Activated Carbon For Siloxane Removal

Siloxanes are man-made silicone compounds commonly found in silicone oils, silicone rubbers, lubricants, sealants, cosmetics, shampoos and other products. The widespread use of these products has led to a significant increase in the content of siloxanes in wastewater treatment, landfills and anaerobic digestion measures.

What is Siloxane?

Siloxanes are man-made silicone compounds commonly found in silicone oils, silicone rubbers, lubricants, sealants, cosmetics, shampoos and other products. The widespread use of these products has led to a significant increase in the content of siloxanes in wastewater treatment, landfills and anaerobic digestion measures.

Hazards of siloxanes

Environmental toxicity: Some siloxanes (such as cyclic D4 and D5) are bioaccumulative and may cause long-term harm to aquatic organisms.

Industrial impact: Siloxanes in biogas will burn in gas turbines or internal combustion engines and form silicon dioxide (silicon dioxide, SiO₂) or silicates (SiₓOy). This silica and silicates will accumulate on valves, cylinder walls, bushings and turbine blades, causing equipment wear, blockages and mechanical failures.

Health risks: Long-term inhalation may irritate the respiratory tract, but siloxanes in ordinary daily products are generally considered to be safe.

You will get a quote in 24 hours

You will get a quote in 24 hours

Activated Carbon For Siloxane Adsorption Mechanism

1. Physical adsorption (dominant)

- Activated carbon has a large specific surface area (up to several hundred to thousands of m²/g) and a rich pore structure (micropores, mesopores, and macropores).

- Siloxanes are a class of volatile organic silicon compounds (VOSiCs) with large molecules but certain volatility, which can enter the pores of activated carbon.

- Adsorption on the pore wall by van der Waals forces, mainly in the micropore area.

2. Molecular size matching: why is activated carbon a good adsorbent?

The pore size of activated carbon (especially micropores 0.5–2 nm) is a good match for certain molecular sizes of siloxanes (e.g., D4, D5), thus enhancing the selective adsorption.

3. Hydrophobic interactions

Siloxane molecules are usually hydrophobic (such as D4, D5), and the hydrophobic areas on the activated carbon surface facilitate their adsorption.

Hydrophobic interactions enhance the residence time of non-polar siloxanes on the activated carbon surface.

4. Catalytic reaction

Under the catalysis of KOH, siloxane can be hydrolyzed to generate silanol, which in turn forms insoluble silica deposits, achieving the removal of siloxane. The detailed chemical mechanism you will see below of this article.

You will get a quote in 24 hours

You will get a quote in 24 hours

What Does Activated Carbon Absorb?

Common siloxanes that can be removed by activated carbon

| Siloxane Type | Molecular formula | Typical existence scenario | Activated carbon adsorption performance |

|---|---|---|---|

| L2 | C6H18OSi2 | Biogas, lubricants, silicone oil volatiles, coatings | Very easy to adsorb (small molecules, high volatility) |

| D3 | C6H18O3Si3 | Cosmetics, shampoo, defoaming agent | Easy to adsorb (small molecules) |

| D4 | C8H24O4Si4 | Biogas, cosmetics, skin care products | Moderately easy to adsorb (well matched pore size) |

| D5 | C10H30O5Si5 | Antiperspirants, hair conditioners, landfill gas | Slower adsorption (larger molecules) |

| D6 | C12H36O6Si6 | High-end skin care products, industrial silicone solvents | Difficult to adsorb (molecules are too large) |

| MDM or L3 | C8H24O2Si3 | Medical silicone oil, industrial coating | Easy to adsorb (linear molecules, fast diffusion) |

Siloxane Removal From Biogas Activated Carbon

Gas Treatment

1. Gas pretreatment

Use cyclone separators, degreasers, coarse filters and other equipment to remove large particles of impurities, oil mist, moisture, etc.

2. Dehumidification and cooling

The adsorption efficiency of siloxane will decrease under humid conditions. The gas needs to pass through a cooler, condenser or drying tower to reduce the gas temperature and condense the water, so as to ensure that the gas humidity is less than 50% (or lower) before entering the activated carbon.

3. Dust removal and filtration

Use high-efficiency filters (HEPA or F9 grade) to remove fine particles and prevent clogging of activated carbon channels. This can keep the system running stably for a long time.

