Manufacture Process of Activated Carbon

- Introduction

- Wood Activated Carbon Chemical Production Process

- Coconut Shell Activated Carbon Production Process

- Manufacture of Steam Coal-based Activated Carbon

Contents

Chapter 1

Wood Activated Carbon Chemical Production Process

Advantages Wood Activated Carbon Chemical Activation

High methylene blue, good decolorization effect

Low ash content

PH can be adjusted

Low price

Wood Activated Carbon Chemical Activation by Phosphoric Acid Method

1.Advantages of activated carbon produced by phosphoric acid chemical method,

compared with activated carbon produced by steam physical method.

More controllable pore structure: Phosphoric acid chemistry can more effectively control the pore structure of activated carbon. By adjusting process parameters such as phosphoric acid concentration, impregnation ratio and carbonization temperature, a more precise pore size distribution and richer microporous structure can be obtained. This is particularly important for applications that require specific pore structures, such as adsorption of specific molecules or use as catalyst supports.

Higher production efficiency: The production process of phosphoric acid chemical method is usually carried out at a lower temperature. Compared with the high-temperature carbonization and activation steps required by steam physical method, it saves energy consumption, shortens production time and improves production efficiency. In addition, phosphoric acid as an activator can promote the dehydration, carbonization and activation of biomass materials, completing the entire production process in a shorter time.

Higher yield: Since the activation process of phosphoric acid chemical method can be carried out at a lower temperature and the loss of raw materials is less, the yield of activated carbon is relatively high. On the contrary, the steam physics method requires high temperature treatment, resulting in greater raw material consumption and lower yield.

Activated carbon has richer surface chemistry: Activated carbon produced by phosphoric acid chemistry generally has richer surface functional groups, such as carboxyl, hydroxyl and phosphate groups. These functional groups can enhance the adsorption capacity of activated carbon for certain pollutants (such as heavy metal ions, organic compounds), and can also improve its effectiveness in catalysis, deodorization and other applications.

Mild process conditions: The reaction conditions of the phosphoric acid chemical method are relatively mild, and the carbonization and activation process can usually be completed between 400-600°C, while the steam physical method requires activation at 700-900°C or even higher temperatures. Lower process temperatures not only reduce equipment requirements and energy consumption, but also reduce uneven carbonization and structural damage caused by high temperatures.

Environmental friendliness: Although the phosphoric acid chemical method requires the use of chemical reagents, phosphoric acid itself is a relatively environmentally friendly acidic activator and can be recycled, reducing environmental pollution. The steam physics method produces more gas emissions at high temperatures, which may have a certain impact on the environment.

To sum up, activated carbon produced by phosphoric acid chemical method has certain advantages in terms of pore structure control, production efficiency, yield, surface chemical characteristics, process conditions and environmental friendliness. Therefore, it may be better than steam physics in some specific applications. law is more applicable.

2. Preparation of raw and auxiliary materials.

In China, the main raw material for producing activated carbon by phosphoric acid method is sawdust, among which coniferous wood sawdust is superior to broadleaf wood sawdust, and fir sawdust is superior to pine sawdust. Fresh pine sawdust contains more rosin, which hinders the penetration of phosphoric acid molecules. Therefore, if pine sawdust is stored for a period of time, the volatile components in the rosin are naturally volatilized, decomposed and oxidized before use, it will be more conducive to the production of activated carbon.

The process requirements of sawdust raw materials are shown in Table 1-1.

surface1-1 Process requirements for sawdust

project | Process requirements |

variety | Fir sawdust, pine sawdust, various miscellaneous sawdust |

granularity | 0.425~ 3.35mm |

purity | Does not contain board skin, wood blocks, mud, sand and iron filings, etc. |

