Activated Carbon For Condensate Water Heycarbons Manufacturer From China

What is Condensed Water?

Condensate refers to water formed when gas (usually water vapor in the air) condenses under the condition of lower temperature or pressure change. The formation of condensate usually occurs in cooling equipment, air conditioners, cooling towers, condensers and other systems. When these devices are working, by cooling gas or steam, water vapor condenses into liquid water, which is condensate.

During the cooling process, condensate will come into contact with impurities in the air and may contain trace amounts of organic matter, dissolved gases and other pollutants. If it is not treated, it may affect the performance of the equipment and even cause secondary pollution.

For recycled condensate used for cleaning, cooling and other purposes, it is necessary to ensure that the water quality of the condensate meets the standards to avoid harm to subsequent equipment, personnel or the environment.

You will get a quote in 24 hours

You will get a quote in 24 hours

How to Use Activated Carbon For Condensate Water?

Activated carbon has a strong adsorption capacity due to its developed pore structure and large specific surface area. In the condensate treatment system, it is mainly installed in the treatment device as a filter medium to remove pollutants such as organic matter, odor, dissolved gas, etc. in the water by physical adsorption.

1. Activated carbon filter (carbon filter)

This is the most common form:

- Activated carbon is placed in a pressure vessel, and condensate passes through the carbon layer from top to bottom.

- Pollutants in the water are adsorbed on the surface or pores of the carbon particles.

- The treated water flows out through the outlet and enters the subsequent process or recovery system.

Suitable scenarios: large-scale centralized condensate treatment system, central air conditioning condensate recovery system, industrial condenser outlet water purification.

2. Activated carbon filter element (replaceable)

Suitable for small or decentralized systems, such as commercial air conditioning, small condensation systems, etc.:

- Installed in a filter housing (such as a pipeline filter), the filter element is filled with activated carbon particles or compressed carbon rods.

- Easy to use, simple maintenance, suitable for local treatment.

3. Combined with a multi-stage treatment system

Activated carbon is often used as a part of the water treatment process, combined with a pre-filter (removal of suspended matter) and a post-sterilization device (such as ultraviolet disinfection) to form a complete condensate treatment process.

You will get a quote in 24 hours

You will get a quote in 24 hours

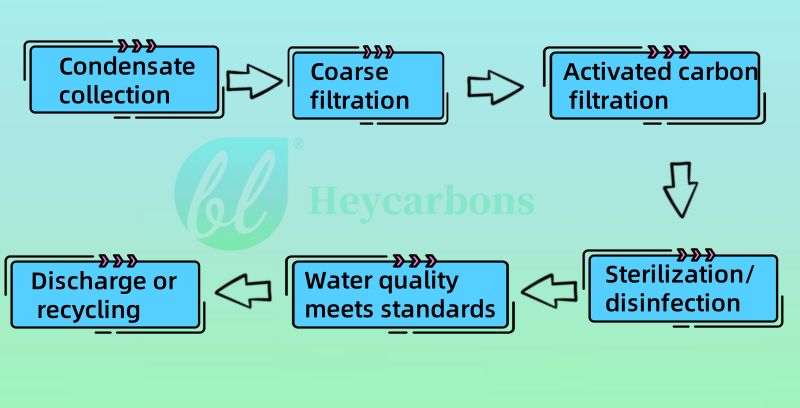

Activated Carbon For Condensate Treatment Process

The following is an introduction to the process of using activated carbon to treat condensed water: collecting condensed water, coarse filtration to remove particulate impurities, activated carbon adsorbing organic matter and odor, sterilization and disinfection, and discharging or recycling water after it meets the quality standards.

Collection of condensed water

1. Sources of condensed water-Condensed water generally comes from the following systems:

- Evaporator or condenser of air conditioning system

- Industrial refrigeration equipment

- Condensation section of boiler system

- Cooling tower or heat exchanger surface

2. Collection device

The system is equipped with condensed water receiving tray and drainage pipe to guide the generated condensed water to centralized water storage tank or treatment station.

