Heycarbons Activated Carbon For Air Purification Supplier From China

- Over 20 years of industry experience in coal activated carbon manufacturing.

- The annual output of activated carbon is 18,000 tons.

- 16pcs Production Patents.

- High CTC120%, Clean, Small size error<0.1mm.

You will get a quote in 24 hours

Heycarbons Activated Carbon For Air Purification

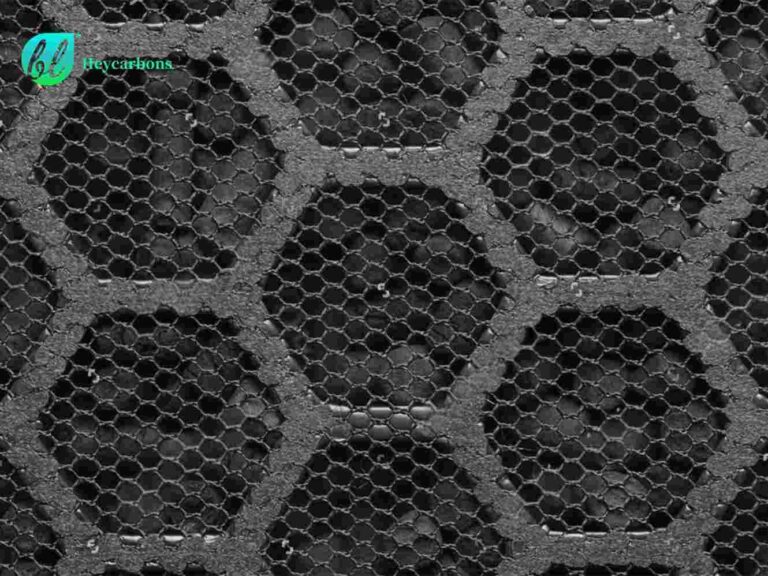

- Gas purification activated carbon typically utilizes coal-based pellet/columnar/extruded/cylindrical activated carbon activated carbon, primarily using Ningxia TaiXi coal as raw material and employing appropriate coal blending techniques. This type of activated carbon possesses characteristics such as high CTC (specific surface area) and ease of regeneration. Heycarbons employ a unique method of carbonization through a patented air-flow high temperature process, which differs from traditional carbon-burning methods. This unique method results in our cylindrical activated carbon having lower ash content and higher strength.

- Coal-based pellet activated carbon Widely used for various exhaust gas treatment, vapor recovery, air treatment, VOCs removal, Biogas H2S removal, Air filter element in air purifier, Solvent recovery, garbage plants, power plants, steel mills, etc. waste disposaletc.

- Coal-based columnar activated carbon main adsorption types: sulfur compounds, nitrogen compounds, hydrocarbons, halogen compounds, carbon-nitrogen compounds, methane and other hydrocarbon gases, CO, arsenic, mercury and other heavy metal-containing waste gases, adsorption of benzene gases, dioxins, odor, etc.

- Of course, some customers also choose to use granular activated carbon, such as 4-8mesh or 5-10mesh, for air purification, as it is more economically beneficial.

- Some customers also use coal-based powdered activated carbon for waste power plants and steel mills flue gas by the injection method.

- Coconut shell granular activated carbon is usually added to cigarette filters to absorb some harmful substances produced by tobacco burning, such as tar, carbon monoxide, heavy metals and nicotine, etc.