Moisture content | The relative moisture content is 15% ~ 20% |

2. Methods for preparation and activation of wood activated carbon

1.Production Process flow

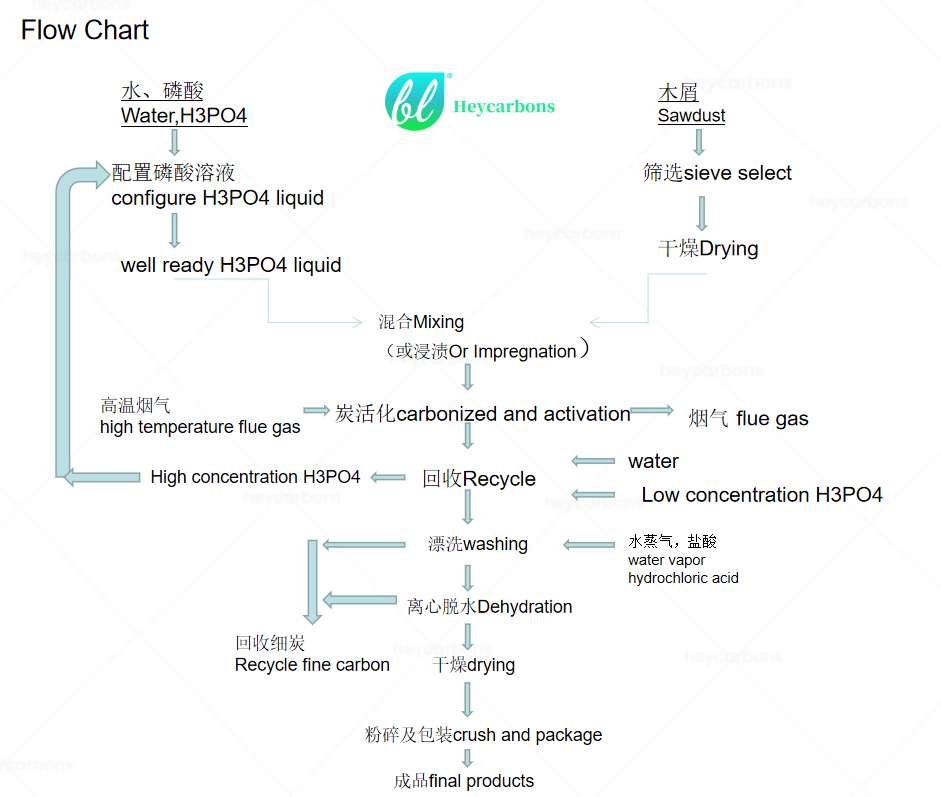

The process flow of continuous production of powdered activated carbon by phosphoric acid involves several key steps. The whole process usually includes sawdust screening, sawdust drying, phosphoric acid solution preparation, raw material and phosphoric acid mixing (or impregnation), carbonization and activation, phosphoric acid recovery, rinsing (including acid treatment and water washing), centrifugal dehydration, drying and grinding. In addition, there is a special exhaust gas treatment system for recovering phosphoric acid and sulfuric acid in flue gas to minimize pollution to the environment.

In order to ensure that the operation of each link can be carried out stably and efficiently, the control of key parameters is very important. The following are the key parameters of the process steps and main operations:

Process steps | Main Operations | Key Parameters |

Impregnation | Mix the raw materials with phosphoric acid | H₃PO₄ concentration: 40-60%, immersion time: 12-24 hours |

Carbonization and activation | High temperature carbonization and activation reaction | Temperature: 400-600°C, Time: 2-3 hours |

Cooling and washing | Cool to room temperature and wash with hot water | Washing water temperature: 80-90°C, washing times: 3-5 times |

2.Production Process operation

(1) Screening and drying of sawdust

In order to ensure the quality of the final product and the stability of the process operation, the sawdust needs to be strictly screened and dried. Usually, a vibrating screen or a drum screen is used to screen the sawdust, and sawdust particles with a particle size between 0.425 and 3.35 mm are selected.

Sawdust in this particle size range helps the smooth progress of subsequent processes and can effectively improve the quality of activated carbon. During the screening process, impurities such as board skin, iron filings, mud, sand and stones need to be removed to avoid these impurities from clogging in the subsequent impregnation and rinsing processes and increasing the equipment load, thereby affecting product quality.