Pretreatment stage (physical filtration)

1. Coarse filtration (removal of particulate impurities)

Condensate may contain dust, rust particles, impurities in the air or debris inside the building. Coarse filters or mesh filters (such as stainless steel mesh, plastic screen) can be used to remove particulate matter.

2. Sedimentation tank (if necessary)

If the condensate volume is large and contains precipitable impurities, a small sedimentation tank can be set up to allow heavy particles to settle.

Activated carbon adsorption treatment (core purification step)

1. Set up the activated carbon filtration unit

- Use a pressure vessel or carbon filter column filled with granular activated carbon (GAC).

- The condensed water flows through the carbon layer from top to bottom.

2. Activated carbon adsorption mechanism

- The porous structure of activated carbon has a strong adsorption capacity for organic matter, dissolved gases (such as ammonia, hydrogen sulfide), and odor substances in water.

- Activated carbon can also adsorb some trace heavy metals, pigments, chemical residues, etc.

3. Operation control

- Control the residence time (contact time) of water to ensure the adsorption effect.

- Regularly replace or regenerate the activated carbon to prevent adsorption saturation and pollutant penetration.

Sterilization and disinfection treatment

1. Microbial control requirements

If the condensed water needs to be stored, reused or used for non-direct contact purposes (such as greening), it should be further sterilized.

2. Common methods

There are two common sterilization methods

- Ultraviolet disinfection (UV): Kill bacteria, viruses and other microorganisms in water through ultraviolet light.

- Ozone/chlorine disinfection: Used to kill residual biological contamination that cannot be treated by activated carbon.

Emission treatment after reaching the standard

- Test the COD, BOD, ammonia nitrogen, total dissolved solids (TDS) and other indicators of the discharge water according to local environmental protection regulations.

- If it does not meet the standards, it is necessary to add a biochemical treatment unit or a membrane filtration system (such as ultrafiltration/reverse osmosis) to ensure that the discharge water meets the standards.

You will get a quote in 24 hours

You will get a quote in 24 hours

Activated Carbon For Condensate Polishing Effects

Adsorption of organic pollutants

Condensate may carry organic matter from the air, dissolved gases and other trace pollutants. Activated carbon has a very large surface area and can effectively adsorb organic matter in water, such as grease, solvents, aromatic hydrocarbons, etc., to reduce water pollution.

Removal of dissolved gases

Activated carbon can not only remove solid pollutants from water, but also adsorb dissolved gases in water, such as ammonia, hydrogen sulfide, nitrogen oxides, etc. These gases usually affect the quality of water and even produce odors. Activated carbon can effectively remove these harmful gases and purify water quality.

Removal of odor and color

Due to the strong adsorption properties of activated carbon, it can remove odor and color from water. Especially when condensate comes from industrial or commercial environments, it may have some unpleasant odors or dirty colors. The use of activated carbon can significantly improve these problems.

Economic and renewability

Activated carbon is more economical than other treatment materials (such as chemicals) and can be regenerated by heating or other methods, which makes it low-cost in long-term use and suitable for continuous operation.

Wide applicability

Activated carbon has a good removal effect on different types of pollutants, especially for condensate water treatment that requires high standards of purification, activated carbon provides a very effective solution. It works better when used in combination with other water treatment technologies (such as reverse osmosis, ultraviolet disinfection, etc.).

You will get a quote in 24 hours

You will get a quote in 24 hours

Heycarbons Activated Carbon For Condensate Polishing

HEYCARB-CON is a extremely high purity, acid washed coco granular activated carbon manufactured by steam activation. This activated carbon is produced principally for use in condensate recovery water treatment systems requiring low conductivity and exceptionally strict control of the levels of silica content present in the treated water.

Heycarbons acid-washed coconut shell activated carbon has few impurities, is relatively pure, has low ash content, and the maximum ash content is only 1%. It is the most suitable activated carbon for condensate polishing.

