1. Solvent Recovery Introduction

In modern industry, the concept of environmental protection and sustainable development is increasingly important.

Activated carbon solvent adsorption and recovery technology, as an efficient and environmentally friendly solution, can effectively reduce industrial waste and improve resource utilization.

Activated carbon plays an indispensable role in solvent recovery with its excellent adsorption properties.

2. Basic principle of solvent adsorption by activated carbon

The structural characteristics of activated carbon are its main advantage.

Activated carbon has a highly porous structure and a large specific surface area that can effectively capture and retain solvent molecules.

Its adsorption mechanism is mainly categorized into physical adsorption, which adsorbs molecules through van der Waals forces and electrostatic forces, and chemical adsorption, which forms stronger bonds through chemical reactions.

| adsorption mechanism | descriptive |

| physical adsorption | Weaker bonding through van der Waals force action |

| chemisorption | High adsorption energy due to strong bonding through chemical reaction |

3. Activated carbon solvent recovery methods: adsorption, condensation and membrane separation method

In activated carbon solvent recovery, adsorption, condensation and membrane separation are the three main technologies, each with its own unique advantages and application scenarios.

1. Adsorption

Adsorption utilizes the pore structure and high specific surface area of activated carbon to capture and retain solvent molecules.

| Adsorption type | descriptive | application scenario |

| physical adsorption | Van der Waals force adsorption, suitable for a variety of organic solvents | Commonly used in industrial waste gas and waste water treatment |

| chemisorption | Solvent molecules react chemically with the surface of activated carbon, resulting in a stronger bonding force | Efficient recovery of special solvents, e.g. benzene, alcohol solvents |

2. Condensation

Condensation is the process of converting gaseous solvents to liquid form by lowering the temperature to facilitate collection and recovery.

| Condensing method | descriptive | advantages and disadvantages |

| direct condensation | Condensation of solvents in gases directly through the cooling medium | Highly efficient and suitable for large-scale recycling |

| indirect condensation | Gas cooling through heat exchangers to reduce heat loss | Low energy loss, but high equipment cost |

3. Membrane separation

Membrane separation utilizes the properties of selective membrane materials to separate solvent molecules and other components with high efficiency and low energy consumption.

| Membrane Type | descriptive | Scope of Application |

| reverse osmosis membrane | Pressure-driven separation for recovery of water-soluble solvents | Water treatment and wastewater recycling |

| ultrafiltration membrane | Separates larger molecules, suitable for removing suspended solids and colloids | Food, beverage and pharmaceutical industries |

| nanofiltration membrane | Between reverse osmosis and ultrafiltration, suitable for the separation of small and medium molecules | Recovery of industrial solvents |

Adsorption, condensation and membrane separation each have different advantages and are suitable for different types of solvent recovery needs.

By combining these methods, companies can effectively improve the efficiency and economic benefits of solvent recovery. Choosing the right technology will help to realize the goal of sustainable development.

4. Common types of activated carbon solvent adsorption recovery

Common solvents suitable for activated carbon recovery include:

- benzene

- acetone

- wood spirit

- ethanol

These solvents are widely used in the petrochemical, pharmaceutical and chemical industries.

| fluids | Application Sectors | specificities |

| benzene | petrochemical industry | Efficient adsorption, easy recovery |

| acetone | pharmaceutic | Low boiling point for rapid recovery |

| wood spirit | metallurgy | Low price and wide range of applications |

5. Activated carbon solvent adsorption and recovery equipment and process flow

The main types of equipment for solvent recovery include fixed bed and fluidized bed adsorption units. Each type of equipment has its own unique principle of operation and areas of application.

Equipment types and processes:

- Fixed-bed adsorption equipment

- Working principle: The solvent passes through the fixed bed activated carbon layer and is adsorbed.

- Advantages: Suitable for handling large flows, easy to maneuver.

- Fluidized bed adsorption equipment

- Working Principle: Activated carbon particles are suspended in the airflow to increase the contact area.