(2) Preparation of phosphoric acid solution

The preparation of phosphoric acid solution is one of the key links that affect the process and product quality. Whether the concentration and preparation of phosphoric acid solution meet the process requirements is directly related to the ratio of raw materials to phosphoric acid.

Which has an important impact on the performance of the final product. Usually, a high-concentration industrial phosphoric acid solution of 85% (mass fraction) is used, which is diluted with water to the required concentration according to the process requirements to achieve the Baumé degree specified in the process.

The Baume degree of phosphoric acid solution is closely related to temperature. When the mass fraction of phosphoric acid solution is constant, the Baume degree of the solution will decrease accordingly as the temperature increases. Therefore, during operation, in order to ensure that the Baume degree of the solution meets the process requirements, the temperature of the solution must be indicated.

Understand the relationship between the Baume degree, density and mass fraction of the phosphoric acid solution, and the corresponding values of these parameters at different temperatures to ensure that the operator can accurately control the characteristics of the solution.

(3) Mixing (or impregnation)

The main purpose of mixing is to fully stir and knead the sawdust and phosphoric acid solution so that the two can be evenly mixed and the penetration of phosphoric acid molecules into the biological tissue of the sawdust can be accelerated. This process is usually carried out in a mixer, which is made of acid-resistant steel, has a semicircular trough shape, and is equipped with a pair of zigzag agitators inside. The design of the agitator ensures that the sawdust and phosphoric acid solution can fully contact during the mixing process to achieve a uniform impregnation effect.

In addition to using a mixer, other equipment can also achieve similar impregnation purposes. For example, equipment such as twin-screw augers and rotary kilns can also achieve ideal mixing and impregnation effects under certain conditions. The selection of these equipment is usually adjusted according to specific process requirements and production scale.

(4) Carbon activation process

Carbon activation is one of the key steps in the preparation of activated carbon, and the quality of activation directly affects the performance of the final product. Carbon activation is usually carried out in a rotary kiln, which is mainly divided into two types: internal heating and external heating. Japan mostly uses external heating rotary kilns, while China generally uses internal heating rotary kilns.

The main difference between the internal heating rotary kiln and the external heating rotary kiln is the contact method between the heat source and the material. In the external heating rotary kiln, the high-temperature airflow does not directly contact the material, but heats the material through the heat radiated from the furnace wall. This heating method can transfer heat more evenly, which is conducive to improving product quality, but it requires high heat resistance and corrosion resistance of the rotary kiln material. In contrast, the internal heating rotary kiln directly heats the material through the high-temperature flue gas flow, so that it heats up quickly and activates.

The structure of the commonly used internal heating rotary kiln in China is usually shown in Figure 2-3. This type of furnace is simple in design and relatively low in cost, suitable for large-scale industrial production, and is therefore widely used in China.

Wood-Based Activated Carbon Production Process

1. **Sawdust** → Sieve select → Drying

2. **Water, H3PO4** → Configure H3PO4 solution

3. **H3PO4 Solution** → Mixing or Impregnation

4. **Carbonization & Activation** → Flue gas emission | High concentration H3PO4 recycling

5. **Washing** → Recycle fine carbon | Water vapor & hydrochloric acid emission

6. **Centrifugal Dehydration**

7. **Drying**

8. **Crushing & Packaging**

9. **Final Product**

(5) Phosphoric acid recovery

During the activation process, a large amount of phosphoric acid and phosphoric acid polymers (such as pyrophosphoric acid, metaphosphoric acid, etc.) formed under high temperature conditions will remain in the activated carbon. According to measurements, the content of these substances can be as high as about 75%, so recycling these substances is crucial to reducing “acid consumption”.

At the same time, the process also requires post-treatment of the activated carbon to remove these phosphoric acid polymers and other impurities. The recovery operation of phosphoric acid is essentially an extraction process. Through specific operating conditions, phosphoric acid and its polymers are separated from the activated carbon and recycled.

