid washed activated carbon typically has a moisture content below 5%, allowing for maximum adsorption capacity. This is especially important in applications where the carbon needs to function in humid environments or when filtering large volumes of water.

– Prolonged Operational Efficiency: Low moisture content helps prevent the carbon from becoming saturated too quickly, thereby extending its operational life and reducing the frequency of replacements.

Conclusion: Selecting the Right Acid Washed Activated Carbon for Your Application

When choosing acid washed activated carbon, considering factors like iodine number, particle size, hardness, ash content, and moisture levels will help you select the right product for your specific application. Whether you’re using it for water purification, air filtration, or industrial processes, understanding these technical specifications is crucial for optimizing performance and ensuring long-term efficiency.

6.Environmental Impact – How Acid Washed Activated Carbon Contributes to Sustainability

As industries and consumers alike move towards more sustainable practices, the role of acid washed activated carbon in reducing environmental impact has become increasingly important. Acid washed activated carbon is not only effective in water and air purification, but it also plays a significant role in improving the sustainability of industrial processes. This part will explore the environmental benefits of using acid washed activated carbon and its growing relevance in eco-friendly industrial solutions.

1. Reducing Harmful Contaminants in Water

One of the most important environmental benefits of acid washed activated carbon is its ability to remove harmful contaminants from water sources. Water pollution is a critical global issue, and by using acid washed activated carbon in treatment plants and filtration systems, industries can significantly reduce the presence of dangerous pollutants such as heavy metals, volatile organic compounds (VOCs), and chlorine.

– Reduction of Heavy Metals: Acid washed activated carbon is highly effective at adsorbing heavy metals like lead, mercury, and arsenic from water supplies. These toxic substances can cause long-term damage to both ecosystems and human health if left untreated.

– Protection of Aquatic Ecosystems: By removing harmful chemicals from industrial discharge, acid washed carbon helps protect aquatic life and promotes healthier ecosystems. Many industries that use large quantities of water, such as textiles, mining, and chemical manufacturing, rely on this carbon to prevent contamination of nearby rivers, lakes, and oceans.

2. Improving Air Quality in Industrial Processes

Acid washed activated carbon is also widely used in air filtration systems, where it helps reduce emissions of harmful gases and volatile organic compounds. In industrial settings, air pollution can have a devastating impact on both local communities and the environment. The ability of acid washed carbon to adsorb airborne contaminants makes it an essential tool in reducing industrial emissions.

– VOC Removal: Acid washed activated carbon is particularly effective at capturing VOCs, which are emitted from industrial processes such as painting, fuel combustion, and chemical production. These compounds are known to contribute to air pollution and can cause respiratory problems for humans as well as damage the ozone layer.

– Reduction of Greenhouse Gases: In some industries, acid washed carbon is used in emissions control systems to reduce greenhouse gases like methane and carbon dioxide. By improving the filtration of these gases, industries can reduce their overall carbon footprint and comply with environmental regulations.

3. Supporting Sustainable Manufacturing Practices

The production and use of acid washed activated carbon are aligned with sustainable manufacturing practices, contributing to a circular economy. Activated carbon itself is often made from renewable raw materials such as coconut shells, which are a byproduct of the coconut industry, making it a sustainable and eco-friendly resource. Furthermore, acid washed carbon can be recycled and reactivated, extending its lifespan and reducing waste.

– Renewable Raw Materials: Many manufacturers produce activated carbon from renewable sources like coconut shells and wood. This minimizes reliance on non-renewable resources and helps reduce deforestation and other environmental impacts.

– Reactivation and Recycling: Once activated carbon becomes saturated with contaminants, it can often be reactivated through a high-temperature process that restores its adsorptive properties. This reactivation reduces the need for new carbon and helps minimize industrial waste.

4. Reducing Waste in Industrial Processes

Acid washed activated carbon helps industries reduce waste and enhance the efficiency of purification systems. In industries such as oil and gas, food and beverage, and pharmaceuticals, the use of acid washed carbon leads to less frequent filter changes and longer system operational times, thereby minimizing the waste generated by these industries.

– Extended Filter Lifespan: The improved hardness and adsorption capacity of acid washed carbon mean that it requires fewer replacements compared to non-acid washed alternatives. This reduces the overall waste generated during filtration processes, making the system more sustainable.

– Lower Chemical Use: By efficiently adsorbing a wide range of contaminants, acid washed activated carbon reduces the need for additional chemicals in water and air purification processes. This further minimizes the environmental impact of industrial filtration systems.

