Effect of activated carbon mesh size on flow rate and pressure drop

The mesh size of activated carbon affects its adsorption performance, flow rate, and pressure drop of the carbon bed.

Activated carbons with low mesh size (larger particles) have lower surface area and are suitable for gas treatment and air purification because they provide lower airflow resistance and higher flow rate.

Activated carbons with medium mesh size balance surface area and pore structure and are widely used in water treatment and wastewater treatment. They can effectively remove organic matter and impurities while maintaining appropriate flow rate and pressure drop.

Activated carbons with high mesh size (smaller particles) have larger surface area and higher adsorption capacity and are suitable for applications such as fine chemicals and pharmaceuticals that require high adsorption efficiency, but their flow rate is lower and the pressure drop of the carbon bed is larger.

Selecting the right mesh size of activated carbon can optimize its adsorption effect, flow rate, and pressure drop in specific applications.

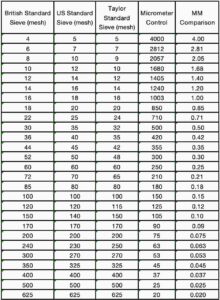

Comparison table of mesh size in different countries and mesh to mm size chart

Mesh to mm size chart:

| Standard mesh | Screen size | Standard mesh | Screen size |

|---|---|---|---|

| 4Mesh | 4.75mm | 70Mesh | 0.212mm |

| 5Mesh | 4.00mm | 80Mesh | 0.180mm |

| 6Mesh | 3.35mm | 100Mesh | 0.150mm |

| 7Mesh | 2.80mm | 120Mesh | 0.125mm |

| 8Mesh | 2.36mm | 50Mesh | 0.300mm |

| 10Mesh | 2.00mm | 60Mesh | 0.250mm |

| 12Mesh | 1.70mm | 70Mesh | 0.212mm |

| 14Mesh | 1.40mm | 80Mesh | 0.180mm |

| 16Mesh | 1.18mm | 100Mesh | 0.150mm |

| 18Mesh | 1.00mm | 120Mesh | 0.125mm |

| 20Mesh | 0.850mm | 140Mesh | 0.109mm |

| 25Mesh | 0.710mm | 150Mesh | 0.106mm |

| 30Mesh | 0.600mm | 170Mesh | 0.090mm |

| 35Mesh | 0.500mm | 200Mesh | 0.0750mm |

| 40Mesh | 0.425mm | 230Mesh | 0.0630mm |

| 45Mesh | 0.355mm | 270Mesh | 0.0530mm |

| 50Mesh | 0.300mm | 325Mesh | 0.0450mm |

| 60Mesh | 0.250mm | 400Mesh | 0.0374mm |

Common mesh and mm sizes of activated carbon.

1) Powdered activated carbon (PAC):

- Powdered activated carbon mesh size chart is generally 50*120 mesh, 80*150 mesh, 100 mesh, 200 mesh, 325 mesh,600mesh.

| Powdered activated carbon mesh size chart | |

| 50*120 mesh=0.3~0.125mm | 100mesh =150um=0.15mm |

| 80*150 mesh=0.18~0.106mm | 200mesh =75um=0.075mm |

| 600mesh=23um=0.023mm | 325mesh =45um=0.045mm |

- Mainly used for water treatment and air purification, adsorption of organic matter and harmful gases.

2) Granular activated carbon (GAC):

- Granular activated carbonmesh size table is generally 4*8 mesh, 8*16 mesh, 8*30 mesh, 12*40 mesh, 30*60 mesh, 80*150 mesh.

| Granular activated carbon mesh size table | |

| 4*8mesh=4.75~2.36mm | 8*16 mesh=2.36~1.18mm |

| 8*30 mesh=2.36~0.6mm | 12*40 mesh=1.7~0.425mm |

| 30*60 mesh=0.6~0.25mm | 80*150 mesh=0.18~0.106mm |

- Commonly used in water treatment, wastewater treatment, gas treatment and food, sugar, oil decolorization and other processes.

3) Pelletized Activated Carbon(PAC):

- Pelletized Activated Carbonmesh size chart is generally 0.9mm, 1.5mm, 2mm, 3mm, 4mm, 5mm, 6mm, 8mm.

| Pelletized Activated Carbon mesh size chart | |||

| 0.9mm | 1.5mm | 2mm | 3mm |

| 4mm | 5mm | 6mm | 8mm |

- Mainly used for gas phase adsorption applications, H2S and VOC adsorption in air treatment, and purification of industrial gas, flue gas, biogas and natural gas.

These activated carbons of different shapes and sizes have different adsorption properties and effects in different application scenarios. Choosing the right size and type of activated carbon can improve its efficiency and economy.