HEYCARB-CON exhibits a high capacity for dissolved oils and hydrocarbons that pass into the condensate during recirculation and prevents the deposition of these contaminants on downstream equipment. HEYCARB-CON is available in a variety of particle size distributions to suit all hydraulic requirements.

You will get a quote in 24 hours

Heycarbons Activated Carbon For Condensate Specifications

| Specification | HEYCARB-CON |

|---|---|

| Available particle sizes/ mesh | 8×18, 8×30, 10×20, 12×40, 20×40, etc.(Customized according to customer) |

| Iodine adsorption | min. 1000 mg/g |

| Moisture content, as packed | max. 5 % |

| Apparent density | min. 450 kg/m3 |

| Total ash content | max. 1% |

| pH | 5 – 7 |

| Methylene blue adsorption | min. 115 ml/g |

| CTC activity | min. 50% |

For more specific activated carbon parameters, please click the link below to contact heycarbons. Tell us your specific needs and heycarbons will provide you with the most suitable activated carbon products.

You will get a quote in 24 hours

You will get a quote in 24 hours

Activated Carbon For Condensate Polishing Applications

Using activated carbon to treat condensate can be used in the following scenarios:

Air conditioning system condensate recovery

Condensate may contain dust, organic matter, bacteria and odor components in the air.

Through preliminary filtration + activated carbon adsorption + sterilization treatment, the water quality can be significantly improved, and odor and organic pollutants can be removed.

The treated condensate can be safely reused for non-drinking purposes such as flushing toilets, greening sprinkler irrigation, road washing, etc., saving a large amount of tap water resources and reducing the cost of building water.

Industrial cooling systems

Using activated carbon filters can effectively remove pollutants such as volatile organic compounds (VOCs), trace oils, and odors in condensed water.

The purified condensed water can be used as boiler water, cooling tower water, or equipment cleaning water to extend the service life of the equipment.

This can avoid the accumulation of pollutants that cause a decrease in heat exchange efficiency or system corrosion, and ensure stable operation of the system.

Commercial Condensate Drainage Purification System

Activated carbon filtration can remove organic pollutants, odors, colors and soluble impurities to improve water quality.

If combined with microbial control (such as ultraviolet disinfection), it can completely purify the discharge water and prevent microbial contamination.

Treated condensate can be discharged stably and meet the standards, avoiding environmental penalties or social responsibility risks for enterprises due to excessive water quality.

Water recycling in condensing boilers or refrigeration units

Activated carbon can absorb residual combustion byproducts, volatile organic residues and metal particles brought in by equipment operation.

Treated condensed water can be used for closed-loop cooling, boiler water replenishment, equipment flushing and other scenarios.

Effectively recovering condensed water can reduce fresh water consumption, improve system water efficiency, extend equipment life, and reduce scaling, corrosion and maintenance costs.

You will get a quote in 24 hours

You will get a quote in 24 hours

Steps to Custom Heycarbons Activated Carbon For Condensate Polishing

Consultation

By understanding your needs and requirements, our salesmen work with you to submit the appropriate activated carbon solution.

Quotation

Heycarbons expert customer service will provide you with a free quote based on your requirements as well as product specifications and quantities.

Production

Heycarbons has sufficient inventory and strong production capacity, and will report production progress to you from time to time.

Shipping

Heycarbons know you need to receive the product as soon as possible, after rigorous quality checks and protective packaging, by fedex shipping.

Heycarbons Factory Tour

Why Choose Heycarbons Activated Carbon?

Heycarbons has proudly served the activated carbon industry with high-quality products for over 20 years with 16 patents.

- First, on the left you can see what our customers say about us?

- Secondly, we have extensive experience in the food decolorization industry.

- When encountering problems, we actively respond to ensure a good customer experience

You will get a quote in 24 hours

Contact Heycarbons

Let’s Get in Touch

We’re open for any suggestion or just to have a chat

Contact with us

We will give you the help you need

Floor 20, Building 2, Binhu International City, Erqi District, Zhengzhou City, Henan Province

Are You Looking for Activated Carbon Manufacturers?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.

You will get a quote in 24 hours