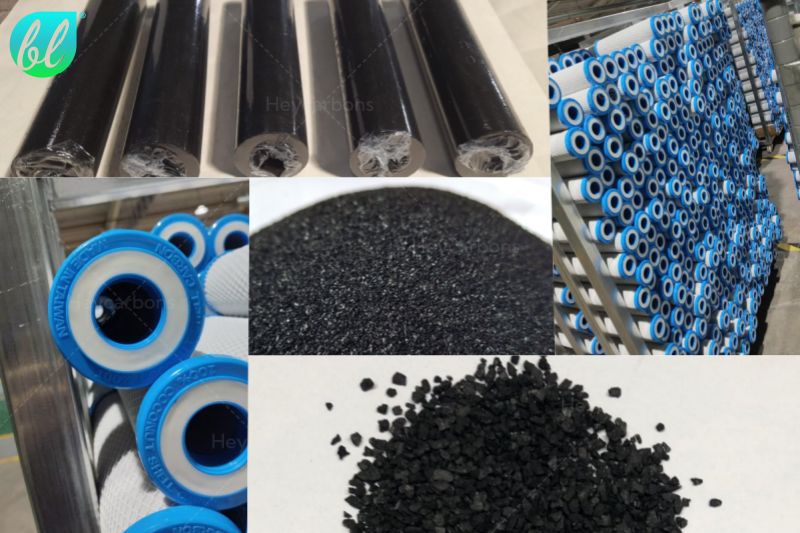

Activated Carbon for UDF CTO Filter Element in Water Purification Heycarbons Manufacturer From China

Activated carbon UDF CTO Filter Element can be used for water purification. You will learn about UDF VS CTO filter elements introduction, water purification process, CTO filter element production process, Heycarbons product introduction and customer cases.

You will get a quote in 24 hours

UDF Filter VS CTO Filter Elements Introduction-What is the difference between UDF and CTO?

UDF filter cartridge (Universal/Upflow Depth Filtration)

What is UDF in water filter? It is filled with granular activated carbon GAC, and sometimes mineralized balls or other functional particles are added.

The water flows through the granular activated carbon for contact adsorption. It has fast filtration speed, large flow rate and large adsorption area.

GAC can initially adsorb residual chlorine, odor and organic matter in the water, and can also intercept some larger particle impurities.

CTO filter cartridge (Chlorine Taste Odor)

What is CTO water filter? CTO is a mixture of activated carbon granules and inorganic liquid binder under high pressure, which is sintered under high pressure to form a dense block structure (also called carbon rod filter element). It has high density and high filtration accuracy (generally around 5 microns). It has high strength and is not easy to break.

It can further finely filter small particle impurities and trace organic matter, while improving the taste of water.

You will get a quote in 24 hours

You will get a quote in 24 hours

Activated Carbon For Water Purification Process-What does filter element do?

Activated carbon has a highly porous structure and a large specific surface area, which enables it to effectively adsorb organic pollutants in water, remove odors, improve taste, and remove residual chlorine and heavy metal ions in water. Coconut shell or coal-based activated carbon is the best choice for treating drinking water.

In modern water purifiers, water is filtered and purified at multiple stages to ensure the safety and purity of the final drinking water.

PP cotton filter element

The whole process usually starts with the PP cotton filter element. As the first line of defense, the PP cotton effectively removes the silt, rust, large suspended particles and some colloids in the water through physical interception, protecting the subsequent filter element from contamination.

UDF granular activated carbon filter element

Then, the water flows into the second stage – UDF granular activated carbon filter element. This stage mainly relies on highly adsorbent granular activated carbon to adsorb residual chlorine, odor and some organic matter in the water, initially improve the water quality and further remove harmful components.

CTO filter cartridge

After preliminary purification, the water continues to flow through the third-stage CTO compressed activated carbon filter element. Compared with granular carbon, the CTO filter element has a denser structure, which can not only deeply adsorb residual chlorine and tiny organic pollutants, but also effectively intercept smaller impurity particles, further improving the purity of the water quality.

RO reverse osmosis membrane or ultrafiltration membrane

If the equipment is equipped with an RO reverse osmosis membrane, the water will pass through this high-precision filter membrane in the fourth stage. RO membrane can completely remove dissolved solids, heavy metal ions, bacteria, viruses and other harmful trace substances in water, achieving a purification effect close to the level of pure water. RO reverse osmosis membrane is relatively expensive, and it is recommended that households use ordinary ultrafiltration membranes.

Post-activated carbon filter element

Finally, the purified water enters the fifth stage – the post-activated carbon filter. This stage is mainly to improve the taste again, remove the trace odor that may be generated during the water storage process, and make the final water taste sweeter and more delicious.

You will get a quote in 24 hours

You will get a quote in 24 hours

UDF Filter Element Production Process-Granular Activated Carbon 8*30

UDF (Uniform Density Filter) filter element mainly uses granular activated carbon (GAC) as the core filter material, and its production process is as follows:

1. Raw material preparation

- Select high-quality coconut shell or coal-based granular activated carbon;

- Matching food-grade PP plastic filter housing, upper and lower covers, sponge sheets or non-woven filter sheets.