5. Compliance with Environmental Regulations

Many industries are subject to stringent environmental regulations, particularly in terms of wastewater discharge and air emissions. Acid washed activated carbon helps companies meet these regulations by providing an effective, environmentally friendly solution for reducing contaminants in both water and air.

– Water Quality Standards: Acid washed activated carbon enables industries to comply with water quality regulations by removing harmful contaminants before they are discharged into natural water bodies. This helps companies avoid legal penalties and contributes to broader environmental conservation efforts.

– Emissions Control: In the air filtration sector, the use of activated carbon in emissions control systems helps industries meet national and international standards for reducing airborne pollutants and greenhouse gases.

Conclusion: A Sustainable Future with Acid Washed Activated Carbon

Acid washed activated carbon plays a vital role in promoting environmental sustainability across a wide range of industries. By reducing water and air pollution, supporting renewable raw material use, and extending the lifespan of filtration systems, this versatile material helps industries minimize their environmental impact while maintaining efficiency.

As industries continue to adopt more sustainable practices, the demand for environmentally friendly solutions like acid washed activated carbon will only increase. For businesses seeking to align with sustainability goals and reduce their carbon footprint, investing in acid washed activated carbon is a practical and responsible choice.

7.FAQs About Acid Washed Activated Carbon

Acid washed activated carbon is widely used across industries, but people often have questions about its functionality, applications, and benefits. In this section, we’ll cover some of the most frequently asked questions (FAQs) about acid washed activated carbon to provide clarity on its uses and advantages.

1. What is Acid Washed Activated Carbon?

Acid washed activated carbon is a specialized type of activated carbon that undergoes an additional treatment with acid (typically hydrochloric acid) to remove impurities such as heavy metals, inorganic salts, and ash content. This washing process results in a cleaner, more efficient carbon that can better adsorb contaminants from water and air.

The primary advantage of acid washing is the removal of unwanted elements that could interfere with the carbon’s adsorption capabilities, particularly in sensitive applications like pharmaceutical water treatment or food production.

2. How Does Acid Washed Activated Carbon Differ From Non-Acid Washed Carbon?

The key difference between acid washed and non-acid washed activated carbon lies in purity and performance. Acid washed carbon has:

– Lower ash content: Ash is a residue left behind after the carbonization process, which can block the pores of activated carbon and reduce its effectiveness. Acid washed carbon has a lower ash content, generally below 1%, compared to 5% or higher in non-acid washed carbon.

– Lower heavy metal content: The acid washing process removes trace metals like iron and magnesium, making acid washed carbon better suited for applications where purity is critical, such as in dialysis or electronics manufacturing.

– Neutral pH: Acid washing adjusts the pH of the carbon to make it more compatible with certain applications, especially water purification. Non-acid washed carbon can have a higher pH, making it unsuitable for systems requiring neutral water conditions.

3. What Are the Key Applications of Acid Washed Activated Carbon?

Acid washed activated carbon is used in a wide variety of industries due to its high purity and excellent adsorption properties. Key applications include:

– Water Treatment: Acid washed carbon is used to purify water by removing chlorine, chloramine, organic compounds, and heavy metals.

– Food and Beverage Production: It is used in breweries, distilleries, and soft drink manufacturing to improve the quality of water and remove unwanted tastes and odors.

– Pharmaceuticals: In dialysis and other medical treatments, acid washed activated carbon ensures the purity of water used in sensitive medical processes.

– Air Purification: It captures volatile organic compounds (VOCs) and other airborne pollutants, improving air quality in industrial settings.

4. Why Is Acid Washed Activated Carbon Preferred for Water Purification?

Acid washed activated carbon is ideal for water purification because of its enhanced adsorption capacity, reduced ash content, and ability to remove specific contaminants like chlorine, VOCs, and heavy metals. These properties make it especially effective in sensitive applications where water purity is critical, such as in reverse osmosis systems, dialysis, and municipal water treatment.

By removing impurities through acid washing, the carbon ensures that the water remains clean, odorless, and free from harmful chemicals, making it a popular choice in both large-scale water treatment plants and residential filtration systems.

5. Can Acid Washed Activated Carbon Be Recycled or Reactivated?

Yes, acid washed activated carbon can often be reactivated through thermal processes. Reactivation involves heating the carbon to a high temperature in an oxygen-limited environment, which restores its adsorption properties by removing the contaminants that have built up on its surface.

This ability to recycle and reactivate acid washed carbon makes it an environmentally friendly option, as it extends the carbon’s useful life and reduces the need for new raw materials.