Phosphoric acid is a non-volatile acid. When heated to 200~300℃, a dehydration reaction will occur to generate pyrophosphoric acid. The reaction is as follows:

2H3PO4 → H₄P₂O₇ + H₂O(Pyrophosphoric acid)

When the temperature rises further to above 300°C, phosphoric acid loses water and converts into tripolyphosphoric acid:

3H3PO4 → H5P3O10 + 2H₂O (Tripolyphosphoric acid)

If the temperature reaches white-hot, phosphoric acid loses water and turns into polymetaphosphoric acid:

4H3PO4 → (HPO3)4 + 4H₂O (Polymetaphosphoric acid)

Polymetaphosphoric acid will not decompose at high temperatures, but will only sublimate. Whether it is pyrophosphoric acid, tripolyphosphoric acid or polymetaphosphoric acid, it will be converted into orthophosphoric acid in water. In the preparation process of activated carbon, due to the low activation temperature (usually between 450~500°C), phosphoric acid will not volatilize and only exist in the form of pyrophosphoric acid, tripolyphosphoric acid or polymetaphosphoric acid. This means that during the activation process, phosphoric acid still exists stably and no volatilization loss occurs.

Therefore, the recycling operation usually adds phosphoric acid solutions of different concentrations to the recycling barrel containing the activated material, and separates the residual phosphoric acid and phosphoric acid polymers by adjusting the concentration of the solution and the soaking time. The recovered phosphoric acid solution can be reused in the impregnation and activation process after treatment, which effectively reduces the acid consumption in the production process and improves the resource utilization rate.

The phosphoric acid method is mainly used to make wood activated carbon, especially powdered activated carbon. It is widely used for food decolorization, fish protein purification,marine collagen decolorization, sugar, glucose, edible oil, vegetable oil, engine oil and sewage decolorization and purification.

Learn more:

Chapter 2

Coconut Shell Activated Carbon Production Process

Advantages of coconut shell activated carbon:

Micropores developed

Low ash,Purity

High hardness

Coconut shell activated carbon is widely used in environmental protection, medicine, chemical industry and other fields due to its excellent adsorption performance and high mechanical strength. Its production process usually includes key steps such as raw material selection, carbonization and activation, among which the activation process is the core link that determines its final performance. The activation methods are mainly divided into chemical method and physical method, and the process characteristics and application fields of each method are different. The following is a detailed production process of coconut shell activated carbon, with special emphasis on the activation process and the difference and application of its two main methods.

1. Raw material selection and pretreatment

Raw material selection: Select high-quality coconut shells and ensure that the shells are dry and free of impurities. Coconut shells are rich in fixed carbon and low in ash, making them ideal raw materials for producing high-quality activated carbon.

Washing and drying: Wash the coconut shells to remove dust and impurities on the surface, and then dry them in the sun or in a dryer to reduce the moisture content.

2. Carbonization

Low-temperature carbonization: Carbonize the dried coconut shells at a low temperature of 300°C to 500°C to remove volatile components and leave solid carbon. Carbonization is usually carried out in an oxygen-free or oxygen-deficient environment to prevent the material from being completely burned.

Carbonization product: The product after carbonization is called green charcoal or precursor, which still lacks sufficient pore structure and needs to be further activated.

3. Methods for preparation and activation of COCO activated carbon

Activation is the most critical step in the production of coconut shell activated carbon, which directly determines its adsorption performance. Activation methods are mainly divided into chemical activation and physical activation, each of which has its own unique mechanism and application field.

Chemical Activation

Chemical Reagent Treatment: The carbonized coconut shell is mixed with a chemical activator (such as potassium hydroxide KOH, phosphoric acid H₃PO₄ or zinc chloride ZnCl₂), and the chemical reagent is evenly distributed on the surface and inside of the material through impregnation.

Heating Activation: The impregnated material is heated at a high temperature of 500°C to 900°C. The chemical reagent reacts with the carbon at this temperature to form a rich and uniform pore structure.

Washing and Drying: After heating, it is washed with water to remove residual chemical reagents and by-products, and then dried to obtain the final activated carbon product.

