CIP Activated Carbon in Pulp Gold Processing

CIP-Carbon in pulp method is an extraction technology for gold recovery. The CIP carbon in pulp gold extraction process is a method of adding activated carbon to the cyanide slurry, adsorbing the dissolved gold onto the activated carbon, and extracting gold from the activated carbon.

Cyanide for gold extraction is suitable for flotation of gold concentrate or amalgam, gravity separation tailings, muddy oxide ores, high-grade large gold deposits, and gold ores with high associated silver and copper content. Cyanide gold extraction process mainly includes CIP, CIL and CIC. This article mainly introduces CIP process.

Table of Contents

- CIP Carbon in Pulp Method for Gold Recovery

- Common Gold Extraction Chemicals in CIP Process

- Choose Heycarbons Activated Carbon in CIP Gold Processing

- Carbon in Leach VS Carbon in Pulp

CIP Carbon in Pulp Method for Gold Recovery

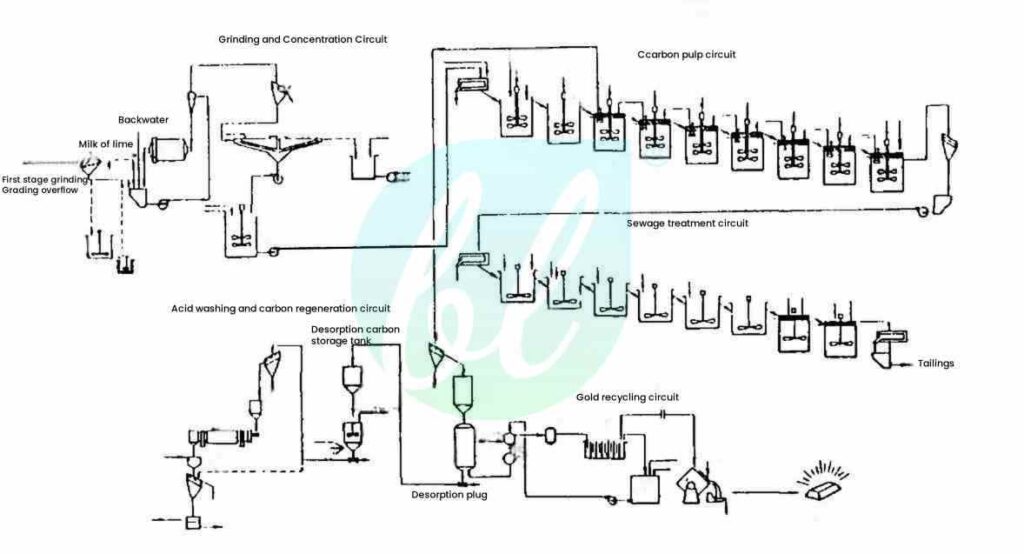

What is ClP in gold processing? The carbon in pulp process flow sheet is shown in the figure:

There are six main steps for gold CIP process: ore preparation, leaching, adsorption, desorption and elution, electrolysis and activated carbon regeneration.

Step 1 Ore Preparation

The grinding circuit is divided into two closed-circuit processes. Grinding can crush the gold-containing raw ore into a particle size suitable for cyanidation, generally 200 mesh, and the ore fineness can reach 90%.

In the grinding concentration circuit, two chip screens can remove impurities such as wood chips and detonating cords from the slurry.

Step 2 Leaching

The carbon leaching system has nine tanks, two pre-leaching tanks and seven carbon leaching tanks. 0.1MPa compressed air is added to each tank through the hollow shaft of the agitator to produce fine bubbles, provide the oxygen required in the leaching process, and also play an auxiliary stirring role.

The pre-leaching tank consumes a lot of oxygen, and the leaching reaction is mainly carried out in the pre-leaching tank.