6. What Factors Should Be Considered When Choosing Acid Washed Activated Carbon?

When selecting the right acid washed activated carbon for your application, consider the following factors:

– Iodine Number: A measure of the carbon’s adsorption capacity. Higher iodine numbers indicate greater effectiveness in adsorbing small organic molecules.

– Particle Size: Choose between granular activated carbon (GAC) and powdered activated carbon (PAC) based on the application. GAC is typically used for continuous filtration, while PAC is better for fast adsorption in batch processes.

– Hardness: Harder carbon lasts longer and withstands physical stress during backwashing or extended use.

– Ash Content: Lower ash content improves the purity of the carbon and enhances its filtration efficiency, especially in sensitive applications.

Conclusion: Addressing Your Questions on Acid Washed Activated Carbon

Acid washed activated carbon is a highly versatile material that plays a vital role in a wide range of industries. Its superior adsorption capabilities, enhanced purity, and reusability make it a preferred choice for applications requiring high levels of cleanliness and efficiency. From water and air purification to food production and pharmaceuticals, acid washed activated carbon continues to demonstrate its value across the board.

8.Conclusion – The Future of Acid Washed Activated Carbon in Industry

Acid washed activated carbon has proven itself as an indispensable material across multiple industries, offering superior purification, filtration, and adsorption capabilities. As environmental concerns and regulatory standards continue to rise, this advanced form of activated carbon will only become more crucial in meeting industrial demands for clean water, air, and sustainable production methods.

In this final section, we’ll explore the future of acid washed activated carbon in industry and the emerging trends that will shape its ongoing evolution.

1. Increasing Demand for Water Purification Solutions

Water scarcity and contamination are growing global challenges, making efficient water treatment systems more important than ever. Acid washed activated carbon plays a pivotal role in addressing these concerns due to its ability to remove contaminants like chlorine, volatile organic compounds (VOCs), and heavy metals.

– Future Outlook: As both developed and developing nations invest in improving water infrastructure, acid washed activated carbon will remain a preferred solution in municipal water treatment plants, reverse osmosis systems, and residential filtration devices. Its ability to offer high levels of purity makes it ideal for ensuring clean drinking water for communities worldwide.

2. Expanding Role in Environmental Protection

With increasing environmental regulations and a global push for more sustainable practices, acid washed activated carbon is becoming a key component in emissions control and pollution reduction systems. Its ability to adsorb harmful gases and chemicals from industrial exhaust and wastewater makes it a valuable tool for reducing environmental impact.

– Emerging Applications: In industries like oil and gas, chemical production, and pharmaceuticals, the demand for activated carbon to reduce air pollution and treat industrial discharge is growing rapidly. Moreover, acid washed activated carbon’s ability to be reactivated and reused adds to its sustainability, making it a cost-effective and eco-friendly option for businesses.

3. Technological Innovations in Activated Carbon Production

As technology advances, so do the methods for producing activated carbon. Manufacturers are continually seeking ways to improve the performance, efficiency, and sustainability of their products. The future of acid washed activated carbon will likely involve innovations in material sourcing, production processes, and customization for specific applications.

– Biobased and Renewable Materials: One of the significant trends is the increased use of renewable raw materials like coconut shells, wood, and other biowastes in the production of activated carbon. This shift reduces reliance on non-renewable resources and further enhances the environmental benefits of using activated carbon in industrial applications.

– Enhanced Customization: Industries are also seeking more specialized forms of activated carbon to meet unique filtration and adsorption challenges. In the coming years, we may see more customized variations of acid washed activated carbon designed for specific uses, such as high-capacity air filtration or ultra-pure water treatment for electronics manufacturing.

4. Sustainability and Circular Economy

As industries worldwide strive to reduce their environmental footprints, sustainable filtration solutions are becoming a priority. Acid washed activated carbon, due to its ability to be recycled and reactivated, fits well into the circular economy model, which emphasizes the reuse and recycling of materials to minimize waste.

– Reactivation and Longevity: Many industries that use large amounts of activated carbon, such as water treatment plants, food and beverage producers, and chemical manufacturers, are beginning to adopt reactivation processes that allow them to reuse their activated carbon multiple times. This not only reduces costs but also lowers the environmental impact by minimizing the need for new raw materials.

Conclusion: A Bright Future for Acid Washed Activated Carbon

The future of acid washed activated carbon is bright, as its superior purification capabilities, sustainability, and adaptability make it indispensable in a wide array of industries. Whether used for clean water, purer air, or sustainable manufacturing practices, this versatile material will continue to play a critical role in meeting the world’s growing environmental and industrial challenges.