- Advantages: Improved adsorption efficiency, suitable for treatment of highly concentrated solvents.

| Equipment type | Working Principle | Avantage |

| Fixed bed adsorption equipment | Solvent adsorption through fixed carbon bed | High traffic handling, easy to operate |

| Fluidized bed adsorption equipment | Suspension of carbon particles to increase contact area | Improvement of adsorption efficiency |

6. Economic and environmental benefits of activated carbon solvent recovery

Activated carbon solvent recovery not only reduces production costs and raw material waste, but also significantly reduces VOC emissions and meets environmental standards. Through effective recycling technology, enterprises can achieve higher resource utilization and economic benefits.

| Type of benefit | descriptive |

| economic benefit | Lower production costs and reduced raw material procurement expenses |

| Environmental benefits | Reduced VOC emissions and compliance with environmental regulations |

7. How to choose the right activated carbon for solvent recovery

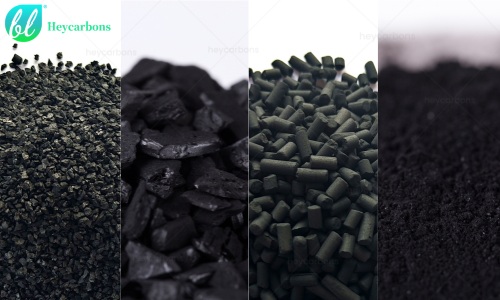

Choosing the right activated carbon is critical. Different types of activated carbon (e.g., coal-based and coconut shell-based) differ in their adsorption effectiveness. Factors to consider include pore size distribution, specific surface area and mechanical strength.

| Type of activated carbon | Pore size distribution | specific surface area | mechanical strength |

|---|---|---|---|

| Coal-based activated carbon | Large pores dominate | 600-1200 m²/g | comparatively strong |

| Coconut shell based activated carbon | Small and medium-sized pores dominate | 1000-1500 m²/g | weaker |

8. Practical application of activated carbon solvent recovery

The application of activated carbon has shown its superiority in several industries. For example, in the petrochemical industry, activated carbon can be used for benzene recovery; in the pharmaceutical industry, acetone can be efficiently recovered.

| sector | Solvent type | Application Cases |

| petrochemical industry | benzene | Benzene recovery system |

| Pharmaceutical industry | acetone | Acetone Recovery Process |

9. Regeneration and recycling of activated carbon

Regeneration technology of activated carbon is the key to enhance its utilization efficiency. Common regeneration methods include thermal regeneration and water washing regeneration. Regenerated activated carbon has significant improvement in adsorption performance and service life.

| Regeneration methods | descriptive |

| thermal regeneration | Removal of adsorbed solvents by heating |

| Washing and regeneration | Remove impurities by washing with water |

Learn more:

Maximizing Cost Efficiency: A Comprehensive Guide to Activated Carbon Regeneration Methods

10. The future development trend of activated carbon solvent adsorption and recovery

With the advancement of science and technology, the modification of activated carbon and the application of nanomaterials will drive the innovation of solvent recovery technology in the future. In addition, increasingly stringent environmental regulations will also promote the development of this technology.

| growing trend | descriptive |

| Activated Carbon Modification | Improved adsorption properties and enhanced affinity for specific solvents |

| Nanomaterials Applications | Combined with nanotechnology to improve the adsorption efficiency of activated carbon |

11. Conclusion

The importance of activated carbon in solvent adsorption and recovery cannot be overlooked.

Its economic and environmental benefits not only help companies achieve their solvent recovery goals, but also support sustainable development. Readers are advised to take a closer look at activated carbon technology or contact a service provider for an optimal solvent recovery solution.

12. Frequently Asked Questions (FAQ)

How does an activated carbon solvent recovery system work?

The system recovers solvents through adsorption, desorption and condensation steps for efficient recycling.

Which solvents are suitable for adsorption recovery with activated carbon?

Common ones include benzene, acetone, and methanol, depending on industry demand.

What is the cost of activated carbon solvent recovery?

Costs vary depending on the type of equipment, size and operating conditions and are usually assessed in detail.

Learn more: