CIL Activated Carbon in Leach Gold Processing

Carbon in Leach CIL gold processing is a key part of gold refining and is the preferred refining method for many gold mines. The CIL Carbon in Leach process involves adding activated carbon to the leaching tank to perform leaching and adsorption simultaneously to extract gold from the ore.

Cyanide for gold extraction is suitable for flotation of gold concentrate or amalgam, gravity separation tailings, muddy oxide ores, high-grade large gold deposits, and gold ores with high associated silver and copper content. Cyanide gold extraction process mainly includes CIP, CIL and CIC. This article mainly introduces CIL carbon in leach process.

Table of Contents

- CIL Carbon in Leach Process for Gold Recovery

- CIL Carbon in Leach Gold Processing Factory Images

- Common Gold Extraction Chemicals in CIL Gold Processing

- Choose Heycarbons Activated Carbon in CIL Gold Processing

- Carbon in Leach VS Carbon in Pulp

CIL Carbon in Leach Process for Gold Recovery

What is the process of leaching gold?

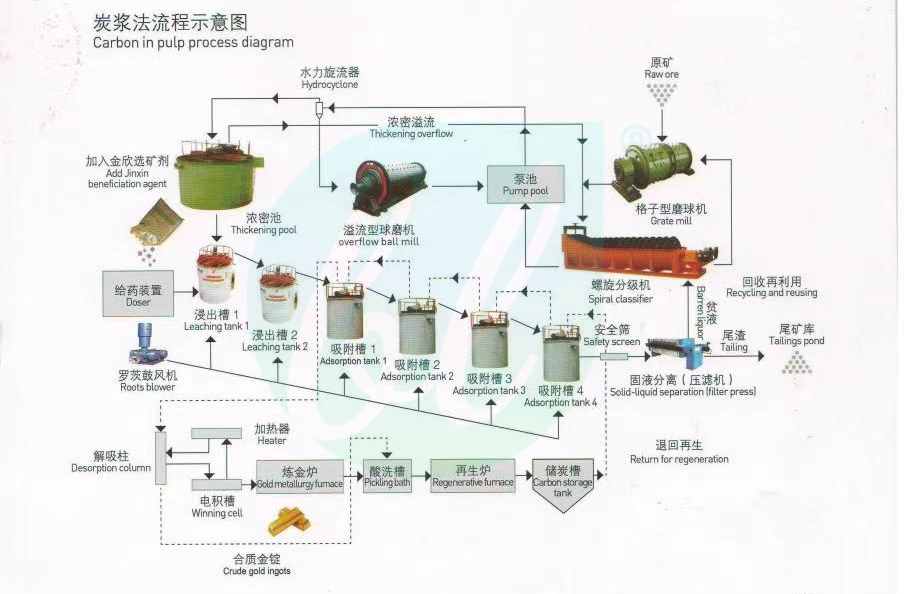

There are several main steps for CIL gold processing: ore preparation, leaching, adsorption, elution and refining.

The carbon in leach process flow diagram is as follows:

Step 1 Ore Preparation

First step of carbon in leach gold processing: The raw ore is crushed and ground to a particle size suitable for cyanidation to achieve optimal leaching. The crushing circuit may include a combination of jaw crushers, cone crushers and ball mills or semi-autogenous mills.

Step 2 Leaching

The prepared slurry is mixed with cyanide in a leaching tank or stirred leaching reactor to facilitate the dissolution of gold. Cyanide leaching solution (usually sodium or potassium cyanide) reacts with the ore to form an aqueous solution of a cyanide-gold complex.

Step 3 Adsorption

Activated carbon is added to the pregnant leaching solution to physically adsorb the gold-cyanide complexes in the solution to become gold-loaded carbon. The gold-loaded carbon is then separated from the solution by a sieve or using a screen or hopper-bottom tank design.

Step 4 Elution

The gold-loaded carbon undergoes a high temperature and high pressure elution process to desorb the gold, forming a high gold concentrate solution. The gold is then recovered from the eluate by electrolytic deposition, which is electroplated onto steel wool or steel plates. The gold precipitate is then smelted into doré bullion bars.

Step 5 Refining

High purity gold is produced through further refining of doré bullion bars.

You will get a quote in 24 hours

You will get a quote in 24 hours

CIL Carbon in Leach Gold Processing Factory Images

Common Gold Extraction Chemicals in CIL Gold Processing

In the CIL carbon in leach gold processing, different gold extraction chemicals are often used at different stages to optimize gold dissolution, adsorption and improve gold recovery.

1. Sodium Cyanide (NaCN)

Function: Mainly used as a gold leaching agent, reacting with gold in the ore to form a soluble gold-cyanide complex ([Au(CN)₂]⁻).

Chemical reaction formula is: 4Au+8NaCN+O2+2H2O→4Na[Au(CN)2]+4NaOH

2. Sodium Hydroxide (NaOH)

Function:

- Adjust the pH value of the slurry and solution to maintain between 10-11 to prevent the decomposition of cyanide and the formation of toxic hydrocyanic acid (HCN).

- In the desorption process, it is used together with sodium cyanide to promote the desorption of gold from activated carbon.

Key point: Alkaline environment helps prevent the following chemical reaction from occurring: HCN→CN−+H+

3. Sulfuric Acid (H₂SO₄) or Hydrochloric Acid (HCl)

Function: Used in the pickling process before activated carbon regeneration to remove inorganic pollutants (such as calcium, magnesium, and iron precipitation) on the carbon surface. In the wastewater treatment stage, it is used to neutralize alkaline waste liquid.

Attention: The pickling process needs to be strictly controlled to prevent damage to the activated carbon.

4. Activated Carbon

Function:

- Adsorb gold cyanide complex ([Au(CN)₂]⁻) in solution.

- Regenerate and recycle after desorption.

Requirements: High adsorption capacity and strong mechanical strength are required.

5. Lime (CaO)

Function: To adjust the alkalinity of the slurry and prevent the decomposition of cyanide to produce toxic hydrocyanic acid gas. Usually added during the grinding stage or slurry preparation stage.

You will get a quote in 24 hours

You will get a quote in 24 hours

Choose Heycarbons Activated Carbon in CIL Gold Processing

The key to choosing high-quality activated carbon for gold mining is to keep its properties and effects after repeated use for months.

Heycarb can continuously produce high-quality activated carbon for CIL carbon in leach gold processing. The carbon has high hardness and has undergone a strict carbonization and activation process, with a long service life and low wear rate. Heycarbons activated carbon widely used in CIC, CIP and CIL.

Heycarb has unique dust removal, polishing and wind selection technology in the activated carbon production process.

Heycarb factory has six large dust collectors, which can ensure that the surface of activated carbon is less dusty and clean, which helps to reduce the gold loss rate.

After crushing and screening, it enters the grinder on this side, and the scraps are polished on the other side. The polished activated carbon is more rounded and full, which will reduce wear and reduce the gold loss rate during use.

After polishing, it enters our wind selection and flake removal machine. Wind selection removes flakes and reduces the gold loss rate. The flake removal machine is based on the combination of wind power and gravity. Remove the thinner parts. Ensure the thickness and strength of each of our coconut shell gold activated carbon.

If you are looking for activated carbon for CIL gold processing plant, please contact Heycarbons. Heycarb Team has a professional sales team and can work with you to develop an efficient and economical solution.

The parameters of Heycarb coconut shell activated carbon are shown in the table below. The iodine value is generally 1100-1200. We can also customize it according to your actual needs.

| Product | Type | CTC | Surface area | Density | Hardness | Mesh size | Attrition | Platelet content |

|---|---|---|---|---|---|---|---|---|

| HEYCCGAC3 | Coconut shell base | 50-55 | 1000-1100 m2/g | 0.45-55 g/ml | >99% | 6×12, 5×10, 8×16 | <1% | <1.0% |

| HEYCCGAC4 | Coconut shell base | 60-65 | 1100-1200 m2/g | 0.42-52 g/ml | >99% | 6×12, 5×10, 8×16 | <1% | <1.0% |

You will get a quote in 24 hours

You will get a quote in 24 hours

Carbon in Leach VS Carbon in Pulp

What is the difference between carbon-in-pulp and carbon-in-leach?

Both CIP and CIL belong to cyanide gold extraction process. People also ask what the difference between carbon-in-pulp and carbon-in-leach is.

The carbon-in-pulp (CIP) process is to first perform cyanide leaching, and then add activated carbon to the slurry to adsorb gold. The carbon-in-leach (CIL) process is to add activated carbon to the leaching tank, and leaching and adsorption are carried out simultaneously.

In the CIP process, leaching and adsorption are independent operations. In the adsorption operation, the leaching process has been basically completed, and the size, number and working state of the adsorption tank are determined by the adsorption parameters.

In the CIL process, leaching and adsorption operations are carried out simultaneously. Generally, the leaching operation takes longer than the adsorption operation, so the size of the tank, the amount of aeration, and the amount of dosing are determined by the leaching parameters.

Advantages and Disadvantages

Compared with the CIP carbon in pulp gold process, the advantages of CIL Carbon in Leach Gold Processing are:

- The cost of CIL carbon in leach gold refining is lower than CIP. And the quality requirement for activated carbon is not higher than CIP.

- The leaching and adsorption processes of the CIL process are in the same reaction tank, which reduces the equipment and operation steps and simplifies the entire refining process.

- During the leaching process, the activated carbon is already in the solution, and the gold can be directly adsorbed during the gold leaching process, reducing the loss of gold. Therefore, the CIL process can usually provide a higher gold recovery rate.

- The CIL process allows leaching and adsorption to be carried out simultaneously, which can better process ores containing more impurities or complex mineral structures, and reduce the impact of impurities on the adsorption effect.

Disadvantages:

- CIL carbon in leach gold refining causes greater damage to the environment than CIL.

- During the CIL process, the cyanide concentration and redox potential of the solution must be strictly controlled, and the stability of the solution is relatively high, otherwise it may affect the solubility and recovery efficiency of gold.

If you want to know more about CIP carbon in pulp gold process, you can click:

CIP Activated Carbon in Pulp Gold Processing – Heycarb

You will get a quote in 24 hours

You will get a quote in 24 hours

K and R value of Activated Carbon For CIL Gold Extraction

Regarding the K-value and R-value of activated carbon for gold extraction, these two indicators are mainly used to evaluate the adsorption performance of activated carbon in gold extraction processes.

K-value: This refers to the gold adsorption capacity, characterizing the gold loading ability of activated carbon. It measures how much gold the activated carbon can ultimately adsorb; the higher the K-value, the greater the gold loading.

R-value: This refers to the gold adsorption rate, characterizing how quickly the activated carbon adsorbs gold. It measures the adsorption efficiency of the activated carbon; the higher the R-value, the faster the adsorption rate.

In the CIL process, leaching and adsorption occur simultaneously, with the adsorbed gold being continuously dissolved. Both the R-value and K-value are crucial.

The activated carbon must be able to quickly “capture” newly dissolved gold (requiring an R-value) and also operate continuously throughout the long process without premature saturation (requiring a K-value), much like a “marathon runner.”

You will get a quote in 24 hours

You will get a quote in 24 hours

Custom Heycarb Gold Activated Carbon Solution

Heycarbons provides a full range of activated solutions at competitive prices.

You will get a quote in 24 hours

Customize Heycarbons Activated Carbon For Gold Recovery

Heycarbons has proudly served the gold extraction activated carbon industry with high-quality products since 2005, Heycarb can customize activated carbon for your gold refining project.

- Heycarbons customized package to promote your brand, and free design service.

- Customized gold recovery carbon size, CTC, iodine value, ash, etc.

- Each batch gold extraction carbon of multiple mixed testing to ensure quality. It also supports any form of third-party testing for customers.

Call Us

+86-180 3788 5195

Our Email

info@heycarbons.com

Steps to Custom Heycarbons Activated Carbon For Gold Recovery

Consultation

By understanding your needs and requirements, our salesmen work with you to submit the appropriate activated carbon solution.

Quotation

Heycarbons expert customer service will provide you with a free quote based on your requirements as well as product specifications and quantities.

Production

Heycarbons has sufficient inventory and strong production capacity, and will report production progress to you from time to time.

Shipping

Heycarb know you need to receive the product as soon as possible, after rigorous quality checks and protective packaging, by fedex shipping.

Are You Looking for Coconut Shell Activated Carbon Manufacturers?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.

You will get a quote in 24 hours