Application Fields

The coconut shell activated carbon produced by chemical activation usually has a high specific surface area and a uniform microporous structure, which is suitable for fields requiring fine adsorption performance, such as medicine, food processing and gas purification.

Physical activation

Gas activation: The carbonized coconut shell material reacts with an activation gas (such as water vapor or carbon dioxide) at a high temperature of 700°C to 1000°C. The gas undergoes an oxidation reaction with the carbon to generate a large number of mesoporous and macroporous structures.

Cooling and collection: After activation, the activated carbon is cooled to room temperature and collected.

The following are some common physical activation methods:

(1) Activation by stewing furnace

This method loads the carbonized material (usually with a particle size of less than 0.1 mm) that has been acid-washed, washed and dried into an activation tank with air permeability, and then places it in a stewing furnace and passes the activation gas through for activation. Its characteristic is that the carbonized material is fixed, and the activation gas penetrates from the tank wall and contacts the carbonized material for activation reaction, which belongs to fixed bed operation. Stewing furnaces are available in two styles: flat top and arch top.

(2) Moving bed activation method

The moving bed activation method activates the raw materials by contacting the activation gas during intermittent or continuous movement. Compared with the fixed bed activation method, the effect is more uniform and the product quality is higher. The moving bed equipment is convenient for recycling the activated tail gas and has good energy-saving effect. Therefore, it is widely used in China in various forms. Common furnace forms include:

Multi-tube furnace: The material moves from top to bottom by its own gravity. It can produce granular activated carbon and crush the carbonized material to produce powdered activated carbon. The inner wall of the furnace is made of refractory bricks, the outer wall is ordinary red bricks, and there is an insulation layer between the inner and outer walls.

Multi-stage furnace: also known as rake furnace, because it has rake teeth inside to stir the carbon layer. This type of furnace is the mainstream activation furnace mode in Europe, America, Japan and other places. It has good activation quality and can produce various medium and high-grade activated carbon products.