Activated Carbon Adsorption Stage

Adsorption tower design

- Fixed bed: most common, single tower or multiple towers in parallel/series (multiple towers for continuous operation).

- Fluidized bed: suitable for high flow rate and large flow gas, but the activated carbon wear is larger.

Operation parameters

- Empty tower gas velocity: 0.1-0.5 m/s (to ensure sufficient contact time).

- Bed height: usually 1-2 m, pressure drop controlled at 5-15 kPa.

- Adsorption temperature: 20-40℃ (optimal range for physical adsorption).

Monitoring indicators

Siloxane concentration of outlet gas (online GC or PID detector), switch the tower when the breakthrough concentration reaches the set value (such as 1 mg/m³).

Thermal Regeneration of Activated Carbon From Biogas

- Desorption: Inert gas (such as N₂) is purged and heated to 200-300°C to desorb siloxane.

- Condensation recovery: The desorbed gas is liquefied through a condenser (-10 to 5°C) to collect siloxane.

- Activation of activated carbon: Water vapor or CO₂ is passed through to partially oxidize and restore pores (optional).

You will get a quote in 24 hours

You will get a quote in 24 hours

Factors Affecting Adsorption Performance

1. Pore structure

Activated carbon with a high proportion of micropores is more effective for low molecular weight siloxanes (such as L2), while mesopores help adsorb larger molecules (such as D4, D5).

2. Specific surface area

The higher (usually >1000 m²/g), the greater the adsorption capacity.

3. Temperature

Low temperatures (such as 20-40°C) are conducive to physical adsorption, and high temperatures (>100°C) may cause desorption.

4. Humidity

Under high humidity conditions, moisture may compete for adsorption sites and reduce the amount of siloxane adsorption.

You will get a quote in 24 hours

You will get a quote in 24 hours

Activated Carbon For Siloxane Removal From Landfill Gas Customer Case

A Lebanese customer wanted activated carbon to absorb the siloxanes from the landfill gas supplying the gas engines. He found Heycarbons and asked for a quote. We customized a suitable activated carbon TDS according to his needs and sent relevant samples.

- Modified extruded activated carbon

- Impregnated with 8% KOH

- CTC 60%

If you have the same needs, please feel free to contact heycarbons at any time. Heycarbons is online 24*7.

KOH Impregnated Activated Carbon for Siloxane Removal Chemical Mechanism

The removal of siloxanes by KOH-impregnated activated carbon is mainly achieved through the following mechanisms:

(1) KOH-induced hydrolysis reaction

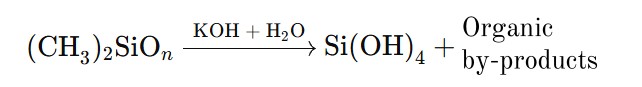

KOH reacts with siloxanes to cause base-catalyzed hydrolysis and cleavage:

That is:

The Si–O–Si bond breaks under alkaline conditions;

Silicon alcohols (such as Si(OH)₄) or precipitates (silicon dioxide) are generated.

(2) Formation of solid deposits (silicon dioxide)

The hydrolysis products (such as silanols) further condense under high temperature or dry conditions to form insoluble silicon dioxide deposits:

Si(OH)4→SiO2(s)+2H2O

These deposits adhere to the pores of the activated carbon, resulting in permanent removal of siloxanes rather than simple physical adsorption.

Heycarbons Activated Carbon Siloxane Removal Products

Heycarbons’ extruded activated carbon siloxane removal can be impregnated with KOH , unimpregnated, or use coconut shell granular activated carbon impregnated KOH.

Heycarbons can also customize activated carbon according to the specific needs of customers. More information, such as activated carbon siloxane price, please contact heycarbons.

Coal extruded activated carbon for siloxane removal specification

- 4mm coal pelletized activated carbon

- CTC50-70

- Impregnation KOH solution content 6-10%

Coconut shell granular activated carbon for siloxane removal specification

- 4-8/4-16 mesh

- Iodine value 900-1100mg/g

- Impregnation KOH solution content 7-10%

About activated carbon adsorption efficiency for siloxane removal

For siloxane adsorption, customers are using CTC60 coal-based activated carbon, combined with regeneration process.