Step 3 Adsorption

The adsorption process is carried out in seven carbon leaching tanks. Lime and sodium cyanide are added to the carbon leaching tank, and compressed air enters the tank for leaching and adsorption. Activated carbon is added to the fully leached slurry, usually the No. 7 carbon leaching tank, and flows in the opposite direction to the ore slurry. Activated carbon adsorbs gold in the cyanide slurry and becomes gold-containing carbon.

Step 4 Desorption and Elution

Elution process gold of removing gold from the gold-containing carbon separated from the gold removal slurry is called desorption.

The gold-containing carbon extracted from the carbon leaching tank is vibrated, the ore mud is screened out, and it is stored in the gold-containing carbon storage tank.

The desorption column is located at the bottom of the storage tank, and its carbon loading capacity is 700kg. The desorption operation is carried out under high temperature and high pressure, and forms a closed loop with the electrolysis operation. Desorption and electrolysis operations are carried out in batches.

The desorption liquid is composed of 1% NaCN and 1% NaOH, and the desorption liquid is injected into the desorption column using a metering rod. The pressure in the desorption column is controlled by a pneumatic pressure regulating valve to keep it at 0.31MPa.

Before entering the desorption column, the desorption liquid is preheated by a heat exchanger, and then heated by two electric heaters to 135 ℃ before entering the desorption column. The desorption liquid washes the gold on the gold-containing carbon under high temperature and high pressure to achieve gold elution.

Step 5 Electrolysis

The gold-containing solution discharged from the desorption column enters the electrolytic cell after filtration and cooling. The gold in the solution is deposited on the cathode in the electrolytic cell. After the cathode gold mud is extracted, the gold and silver are separated and smelted in the smelting room.

Step 6 Activated Carbon Regeneration

The activated carbon after desorption is first washed with dilute sulfuric acid (nitric acid) to remove carbonates and other accumulations. After several cycles, it needs to be heated and regenerated to restore adsorption activity. It can then be returned to the carbon leaching system for recycling.

You will get a quote in 24 hours

You will get a quote in 24 hours

Common Gold Extraction Chemicals in CIP Process

In the CIP carbon in pulp gold processing, different gold extraction chemicals are often used at different stages to optimize gold dissolution, adsorption and improve gold recovery.

1.Sodium cyanide (NaCN)

Function: Sodium cyanide is the core chemical reagent in the CIP carbon in pulp gold processing. It’s usually used in gold ore leaching reactions and can effectively dissolve gold.

Chemical reaction formula: 4Au+8NaCN+2H2O+O2→4Na[Au(CN)2]+4NaOH

In this reaction, sodium cyanide reacts with gold to form a soluble gold cyanide complex (Na[Au(CN)₂]).

2.Potassium cyanide (KCN)

Function: Potassium cyanide has similar functions to sodium cyanide and is also used to leach gold. It often replaces sodium cyanide when sodium cyanide is in short supply or under specific process conditions.

Chemical reaction formula: 4Au+8KCN+2H2O+O2→4K[Au(CN)2]+4KOH

Potassium cyanide also reacts with gold to form a soluble gold cyanide complex (K[Au(CN)₂]).

3.Sodium metaphosphate (NaPO3)

In the CIP carbon in pulp gold extraction, sodium metaphosphate (Na₃PO₄) is mainly used as an auxiliary agent to adjust the pH value and dissolve chemical reactions.

Adjusting pH value: During the CIP process, cyanide (CN⁻) forms a gold cyanide (Au(CN)₂⁻) complex with gold (Au). As a buffer, sodium metaphosphate can effectively adjust the pH value of the reaction system, thereby promoting the formation of gold cyanide complexes and optimizing the leaching effect.

Sodium metaphosphate may react with other impurity metal ions (such as iron), and the chemical reaction formula is as follows: Fe3++PO₄³⁻→FePO4

The phosphate (PO₄³⁻) of sodium metaphosphate can form insoluble phosphates with iron ions, reducing the interference of iron ions and improving the stability of gold cyanide complexes.