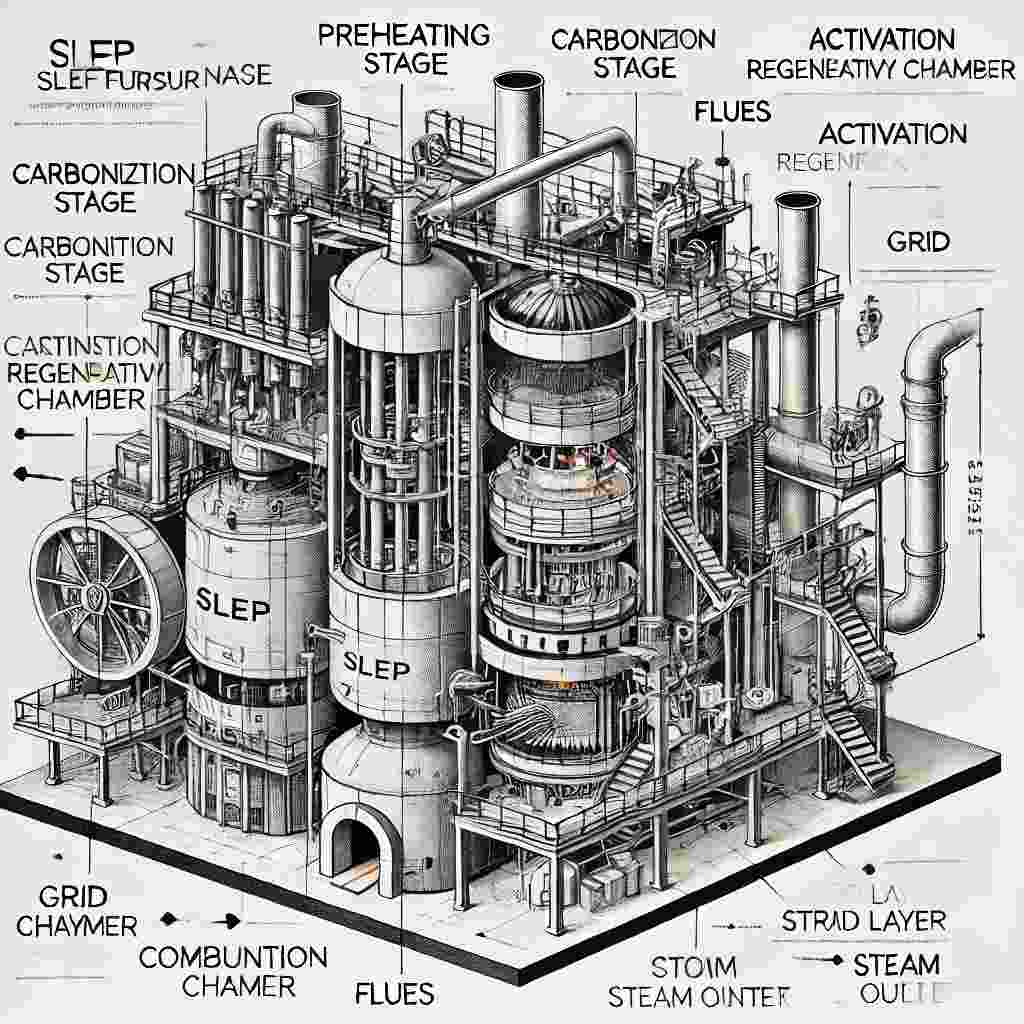

Slep furnace: Slep furnace (SLEP Furnace) was originally a French patent and was later introduced into my country by the Soviet Union. The furnace uses alternating water vapor and flue gas for activation. The raw materials are evenly mixed in the furnace, and the activation quality is good. It is suitable for the production of various medium and high-grade activated carbons. Its structure includes furnace body, heat storage chamber, water seal, discharger, air and steam pipe system, instrumentation, flue chimney and other parts.

Its structure is shown

(3) Rotary kiln activation method

The characteristic of the rotary kiln is that its furnace body will continue to rotate during the activation process, so the raw materials in the furnace are forced to turn over continuously during the rotation process. This mechanism effectively enhances the contact between gas and solid, thereby ensuring the uniformity of product quality. In addition, the rotary kiln overcomes the limitation of the Slep furnace that has a high requirement for the particle size range of raw materials.

The design of the rotary kiln includes two types: internal heating type and external heating type. The activation gas can be selected to use water vapor alone or a mixture of water vapor and flue gas for activation. This flexible design enables the rotary kiln to stably produce high-quality activated carbon products under various conditions.

Table 2-1 Comparison of production data between electric heated rotary kiln and Slep furnace

Furnace type | Electric Heating Rotary Kiln | Slep Furnace |

Activation rate/% | 63 | 38.12 |

Iodine adsorption value/ (mg/g) | 1100 | 1060 |

Methylene blue adsorption value/ (mL/0.1g) | 14 | 13 |

strength/% | 98 | 95 |

Coal consumption/(t/t) | 1 | 3.45 |

Power consumption/ (kWh/t) | 38401 | 100 |

As can be seen from Table 2-1, although the electric rotary furnace has obvious advantages in terms of activated carbon performance and activation yield, its high power consumption is a significant disadvantage. Therefore, in future research, efforts should be made to reduce energy consumption by making full use of the combustible exhaust gas generated during the activation process, thereby improving the overall economy of the electric rotary furnace.

Among them, the Slep furnace is commonly used for steam activation of coconut shell activated carbon.

Application areas

Physically activated coconut shell activated carbon usually has larger pore sizes and is suitable for applications that treat large amounts of adsorbate, such as water treatment, air purification, and industrial waste gas treatment.

4. Screening and grading

- Screening: The activated coconut shell activated carbon is screened through a screening machine and divided into different grades according to particle size. Common specifications include powdered, granular or columnar activated carbon.

- Grading: Activated carbon is graded and classified based on customer needs or application requirements to ensure that the product meets specific quality standards.

5. Quality inspection and packaging

- Quality inspection: The completed coconut shell activated carbon needs to undergo a series of quality inspections such as specific surface area, pore size distribution, adsorption performance, and mechanical strength to ensure product quality.