Heycarbons Coal/Coconut shell Pelletized Columnar Activated Carbons For Air Purifying

- Size (D :mm): 0.9mm, 1.5mm, 2mm, 3mm, 4mm, 5mm, 6mm, 8mm

- CTC(%): 20, 30, 40, 50, 60, 70, 80, 90,100-120

- Iodine value: Mg/g 500-1100

- Hardness (%): 90-99

- Bulk density: 400-520kgs/m3

- Moisture (%): ≤3

- Ash (%): 8% , 10% , 12% ,14%

- PH: 8-11

Heycarbons Coal/Coconut shell Granular/Powdered Activated Carbons For Air Purifying

- Size: Mesh 4*8, 8*30, 8*16, 12*40, 30*60, 80*150,200,325

- Iodine value: Mg/g 500-1100

- Specific surface area m2/g :500-1150

- Methylene blue: 120-280mg/g

- Molasses value:180-300

- Hardness %:90-99

- Bulk density g/cm3 0.45-0.55

- Ash %: 6-8%, 8-12%, 12-15%,15-18%

- Moisture % : 5 max, 10 max

- PH: 8-11

You will get a quote in 24 hours

Heycarbons Activated Carbons For Air Purification

Heycarbons Pelletized Desulfurization Activated Carbon

1. H2S activated carbon

- Natural gas and Biogas plants generally use pelletized activated carbon or impregnated activated carbon with KOH or NaOH.

- Depending on the use environment, such as when the H2S content is low, the humidity is high, and there is oxygen involved, they also use catalytic activated carbon pellets (CUO, MGO impregnated activated carbon).

2. Extruded activated carbonor impregnated activated carbonwith KOH also be used for control of sewage treatment facility odours(odors) desulfurization and landfill waste gas treatment Desulfurization.

3. Coal Impregnated columnarNaOH/ Koh activated carbon or CuO/ZnOcatalytic activated carbon is usually used for Cabin air purification: SO2 from Fuel cell applications.

Or use coconut shell Impregnated granular activated carbon with NaOH/ KOH or CuO/ZnO for Cabin air purification: SO2 from Fuel cell applications.

Where to buy activated charcoal for odor removal?

You will get a quote in 24 hours

Heycarbons Activated Carbons For Industrial Waste Gas

- For waste incineration power plants, usually use coal-based powdered activated carbon pac:

- Mesh: 200, iodine value: 600-900mg/g, moisture:<5%, and ash < 15%.

2. The main applications of coal-based powdered activated carbon in waste incineration power plants include:

- Flue Gas Desulfurization:

Through adsorption, coal-based powdered activated carbon can effectively remove sulfur dioxide (SO₂) from flue gas, thereby reducing acid rain formation and environmental pollution.

- Flue Gas Denitrification:

Activated carbon can adsorb and catalytically decompose nitrogen oxides (NOₓ) in flue gas, reducing their emissions. Using Selective Catalytic Reduction (SCR) or Selective Non-Catalytic Reduction (SNCR) technology, NOₓ can be reduced to harmless nitrogen (N₂).

- Heavy Metal Removal:

Coal-based powdered activated carbon, with its well-developed porous structure and large surface area, can effectively adsorb heavy metals in flue gas, such as mercury (Hg), lead (Pb), and cadmium (Cd), thereby lowering their emission concentrations.

- Dioxin and Furan Removal:

During waste incineration, toxic dioxins and furans may be produced. Activated carbon can significantly reduce the concentrations of these toxic substances through physical and chemical adsorption, mitigating their environmental and health impacts.

- Volatile Organic Compounds (VOCs) Removal:

Volatile organic compounds (VOCs) generated during waste incineration can be adsorbed by activated carbon, reducing their emissions and preventing air pollution.

You will get a quote in 24 hours

Sulfur Impregnated Mercury Removal Activated Carbon

1. Sulfur Impregnated Mercury Removal Activated Carbon usually uses 4mm coal pelletized activated carbon: CTC: 50-80%, impregnated sulfur: 10-20% . The pH value decreases from the original 9-11 to 1-4.

2. Sulfur impregnated activated carbon is mainly used in the following areas:

- Mercury Removal in Flue Gas :

Industrial boilers, coal-fired power plants, Non-Ferrous Metal Smelting Flue Gas, use sulfur impregnated activated carbon to efficiently adsorb gaseous elemental mercury (Hg0) from flue gas.