4.Sodium sulfite (Na₂SO₃)

Function: Sodium sulfite is a reducing agent, used to reduce the gold in the gold cyanide complex to metallic gold in the CIP process, thereby extracting gold.

Chemical reaction formula: Au(CN)2−+2Na2SO3+H2O→Au+2Na2SO4+2CN−

5.Soda ash (Na₂CO₃)

The cyanidation reaction in the CIP process needs to maintain appropriate alkaline conditions. Soda ash is used to increase the pH value of the solution to a range suitable for the cyanidation reaction (usually 9.5-11), which can effectively promote the dissolution of gold.

Chemical reaction formula: Na2CO3→2Na++CO32−

6.Sodium amyl xanthate (Xanthate)

Sodium Amyl Xanthate is mainly used in flotation process, but in some CIP gold extraction processes, it can also help separate metal impurities and improve gold extraction efficiency.

In complex ores, Sodium Amyl Xanthate can help separate other metal elements (such as copper, lead, etc.) from the ore pulp and increase the gold leaching rate. Reduce impurity interference, improve the purity of gold ore, and make gold cyanide extraction more efficient.

7.Ammonium butyl black medicine

Ammonium butyl black medicine is used as an auxiliary reagent in CIP, mainly for flotation process or impurity control, to reduce the interference of other metals in the gold extraction process. It helps to improve the purity of gold cyanide and improve the leaching efficiency of gold.

You will get a quote in 24 hours

You will get a quote in 24 hours

Why Choose Heycarbons Activated Carbon in CIP Gold Processing?

The key to choosing high-quality activated carbon for gold mining is to keep its properties and effects after repeated use for months.

Heycarb can continuously produce high-quality activated carbon for CIP carbon in pulp gold processing. The carbon has high hardness and has undergone a strict carbonization and activation process, with a long service life and low wear rate. Heycarbons activated carbon widely used in CIC, CIP and CIL.

Heycarb has unique dust removal, polishing and wind selection technology in the activated carbon production process.

Heycarb factory has six large dust collectors, which can ensure that the surface of activated carbon is less dusty and clean, which helps to reduce the gold loss rate.

After crushing and screening, it enters the grinder on this side, and the scraps are polished on the other side. The polished activated carbon is more rounded and full, which will reduce wear and reduce the gold loss rate during use.

After polishing, it enters our wind selection and flake removal machine. Wind selection removes flakes and reduces the gold loss rate. The flake removal machine is based on the combination of wind power and gravity. Remove the thinner parts. Ensure the thickness and strength of each of our coconut shell gold activated carbon.

If you are looking for activated carbon for CIP gold processing plant, please contact Heycarbons. Heycarb Team has a professional sales team and can work with you to develop an efficient and economical solution.

The parameters of Heycarb coconut shell activated carbon are shown in the table below. The iodine value is generally 1100-1200. We can also customize it according to your actual needs.

| Product | Type | CTC | Surface area | Density | Hardness | Mesh size | Attrition | Platelet content |

|---|---|---|---|---|---|---|---|---|

| HEYCCGAC1 | Coconut shell base | 50-55 | 1000-1100 m2/g | 0.45-55 g/ml | >99.8% | 6×12, 5×10, 8×16 | <1% | <1.0% |

| HEYCCGAC2 | Coconut shell base | 60-65 | 1100-1200 m2/g | 0.42-52 g/ml | >99.8% | 6×12, 5×10, 8×16 | <1% | <1.0% |

You will get a quote in 24 hours

You will get a quote in 24 hours

Carbon in Leach VS Carbon in Pulp

What is the difference between carbon in leach and carbon in pulp?

Both CIP and CIL belong to cyanide gold extraction process. People also ask what the difference between carbon in leach and carbon in pulp is.

The carbon-in-place (CIP) process is to first perform cyanide leaching, and then add activated carbon to the slurry to adsorb gold. The carbon-in-place (CIL) process is to add activated carbon to the leaching tank, and leaching and adsorption are carried out simultaneously.

