Zeolite

About Zeolite

Zeolite is a natural aluminosilicate mineral with a three-dimensional crystal structure. Zeolite composition includes the elements aluminum, oxygen, silicon and alkali metals or alkaline earth metals.

Where is zeolite found? Zeolite is mainly found from the cracks or amygdala of volcanic rocks, or in pyroclastic sedimentary rocks and hot spring deposits. Weichang County, Hebei Province is one of the areas with the highest zeolite reserves discovered in China, with zeolite reserves of more than 2 billion tons.

Key Figures of Zeolite Filter

2 billion tons

80

Types of Zeolite Filtration

There are many types of natural zeolites. According to the different metal ion contents, zeolite can be divided into clinoptilolite, mordenite, sodium zeolite, calcium zeolite, etc. According to the production method, there are modified zeolites soaked in reagents and activated zeolites.

Zeolite usually has strong adsorption properties, especially for metal ions and organic substances, and is widely used in water treatment, environmental protection, agricultural improvement, and as a catalyst. Especially in the field of water treatment, the filtration effect is better when zeolite is used with activated carbon during the water filtration process.

You will get a quote in 24 hours

You will get a quote in 24 hours

Two Forms of Zeolite Filter Media

Zeolite granule: It’s mainly produced by vibrating crushers, the raw ore is crushed and sieved through screens to obtain different particle sizes. Heycarbons mainly produces granular zeolite. The regular mesh sizes of the products Heycarbons sells are: 1-2, 2-4, 3-5, 5-8, 6-8, 1-3, 2-5. When the granules are too large or too small, the price will be more expensive. This is because small granules have more dust and large granules have a low discharge rate.

Zeolite powder: It’s mainly raymond mill, usually the remaining tailings after granules crushing are used for grinding. Heycarbons sells zeolite granules, of course we also sell zeolite powder. The regular mesh sizes of powdered zeolite are 70, 100, 140, 180 and 200.

Physical and Chemical Properties of Zeolite Water Filter Media

High ion exchange performance

High adsorption performance

Good catalytic performance

Thermal stability

Resistance to aggressive media

- Resistant to abrasion

Specification of Heycarbons Zeolite for Water Filtration

People often use zeolite granular for water filtration. The following is the parameter information of natural heycarbons zeolite filter media for water treatment. Heycarbons can also provide activated zeolite according to clients’ requirements.

| Item | Data | Item | Data | Item | Data |

|---|---|---|---|---|---|

| Specific Gravity | 2.16g/cm3 | SiO2 | 68-70% | Moisture | ≤2.0% |

| Volume Weight | 1.35g/cm3 | AI2O3 | 13-14% | NaO | 0.6-1.2% |

| Wear Rate | ≤0.8% | Fe2O3 | 1-1.8% | Mud Content | ≤1.0% |

| Crushing Rate | ≤1.0% | CaO | 1.8-2.2% | K2O | 1.6-3.9% |

| Porosity | ≥56% | MgO | 0.9-1.4% | Common size | 1-2, 2-4mm |

| Testing standard: CJ/T43-2005 | |||||

Heycarbons Zeolite Production Process

Processing Technology and Classification of Modified Zeolite

Modified zeolite is divided into reagent soaking and activation according to different modification methods. The performance of zeolite is improved by different treatment methods to meet different needs. The following is a detailed introduction to these two zeolite modification methods:

Modified Zeolite Soaked in Pharmaceutical Reagent

The production of modified zeolite soaked in reagents is to soak the zeolite in a solution containing a specific reagent (usually a metal salt solution or a chemical reagent). After soaking for a certain period of time, the reagent exchanges or reacts with the metal ions on the surface or in the pores of the zeolite, causing the ion exchange capacity, acidity or pore structure of the zeolite to change, thereby improving its performance.

Common reagents include metal ions (such as sodium, calcium, titanium, aluminum, etc.), acids, alkalis, solvents, etc. Different modification solutions should be used for modification according to different treatment objects.

The existing application types of activated modifized zeolite are divided into: ammonia nitrogen removal, iron and manganese removal, heavy metal removal, fluorine removal, and arsenic removal activated zeolite.

If you need modified zeolite, please contact Heycarbons and tell us your application requirements. Heycarbons will recommend the right zeolite for you.

You will get a quote in 24 hours

Activated Zeolite

Activated zeolite includes calcined zeolite and steam activated zeolite. The production of activated zeolite is to enhance the performance of zeolite through high temperature forging and steam activation treatment.

Calcined Zeolite

The calcined zeolite is fired in traditional earth kilns. The main function is to calcine and purify, reduce impurities and crystal water inside the ore, and improve the pore structure and thermal stability of the zeolite. The activated zeolite obtained after high-temperature calcination is widely used in catalytic reactions (such as petrochemical catalytic cracking), gas adsorption (such as air purification) and other fields.

Steam Activated Zeolite

People put the dried zeolite into steam treatment equipment and expose it to steam at a high temperature of 700°C to 1000°C. Steam can penetrate the pores of zeolite, remove internal impurities and moisture, improve the purity of zeolite. And it can also help expand the pores, enhance catalytic ability and adsorption capacity, and can be repeatedly regenerated and used.