As industries shift towards greener, more sustainable technologies, acid washed activated carbon is poised to remain a central component of these solutions, driving innovation and environmental responsibility forward.

9.Final Thoughts on the Versatility and Importance of Acid Washed Activated Carbon

As we conclude this comprehensive exploration of acid washed activated carbon, it’s clear that this highly specialized material plays an essential role across multiple industries. From water and air purification to applications in the pharmaceutical, food, and electronics sectors, acid washed activated carbon is recognized for its superior filtration, high adsorption capacity, and environmentally friendly attributes. In this final section, we’ll summarize the key takeaways and explore the ongoing importance of this material in modern industrial processes.

1. Superior Filtration Across Multiple Industries

Acid washed activated carbon stands out for its ability to efficiently filter and purify substances, removing contaminants that are harmful to both humans and the environment. Whether it’s heavy metals in water or volatile organic compounds (VOCs) in air, this material has proven to be a reliable solution for industries with strict cleanliness standards.

– Water Purification: Acid washed activated carbon removes harmful substances like chlorine, chloramine, heavy metals, and organic pollutants, ensuring that the water used in municipal and industrial settings meets high purity standards.

– Air Purification: Industries like manufacturing, chemical processing, and energy production rely on this material to reduce emissions, including harmful gases and organic compounds.

2. Sustainability and Environmental Impact

As environmental regulations become more stringent, industries are seeking materials that not only perform efficiently but also contribute to sustainable operations. Acid washed activated carbon fits into this need for eco-friendly solutions by being recyclable, reactivatable, and made from renewable resources like coconut shells and wood.

– Circular Economy: The ability to reactivate and reuse acid washed carbon significantly extends its life cycle, reducing the demand for new raw materials and lowering the overall environmental footprint of industries that use it.

– Reduction of Industrial Waste: By improving the efficiency of filtration systems and requiring fewer replacements, acid washed activated carbon minimizes the waste generated during water and air purification processes.

3. Customization and Technological Innovation

One of the most exciting developments in the field of activated carbon is the potential for customization. As industries face increasingly complex filtration challenges, manufacturers are developing more specialized forms of acid washed activated carbon tailored to specific applications.

– Technological Advancements: Future innovations in the production process may include even more efficient methods of acid washing and carbon activation, improving adsorption rates and further lowering ash content.

– Application-Specific Solutions: From pharmaceutical-grade carbon to carbon used in advanced semiconductor manufacturing, the future will see an increasing demand for highly customized carbon solutions to meet specific industry needs.

4. Industry Applications Will Continue to Grow

As new environmental challenges emerge and regulations become more comprehensive, the demand for acid washed activated carbon will continue to rise. This material offers a versatile, eco-friendly solution for industries looking to improve their environmental impact while maintaining high levels of efficiency.

– Future Expansion: In addition to its current uses, acid washed activated carbon is poised to play a critical role in emerging fields such as renewable energy, sustainable agriculture, and biotechnology.

Conclusion: A Bright Future for Acid Washed Activated Carbon

The versatility, effectiveness, and environmental benefits of acid washed activated carbon ensure that it will remain a cornerstone of modern industrial processes for years to come. Its applications in water purification, air filtration, and sustainable manufacturing are only set to grow as industries look for ways to meet increasing regulatory demands and reduce their environmental footprints.

10.How to Implement Acid Washed Activated Carbon in Your Industry

Now that we’ve covered the advantages and applications of acid washed activated carbon in depth, it’s time to focus on how industries can effectively implement this powerful material into their filtration and purification processes. Whether you’re in the food and beverage industry, pharmaceuticals, or water treatment, choosing the right activated carbon solution and integrating it into your workflow is essential for maximizing efficiency, cost-effectiveness, and sustainability.

1. Assess Your Industry-Specific Needs

Before implementing acid washed activated carbon, it’s crucial to evaluate the specific needs of your industry. Different industries require varying levels of filtration, adsorption capabilities, and regulatory compliance. For example:

– Food and Beverage: In this sector, the focus is on removing organic compounds and chlorine from water, ensuring that no unwanted flavors or odors are introduced during production. The choice of activated carbon should meet food safety standards and provide the purity required for beverage production.

– Pharmaceuticals: For medical-grade applications, such as in dialysis or water used for medication manufacturing, the highest levels of purity are essential. Acid washed activated carbon used in these environments must meet strict regulatory standards, including compliance with guidelines from the U.S. Food and Drug Administration (FDA).