In the CIP process, leaching and adsorption are independent operations. In the adsorption operation, the leaching process has been basically completed, and the size, number and working state of the adsorption tank are determined by the adsorption parameters.

In the CIL process, leaching and adsorption operations are carried out simultaneously. Generally, the leaching operation takes longer than the adsorption operation, so the size of the tank, the amount of aeration, and the amount of dosing are determined by the leaching parameters.

Advantages and Disadvantages

Compared with the CIL carbon in leach gold processing, the advantages of CIP carbon in pulp process are:

- The CIP process separates leaching and adsorption, requires fewer reaction tanks than CIL, has a simple equipment structure, and has a lower initial equipment investment.

- Since the leaching and adsorption processes are separate, its operation is more flexible, and the parameters of the leaching and adsorption stages can be adjusted according to different ore conditions.

- The CIP process is suitable for large-scale mining operations, especially when the gold content in the ore is high, it can efficiently recover gold.

- CIP carbon in pulp is less destructive to the environment than CIL.

Disadvantages:

- CIP carbon in leach has higher quality requirements for activated carbon than CIL.

- Leaching and adsorption are carried out separately, because activated carbon cannot directly participate in adsorption at the beginning of the leaching process, which may cause some gold to fail to be adsorbed in time. The gold recovery rate is relatively low.

- Although the initial investment is low, the CIP process requires multiple adsorption tanks and desorption equipment, which may increase subsequent operating costs and maintenance workload.

If you want to know more about CIL carbon in pulp gold process, you can click:

https://heycarbons.com/cil-carbon-in-leach-gold-process/

Please contact heycarbons, we can help you choose the appropriate gold process according to your needs.

You will get a quote in 24 hours

You will get a quote in 24 hours

K and R value of Activated Carbon For CIP Gold Extraction

Regarding the K-value and R-value of activated carbon for gold extraction, these two indicators are mainly used to evaluate the adsorption performance of activated carbon in gold extraction processes.

K-value: This refers to the gold adsorption capacity, characterizing the gold loading ability of activated carbon. It measures how much gold the activated carbon can ultimately adsorb; the higher the K-value, the greater the gold loading.

R-value: This refers to the gold adsorption rate, characterizing how quickly the activated carbon adsorbs gold. It measures the adsorption efficiency of the activated carbon; the higher the R-value, the faster the adsorption rate.

In the CIP process, leaching precedes adsorption, with the adsorption target being a high concentration of dissolved gold.

The R-value (adsorption rate) is the primary critical factor, requiring the activated carbon to react rapidly, acting like a “goalkeeper,” to prevent the loss of dissolved gold. The K-value determines the operating cost.

You will get a quote in 24 hours

You will get a quote in 24 hours

Custom Heycarb Gold Activated Carbon Solution

Heycarbons provides a full range of activated solutions at competitive prices.

You will get a quote in 24 hours

Customize Heycarb Gold Activated Carbon

Heycarbons has proudly served the gold extraction activated carbon industry with high-quality products since 2005, Heycarb can customize activated carbon for your project.

- Heycarbons customized package to promote your brand, and free design service.

- Customized gold recovery carbon size, CTC, iodine value, ash, etc.

- Each batch gold extraction carbon of multiple mixed testing to ensure quality. It also supports any form of third-party testing for customers.

Call Us

+86-180 3788 5195

Our Email

info@heycarbons.com

Steps to Custom Heycarb GOLD Activated Carbon

Consultation

By understanding your needs and requirements, our salesmen work with you to submit the appropriate activated carbon solution.

Quotation

Heycarbons expert customer service will provide you with a free quote based on your requirements as well as product specifications and quantities.

Production

Heycarbons has sufficient inventory and strong production capacity, and will report production progress to you from time to time.

Shipping

Heycarb know you need to receive the product as soon as possible, after rigorous quality checks and protective packaging, by fedex shipping.

Are You Looking for Coconut Shell Activated Carbon Manufacturers?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.

You will get a quote in 24 hours