- Packaging: Packaging of qualified activated carbon, using moisture-proof and anti-pollution packaging materials to ensure the stability of the product during transportation and storage.

Summarize

The production process of coconut shell activated carbon covers multiple steps from raw material selection to final product packaging, and the activation process is the core link. Chemical activation is suitable for high-precision adsorption applications, such as medicine and food processing; physical activation is more suitable for large-scale environmental treatment, such as water treatment and air purification. Different activation methods determine the characteristics and application fields of activated carbon. Choosing the appropriate process will directly affect the performance and market value of activated carbon.

The main advantages of physical steam activated carbon:

1. **High product purity**:

The physical steam method uses high-temperature steam activation and usually does not require the introduction of chemical reagents. Therefore, the activated carbon produced has high purity and less surface residue. For some application scenarios that are sensitive to chemical residues, such as food, medicine, water treatment and other fields, this high-purity activated carbon is very important.

2. **No chemical pollution**:

The physical steam method does not use chemical activators, which avoids the chemical pollution problems that may exist in the chemical method. The production process is more environmentally friendly and suitable for industries with high requirements for environmental and product safety, such as drinking water purification and air purification.

3. **Stable pore structure**:

The pore structure of physical steam activated carbon is usually relatively stable, and the formation of pores mainly depends on the physical reaction between steam and carbonized products. This pore structure is not easy to collapse or change during use, and is suitable for occasions that require long-term stable adsorption performance.

4. **Suitable for large-scale production**:

The physical steam method is suitable for large-scale industrial production, with relatively mature processes, clear equipment requirements, easy standardization of operation control, and low production costs. For industrial applications that require large amounts of activated carbon, the physical steam method can provide stable and efficient production capacity.

5. **Wide range of applications**:

Because the activated carbon produced by the physical steam method has a wide pore size distribution, ranging from micropores to mesopores, it is suitable for a variety of adsorption applications, including gas phase adsorption (such as removal of volatile organic compounds) and liquid phase adsorption (such as removal of organic matter in water treatment).

7. **Simple process and easy to control**:

The process flow of the physical steam method is relatively simple, mainly involving two steps of carbonization and steam activation. The control of process parameters (such as temperature and steam flow) is relatively simple, and operators can easily master and control the production process.

8. **Good product stability**:

Physical steam activated carbon shows good stability during storage and transportation, and is not easy to absorb moisture or undergo physical and chemical changes, which is very beneficial for long-term storage and application scenarios with high environmental requirements.

In summary, activated carbon produced by the physical steam method has significant advantages in product purity, environmental friendliness, process stability, and large-scale production. It is suitable for use in industries with high requirements for activated carbon purity and safety, as well as occasions that require large-scale, economical production. Mainly for For Gold recovery, Water treatment, Catalysts…and 30*60mesh activated charcoal for Cigarette filter.

Chapter 3

Production process of coal-based activated carbon

Coal-based activated carbon has the following main advantages:

Rich raw materials

High mechanical strength

Large adsorption capacity

Good high temperature resistance

Moderate pore structure

Coal-based activated carbon is an important adsorption material, widely used in water treatment, air purification, industrial waste gas treatment and other fields. Its production process includes raw material pretreatment, carbonization, activation and other steps. In particular, the steam activation process plays a key role in forming the pore structure of coal-based activated carbon. The following is the production process of coal-based activated carbon, focusing on the steam activation process, and comparing and analyzing the production processes of coal-based granular carbon, coal-based columnar carbon, and coal-based powdered activated carbon.

1. Raw material selection and pretreatment

- Raw material selection: Select coal with appropriate chemical composition and structure as raw material. Common types of coal include lignite, anthracite and bituminous coal. The selection of different types of coal will affect the performance of the final activated carbon.

- Crushing and screening: Crushing the coal blocks to an appropriate particle size, usually 10-100 mm. Then screen out the particle size range that meets the requirements and remove particles that are too large or too small.