Sulfur impregnated activated carbon is used to capture mercury in the flue gas of non-ferrous metal smelting processes.

- Mercury Removal in Cement Production Flue Gas:

The raw materials and fuels used in cement production may contain trace amounts of mercury. Sulfur impregnated activated carbon can effectively capture mercury from the kiln exhaust gas.

- The advantages of sulfur impregnated activated carbon include high adsorption capacity, strong selectivity, good oxidation resistance, and regenerability, making it widely used for removing gaseous elemental mercury from flue gas in the above industrial processes.

You will get a quote in 24 hours

Heycarbons Activated Carbons For Air Filter

- Activated carbon used in gas purification filters mainly uses 4mm columnar activated carbon CTC20-80%.

- Mainly for Activated Carbon Air Filter, Active Carbon Filter For Recirculating Extractor Hoods, HEPA and Carbon Filter, Industrial Carbon Filter, Air Purifier Carbon Filter, Industrial kitchen odor filters.

- Activated carbon filters are widely used in air purification and exhaust gas treatment in household, commercial, automotive and industrial fields.

You will get a quote in 24 hours

Heycarbons Activated Carbon Solvent Recovery

- Solvent Recovery System are widely used in industrial production, such as in the fields of tape factory, rubber, plastics, textiles, printing, paint, and military industries. Organic solvents are primarily used to dissolve certain substances during product manufacturing, but they need to be removed after the product is formed, resulting in a large amount of VOC. Uncontrolled emissions of organic waste gas VOC not only increase production costs but also pollute the environment and cause accidents. Therefore, VOCs Recovery can ensure safe production, purify the environment, and reduce production costs, making it an important part of chemical production.

- Usually use 4mm Coal/Coconut shell Extruded Activated Carbon with CTC 60-90% and iodine value of 900-1050 mg/g

- The main application industries of activated carbon in solvent recovery include:

- Printing industry: used to recover organic solvents such as acetone, methanol and ethyl acetate for dissolving ink, cleaning printing equipment and printing plates.

- Rubber industry: used to recover solvents such as gasoline, benzene and toluene, which are widely used in the rubber production process.

- Chemical industry: including petrochemical industry, synthetic resin industry, etc., recovering various organic solvents such as benzene, dichloromethane, ether, etc.

- Automobile painting: organic solvents such as acetone, methanol and xylene used in the painting process need to be recovered.

- Electronic manufacturing industry: recovery of organic solvents such as acetone, methanol and ethyl acetate used in cleaning and production processes.

- Artificial leather and artificial fiber production: recovery of solvents such as alcohols, ketones, hexane and toluene used in the production process.

- Dry cleaning industry: recovery of solvents used in dry cleaning processes such as tetrachloroethylene.

Activated carbon solvent recovery technology is suitable for recovering solvents from gas with solvent vapor concentrations of 1-20 g/cm³, with a recovery efficiency greater than 90%. The concentration of solvent vapor mixed with air can be kept below the lower explosive limit, making production relatively safe. The cost of solvent recovery using activated carbon is low, the process is simple, and it has a wide range of applications.