Steam activated zeolite has a special pore structure and a large specific surface area, and has the characteristics of high mechanical strength, good adsorption capacity, strong ion exchange, and fast catalytic speed.

According to experiments, the ammonia nitrogen adsorption rate can reach more than 98%, while the ammonia nitrogen adsorption rate of general natural zeolite is between 50-90%. The experiment proves that the adsorption performance is stronger than that of natural zeolite, and the ion exchange performance is also better.

It can not only remove turbidity, color, and odor in water, but also has adsorption and exchange effects on harmful heavy metals in water such as iron, manganese, chromium, cadmium, nickel, zinc ions and organic matter: phenol, phosphate ions and other substances.

It is also beneficial to remove various micro-pollutants in water, and the water extract does not contain toxic substances. Therefore, activated zeolite is a new ideal filter material for industrial water supply, wastewater treatment and tap water filtration.

You will get a quote in 24 hours

You will get a quote in 24 hours

Application of Heycarbons Zeolite Purification

What is zeolite used for? The high surface area, high ion exchange capacity, high mechanical strength, fast catalytic rate, and strong hydration/rehydration and adsorption capabilities of natural clinoptilolite make it an excellent molecular sieve valued in a wide range of end-use applications from animal feed to water purification.

Use of Zeolite in Water Treatment

Especially in zeolite for water filtration, one of the great advantages of zeolite is that it can be used for a wide range of filtration needs, for both industrial and non-industrial purposes, making it a versatile water filtration medium. Zeolite has good wear resistance and is almost unaffected by pollutants, which can effectively remove pollutants from water sources and be used for water filtration and wastewater treatment to reduce harm to the environment.

What does zeolite filter out of water?

People also ask what zeolite filters out of water. Modified zeolite can remove a variety of pollutants in water, including ammonia nitrogen, fluorine, iron, manganese, heavy metals, arsenic and other substances. The following table shows you the basic properties of heycarbons zeolite products. Zeolite can be used in many fields such as soft water, wastewater treatment, and environmental purification.

Heycarb Team recommends using zeolite with activated carbon and anthracite. Using anthracite, activated carbon and zeolite filter media together can be for better filtration effect and wider application areas.

| Mainly remove impurities | Amount of impurities removed per kilogram of filter media | Mainly remove impurities | Amount of impurities removed per kilogram of filter media |

|---|---|---|---|

| F | 1000mg | NH3 | 40000mg |

| Fe | 3500mg | As | 2000mg |

| Mn | 2500-3000mg | Heavy mental | 240-3000mg |

You will get a quote in 24 hours

Related Use of Zeolite

Water purification

For the use of zeolite water treatment, zeolite can remove ammonia nitrogen, iron and manganese, heavy metals, arsenic and fluoride to purify water quality.

Size: 1-2mm, 2-4mm

You will get a quote in 24 hours

Aquaculture

Zeolite can be used for water purification, fish pond bottom paving and zeolite sand for pool. And it can also be used for hatching grouper, sea cucumber, shrimp and crab, etc.

You will get a quote in 24 hours

Undercurrent wetland

People can use zeolite for artificial wetlands, park backfill and permeable materials to effectively filter and remove pollutants such as ammonia nitrogen, heavy metals, and phosphorus from sewage.

Size: 8-16mm, 16-32mm, 32-65mm

You will get a quote in 24 hours

Gardening

People can use zeolite for gardening paving, mixing soil for succulents, flowers and other plants. And it can also be used as decoration for garden construction.

You will get a quote in 24 hours

Animal (livestock) feed

Zeolite powder contains a lot of trace elements and can be mixed evenly with the feed of cattle, sheep, livestock, fish, shrimp and crabs for feeding.

Size: 180-200mesh

You will get a quote in 24 hours

Soil improvement

After activation, zeolite can be used as a soil conditioner to improve soil quality, adjust pH value and biological properties, and help plant growth.

Size: 40-70mesh

You will get a quote in 24 hours

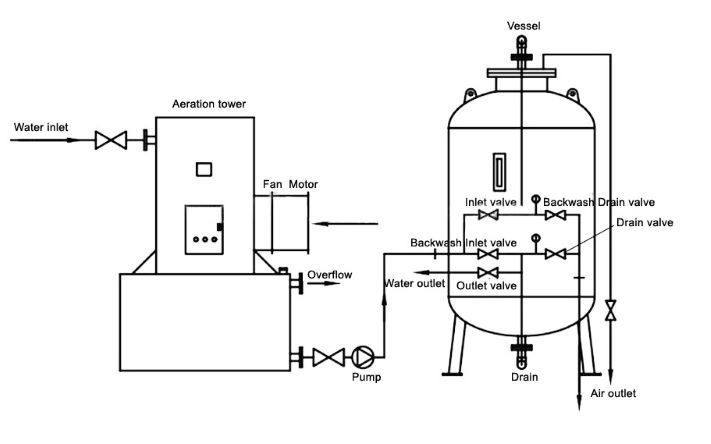

Flow Chart of Filter Media for Water Treatment

Anthracite/Manganese Sand/Medical Stone/Activated carbon for water treatment you may be interested in

Let’s Get in Touch

We’re open for any suggestion or just to have a chat

Contact with us

We will give you the help you need