- Efficiency of activated carbon CTC 60 absorbs siloxane: 15-20%

- Efficiency of KOH impregnated activated carbon CTC 60 absorbs siloxane: 20-25%

If you want to know more about the adsorption efficiency of activated carbon with different CTC values for siloxane, please contact heycarbons. We can also customize it according to your needs.

You will get a quote in 24 hours

You will get a quote in 24 hours

Activated Carbon For Siloxane Removal Applications

1. Biogas/biogas purification

In landfill gas power generation, biomass power generation projects, etc., activated carbon can effectively adsorb trace amounts of volatile siloxanes (such as D4, D5) in biogas, protecting generator sets and cogeneration equipment.

2. Compressed air and gas system purification

In compressed air, the source of siloxane may be certain lubricants or sealing materials. Activated carbon filters are used to remove siloxane to avoid contamination in high-cleanliness scenarios such as spraying and electronic component manufacturing.

3. Waste gas treatment in the cosmetics and pharmaceutical industries

Siloxane is widely used in skin care products, shampoo, conditioner, etc., and may enter the ventilation system during the emission process. The activated carbon system can be used for waste gas treatment or workshop tail gas purification to reduce the impact of siloxane on equipment and the environment.

4. Exhaust gas treatment in silicone factories

The production process of organic silicon materials will release a large number of different types of siloxane gases. Activated carbon towers or activated carbon module systems are widely used for pretreatment or tail gas treatment, especially in low-concentration emission sections.

5. Fuel cell system protection

Some fuel cells are extremely sensitive to impurities. Even trace amounts of siloxane can seriously affect the life of the catalyst. Activated carbon can be used as a pre-purification unit to extend the service life of the battery system.

You will get a quote in 24 hours

You will get a quote in 24 hours

How to Choose Activated Carbon to Remove Siloxane

Bituminous coal vs anthracite activated carbon for siloxane removal

Bituminous coal pelletized activated carbon is known for its high adsorption performance and rich and diverse pore structure. Its combination of micropores and mesopores is particularly suitable for the adsorption of volatile organic compounds (VOCs), including siloxanes. The advantages of bituminous coal pelletized carbon are its high porosity and fast adsorption rate, which is suitable for scenarios where pollutants need to be removed quickly. However, its adsorption effect also depends on the specific bituminous coal type and processing technology.

Anthracite pelletized activated carbon is characterized by high density, high hardness, and usually a more uniform pore structure. Compared with bituminous coal, anthracite pelletized activated carbon has a longer service life, better wear resistance. These characteristics make it more stable in some long-term use or high humidity environments, and it is suitable for applications where the siloxane concentration is not high but needs to be removed for a long time.

Bituminous coal vs anthracite activated carbon which is better for siloxane adsorption?

- For high-concentration and fast-processing scenarios of siloxane, bituminous coal pelletized activated carbon is more suitable because its rapid adsorption ability can remove a large amount of siloxane in a short time.

- For low-concentration, long-term siloxane filtration applications, anthracite pelletized activated carbon may be more advantageous because its stability and anti-wear properties can extend service life and reduce the cost of frequent replacement.

In addition, in actual use, factors such as temperature, humidity and pressure must also be considered, and the final choice must be made based on the application environment. You can contact heycarbons and tell us your needs. The heycarbons team will provide you with professional opinions, suggestions and high-quality products.

You will get a quote in 24 hours

You will get a quote in 24 hours

Custom Heycarb Activated Carbon For Siloxane Removal Solutions

Heycarbons provides a full range of activated solutions at competitive prices.

You will get a quote in 24 hours

Steps to Custom Heycarbons Activated Carbon For Siloxane Removal

Consultation

By understanding your needs and requirements, our salesmen work with you to submit the appropriate activated carbon solution.

Quotation

Heycarbons expert customer service will provide you with a free quote based on your requirements as well as product specifications and quantities.

Production

Heycarbons has sufficient inventory and strong production capacity, and will report production progress to you from time to time.

Shipping

Heycarbons know you need to receive the product as soon as possible, after rigorous quality checks and protective packaging, by fedex shipping.

Are You Looking for Heycarbons Activated Carbon Suppliers For Siloxane?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and Heycarbons respect your privacy.

You will get a quote in 24 hours