– Water Treatment: Municipal water treatment plants must consider the volume of water being filtered and the specific contaminants that need to be removed, such as chlorine, heavy metals, or organic pollutants. The correct grade of activated carbon ensures that filtration systems meet health and safety regulations.

2. Choose the Right Type of Acid Washed Activated Carbon

Once you’ve determined your industry requirements, the next step is selecting the correct type of acid washed activated carbon. As discussed in previous sections, there are multiple forms of activated carbon available, including:

– Granular Activated Carbon (GAC): Best for continuous filtration systems where water or air flows through a bed of activated carbon, such as in water treatment plants or air filtration systems.

– Powdered Activated Carbon (PAC): Ideal for batch processing and applications where rapid filtration is required, such as emergency water treatment or short-term industrial needs.

Your choice will depend on factors such as system flow rate, contaminant levels, and whether the process is continuous or requires short-term adsorption.

3. Integrate Acid Washed Carbon into Your Filtration Systems

After selecting the appropriate type of acid washed activated carbon, it’s essential to integrate it seamlessly into your existing filtration systems. Here are a few steps to ensure smooth implementation:

– Evaluate System Compatibility: Ensure that your existing filtration systems are compatible with acid washed activated carbon. This might involve modifying filtration beds, upgrading water or air flow mechanisms, or installing new pre-filtration systems to prevent clogging.

– Proper Loading and Maintenance: Acid washed activated carbon must be loaded correctly to optimize its adsorption capacity. Regular maintenance and monitoring of the filtration system are crucial to prevent system overloads and ensure long-term efficiency.

– Monitor Contaminant Removal: Once implemented, continuously monitor the levels of contaminants removed by the activated carbon to ensure it’s working as expected. In high-volume applications, setting up automated monitoring systems can improve efficiency.

4. Regularly Reactivate or Replace Activated Carbon

The long-term effectiveness of acid washed activated carbon depends on whether it’s properly maintained and, when necessary, replaced or reactivated. Reactivation involves restoring the carbon’s adsorption capacity by heating it to remove the contaminants it has absorbed.

– Reactivation: Many industries can benefit from reactivating their acid washed activated carbon instead of replacing it. This reduces waste and costs, while extending the life of the carbon. This is particularly useful in large-scale water treatment plants.

– Replacement: In industries where reactivation is not feasible, ensure regular replacement of the activated carbon based on your system’s filtration load and contaminant levels. Regular monitoring helps determine when it’s time to refresh your carbon.

5. Ensure Regulatory Compliance

As industries become more heavily regulated, ensuring that your use of acid washed activated carbon complies with local and international standards is vital. Various industries, especially pharmaceuticals, food and beverage, and water treatment, are subject to strict regulations.

– Water Treatment: Compliance with environmental regulations such as the U.S. Environmental Protection Agency’s (EPA) standards or the European Union’s Water Framework Directive ensures that water being treated is safe for public use.

– Food and Beverage: For food-related industries, compliance with the FDA, European Food Safety Authority (EFSA), and other relevant bodies ensures the carbon used in water filtration does not introduce harmful substances into products.

Conclusion: Seamlessly Implementing Acid Washed Activated Carbon in Your Operations

Successfully implementing acid washed activated carbon in your industry requires a clear understanding of your specific needs, choosing the right type of carbon, integrating it into your filtration systems, and ensuring compliance with regulatory standards. By following these steps, industries can enhance their filtration processes, reduce contaminants more effectively, and improve the overall sustainability of their operations.

Whether you’re looking to purify water, clean the air, or meet stringent industry standards, acid washed activated carbon offers a versatile and reliable solution that can be customized to meet your unique demands.

11.Heycarbons’ quality control and advantages in the production of acid washed activated carbon:

First, please check out our acid washed activated carbon production quality control video:

- Softened water is mixed with an acid solution and passed into the pool through a pipe, which is inserted into a hole at the bottom of the pool.

- By controlling the concentration of the acid solution and the pickling time and temperature, the ash, metal ions and other impurities in the activated carbon are further removed.

- The activated carbon is first repeatedly pickled in this pool, and the number of pickling times is determined by the ash and heavy metal requirements.

- After acid washing, alkaline washing and repeated water washing are carried out in this container to ensure that there is no residue.

- The used water enters the water treatment system and is recycled after treatment.

- This is the drying workshop, where the activated carbon after water washing is finally transported here through a pipe for drying.

We use a segmented drying furnace, and the temperature of each section is different. Through temperature control at different stages, the moisture inside and outside the activated carbon is guaranteed to be the same.

- After acid washing, the activated carbon has very low ash content, whether it is internal ash or external ash. It can be seen that it is very clean.