You will get a quote in 24 hours

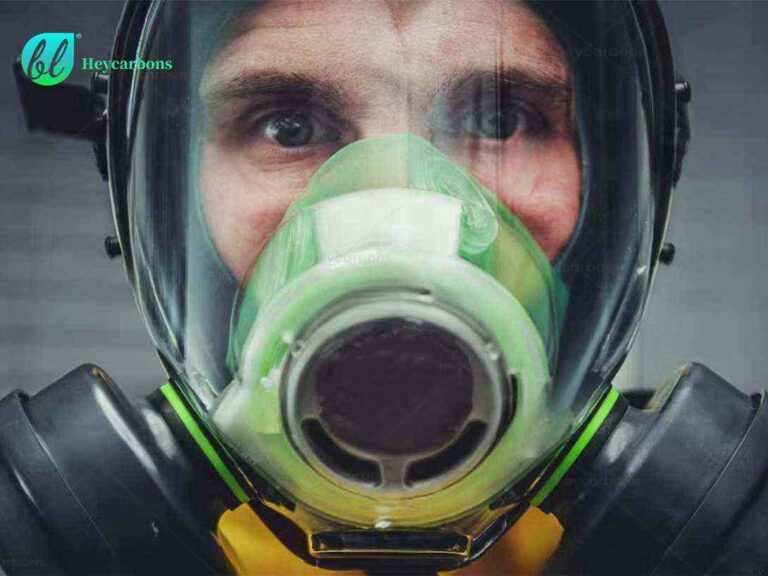

Heycarbons Activated Carbons For Gas Mask

1.Generally, 0.9mm, 1.5mm, 2mm, 3mm columnar activated carbon, CTC70-120% or coconut shell granular activated carbon with a specific surface area 1000-1200 m2/g is made of impregnated activated carbon for gas mask.

2. Gas masks impregnated with activated carbon are mainly used to protect against a variety of toxic gases. Depending on the impregnation material, impregnated activated carbon can effectively adsorb and neutralize specific toxic gases.

3. The following are some common impregnated activated carbons and the gases they protect against:

- General activated carbon: used to adsorb organic solvent vapors in factories.

- Alkali impregnated activated carbon: used to protect against acidic gases.

- Copper salt impregnated activated carbon: used to protect against hydrocyanic acid.

- Potassium bicarbonate impregnated activated carbon: used to protect against sulfur dioxide.

- Zinc salt impregnated activated carbon: used to protect against ammonia and hydrogen sulfide.

- Iodine-containing impregnated activated carbon: used to protect against mercury vapor.

- Compound impregnated activated carbon: For example, the impregnated activated carbon for protection against hydrogen chloride and hydrocyanic acid is a mixture of potassium dichromate solution, silver nitrate solution and basic copper carbonate plus ammonium carbonate and ammonia solution, which is then immersed in activated carbon and then dried and heated.

- Military gas masks also require the addition of metal oxides such as copper Cu, chromium Cr, and silver Ag etc.

In addition, the gas filter canister for protection against carbon monoxide requires the use of activated carbon mixed with a catalyst and a desiccant, usually with copper oxide and manganese dioxide as catalysts, so that the toxic carbon monoxide is catalyzed into non-toxic carbon dioxide.

You will get a quote in 24 hours

Heycarbons Activated Carbons For Cigarette Filter

The application of activated carbon in cigarette filters generally uses 30*60 mesh coconut shell granular activated carbon or 0.9mm coal columnar activated carbon.added to cigarette filters to absorb some harmful substances produced by tobacco burning, such as tar, carbon monoxide, heavy metals and nicotine, VOCs, etc.

The following are some specific applications and effects of activated carbon in cigarette filters:

- Carbon-based compounds: These include formaldehyde and acrolein, which are known carcinogens or mutagens.

- Free radicals: Activated carbon filters can significantly reduce gas phase free radicals, which are highly active oxidants in smoke and are harmful to the human body.

- Volatile organic compounds (VOCs): Such as benzene, toluene and ethyl acetate. These compounds are released during smoking and are harmful to health.

- Heavy metals: Such as mercury, lead, etc. These heavy metals are present in smoke and are toxic to the human body.

- Hydrogen cyanide: a highly toxic gas, activated carbon filters can effectively absorb and reduce its content.

- Ammonia: An irritating gas, activated carbon filters can reduce its concentration.

- Carbon monoxide: Although activated carbon has limited adsorption effect on carbon monoxide, it can still reduce its content to a certain extent.

You will get a quote in 24 hours

Custom Heycarbons Activated Carbon For Air Purification

Heycarbons provides a full range of activated solutions at competitive prices.

You will get a quote in 24 hours

Custom Heycarbons activated carbon for air purification

Heycarbons has proudly served the activated carbon industry with high-quality products since 2005, we can customize your coal activated carbon for your project.