2. Carbonization

- Low-temperature carbonization: Carbonize the coal in a low-temperature environment of 400°C to 700°C. The carbonization process removes the volatile components in the coal and produces a solid carbonized product (green char). This process is usually carried out in an oxygen-free or oxygen-deficient environment to prevent the material from completely burning.

3. Steam Activation Process

Steam activation is the most critical step in the production of coal-based activated carbon, which determines its final pore structure and adsorption performance. The specific process of steam activation is as follows:

- High temperature treatment: The carbonized green char is heated to a high temperature environment of 800°C to 1000°C, at which time steam is passed into the reactor as an activator.

- Gas reaction: Steam and carbon in the carbonized product undergo oxidation reaction to produce carbon monoxide and carbon dioxide. This reaction will form a large number of pores in the carbonized product, increasing its specific surface area and adsorption capacity.

- Pore formation: During the steam activation process, the intensity and duration of the reaction will directly affect the pore size and distribution of the activated carbon. By controlling the activation conditions, activated carbon with different pore structures can be produced to meet different application requirements.

- Cooling and collection: After the activation process, the activated carbon is cooled to room temperature and collected.

4.Methods for preparation and activation of coal activated carbon

Coal-based granular activated carbon production process

- Production process: Coal-based granular carbon is usually directly carbonized and steam activated by crushing and screening coal blocks. The activated product is cooled and screened to form granular activated carbon.

- Features: Granular carbon has a larger particle size (usually between 0.2-5 mm) and is mostly used for water treatment and air purification that require a longer contact time.

Coal-based activated carbon granules is a popular choice for water, and sewage treatment because it is highly effective and relatively low-cost.

It is also readily available in large quantities, making it an ideal option for large-scale sewage treatment facilities. It is mainly used for drinking water – bottled water – purification, residual chlorine removal, Industrial wastewater removal of COD, BOD, and heavy metals, River water, rainwater, steam condensate, Amine treatment, and Water filter.

High activity bituminous coal granular activated carbon for Glycerine bleaching and deodorization, Treatment of sugar solutions, Removal of dye penetrants, Textile effluent decolorization, Solvent recycling, Inorganic acid decolorization, Citric acid decolorization.

Learn more:

Coal-based pelletized activated carbon production process

- Production process: The production process of coal-based columnar carbon is similar to that of granular carbon, but before carbonization and activation, coal powder needs to be mixed with a binder and extruded into columnar particles. Then carbonization and steam activation are carried out.

- Features: The particle size and shape of columnar carbon are more uniform, usually columnar particles with a diameter of 4 mm to 10 mm. Due to its high mechanical strength and uniform pore size distribution, it is suitable for applications such as air purification and solvent recovery.

- For air treatment processes, H2S,VOCs, industrial gas, flue gas, biogas purification and natural gas…

Learn more:

Coal-based powdered activated carbon production process

- Production process: The production of coal-based powdered activated carbon is different from that of granular carbon and columnar carbon. Usually, the coal is carbonized first and then crushed into very fine particles (generally less than 75 microns), and then steam activated.

- Features: Powdered activated carbon has a larger specific surface area and faster adsorption capacity due to its small particle size. It is widely used in liquid phase adsorption, wastewater treatment, food decolorization and other fields.

Coal based powdered activated carbon widely used for wastewater treatment, water purification, COD, BOD removal,

Steel plant flue gas, cement plant flue gas treatment, waste incineration gas treatment etc.

Learn more:

5. Quality inspection and packaging

- Quality testing: Different types of coal-based activated carbon need to undergo a series of quality tests after production, such as specific surface area, pore size distribution, adsorption performance, mechanical strength, etc.

- Packaging: Depending on different application requirements, activated carbon products will be packaged in different forms to ensure their stability during transportation and storage.

Summarize

The production process of coal-based activated carbon covers multiple steps from raw material selection to final product packaging, and steam activation is the core link. Different forms of coal-based activated carbon (granular carbon, columnar carbon, powdered carbon) have some common points in the production process, such as carbonization and steam activation, but there are differences in shaping and particle size control.

These differences lead to significant differences in the adsorption performance and application fields of different types of coal-based activated carbon.