- Cost-effective solutions customized according to customer applications. such as impregnated Alkaline or acidic substances, or impregnated KOH, NAOH, K2CO3, KI, CuO, MgO, KMnO4 etc.

- Customize or mixed different raw materials according to different applications. also customized size, CTC, iodine value, ash, etc.

- Heycarbons customized package to promote your brand, and free design service.

Call Us

+86-180 3788 5195

Our Email

info@heycarbons.com

Heycarbons Coal Activated Carbon

Water Filter

Provide 8*16, 8*30, 12*40, 30*60, 50-150 mesh high iodine value low ash granular carbon for water treatment and water filter – CTO, UDF

Waste water Treatment

Supply of granular and powdered activated carbon for wastewater treatment to remove COD. BOD, heavy metals, organics, acid odors, hydrocarbons, color, etc.

VOCs Removel

Our activated carbon can help remove volatile organic compounds (VOCs) from the air by removing contaminants and impurities.

Gold Recovery

Provides high iodine 6-12, 5-10, 8-16mesh coconut shell granular carbon for gold mining. (CIP, CIL, CIC,)

Air Purification

Heycarbons provide 4mm, 0.9-8mm pelleted and impregnated pellet activated carbon, and granular carbon for various exhaust gas treatment, vapor recovery, and VOCs removal. biogas H2S removal, Cigarette filter, etc.

Solvent Recovery

Provide EAC carbon for high-end air purification or various gas solvent recovery, such as benzene toluene, Dichloro methane solvent recovery, tape factory solvent recovery, and others.

Catalyst Carrier

Special process adding Special substance Pellet (Extruded) activated carbon also named Catalyst activated carbons. used for acid gas treatment such as H2S, water washing regeneration, and high strength.

Food Decolorization

Provide 8*16, 8*30, 12*40 mesh bituminous or briquetting activated carbon for food and water decolorization and purification, such as Sugar, MSG, Juice and wine, Edible oil, glycerin, Sewage decolorization, Corn starch sugar, amino acid, etc.

Steps to Custom Heycarbons Activated Carbon For Air Purification

Consultation

By understanding your needs and requirements, our salesmen work with you to submit the appropriate activated carbon solution.

Quotation

Heycarbons expert customer service will provide you with a free quote based on your requirements as well as product specifications and quantities.

Production

Heycarbons has sufficient inventory and strong production capacity, and will report production progress to you from time to time.

Shipping

Heycarbons know you need to receive the product as soon as possible, after rigorous quality checks and protective packaging, by fedex shipping.

Heycarbons Activated Carbon For Air Purification FAQs

Heycarbons provides on demand activated carbon solutions worldwide, product quality and customer service are highly rated by our partners and customers.

- Testing of selected raw materials

- Comprehensive display and monitoring of production temperature and time

- Sampling inspection of finished products

- Support any form of third-party testing , such as SGS

1. T/T Deposiit + Balance against copy of B/L

2. L/C

3. T/T deposit + L/C for balance

1. If necessary, the technician can go to the site to guide .

2. Order goods are consistent with the sample and TDS

3. Any quality problems occur, the seller will provide solutions within 24 hours.

4. If the package is damaged due to the seller’s negligence, resulting in a shortage of goods,

the seller should make compensation based on mutual agreement.

For customers’ trial orders, we actually do not have a specific MOQ, any amount is acceptable.

Heycarb need to choose a cost-effective transportation method and quantity based on your specific situation.

Normally , 5-7days , also depend on quantity

Yes, Heycarb provide samples for free.

Normally 25kgs/bag , 20kgs/bag , 500kgs/bag , black bag

Support any OEM drawing design bag .

Are You Looking for Heycarbons Activated Carbon For Air Purification Manufacturers?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and Heycarbons respect your privacy.

You will get a quote in 24 hours