2. Filter element assembly

- Assemble and fix the filter mesh and filter housing;

- Use equipment to evenly fill the granular activated carbon into the filter element housing to ensure that the carbon layer is dense but not over-compacted.

3. Sealing treatment

- Encapsulate the upper and lower end covers, using hot melt or mechanical sealing methods;

- Ensure that the seal is leak-free and the structure is firm.

4. Quality inspection

- Check whether the appearance and weight of the filter element are qualified;

- Iodine value detection, flow test, sealing test, etc. can be performed.

5. Packaging and shipment

- Qualified filter elements are shipped after labeling, bagging, and boxing.

You will get a quote in 24 hours

You will get a quote in 24 hours

CTO Filter Element Production Process-Granular Activated Carbon 30*60

The video below shows the actual production of CTO filter elements in the factory:

The production process of CTO cartridge mainly includes several key steps, such as raw material preparation, batching and mixing, extrusion molding, cooling and shaping:

1. Preparation of raw materials-What is inside CTO filter?

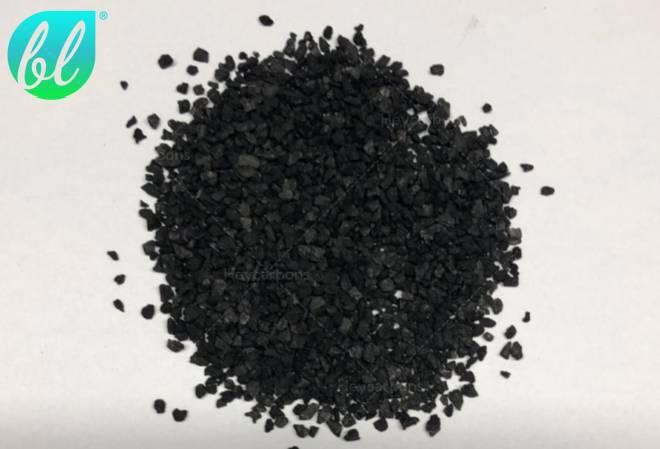

- Activated Carbon Powder: Usually coconut shell activated carbon or coal activated carbon is used, which has high adsorption capacity.

- Binder: such as polyethylene (PE), EVA, etc., which is used to bond the activated carbon powder into shape.

- Other excipients: may include antimicrobial agents, stabilizers, etc.

2. Dosing and mixing

Mix the activated carbon powder with the binder in proportion to the binder and mix well, usually using a high speed mixer for this process. This step ensures that the binder is evenly distributed in the carbon powder for subsequent extrusion molding.

3. Extrusion molding

The mixed material is fed into the extruder, heated to a certain temperature (usually 130℃~180℃) to soften the binder, then extruded through the die to form a cylindrical cartridge and cut into specified lengths.

4. Cooling

The freshly extruded cartridge needs to be cooled by air or water cooling, so as to make its surface and interior curing and molding.

5. Surface trimming and end-face treatment

- The surface of the cartridge is trimmed to make it smooth and regular.

- Add two end caps (usually made of rubber or plastic) and seal them.

6. Drying (optional)

Some manufacturers will dry the cartridge at low temperature to further remove moisture and stabilize the structure.

7. Inspection

- Appearance inspection: no cracks, air holes, qualified size.

- Performance test: such as flow test, residual chlorine removal rate, pressure drop test, etc.

8. Packaging and Storage

Qualified products are packed, labeled, and stored and shipped according to batch.

You will get a quote in 24 hours

You will get a quote in 24 hours

Heycarbons UDF CTO Filter Elements Products Introduction

Heycarbons filter element is used to remove residual chlorine with an efficiency of over 90%. The following is an introduction to heycarbons’ UDF and CTO products.

UDF filter cartridge

The activated carbon used in UDF filter elements is mostly coconut granular activated carbon with mesh sizes of 8*30 and 12*40, and coal-based activated carbon is occasionally used.

You will get a quote in 24 hours

CTO carbon rod filter cartridge

- Coconut shell/coal activated carbon

- Mesh: 30-60, 60-120, 80-200

- Iodine Value: min 1000mg/g

- Ash: max 1.5%

- Moisture: max 5%

Heycarbons UDF CTO filter element applications

- Home water purifier

- Community direct drinking water station

If you want to know UDF CTO filter element price, please click the link below to contact Heycarbons.

You will get a quote in 24 hours

You will get a quote in 24 hours

Filter Elements Customer Case

Power Plant Customer Case

The boiler cooling water in a power plant has a lot of residual chlorine due to the addition of disinfectants or other chemical treatments upstream. In the treatment of boiler cooling water in power plants, large T CTO carbon rods are used for pre-filtration, and small T UDF carbon rods are used for post-filtration to ensure that the residual chlorine is completely removed and the water quality is stable. The activated carbon used can be coconut shell or nutshell activated carbon.

In this case, the specifications of activated carbon used in the filter element are:

- CTO carbon rod 30-60, 60-120, 80-150 mesh

- UDF: CoConut shell granular activated carbon COCO GAC, 8*16, 8*30, 6*12 mesh

Water Purification Customer Case

A customer requested to use carbonized material (Datong coal) as filter element, with no requirements on ash content and strength. The main requirement was an iron content of 3000PPM, or 150-3000PPM after pickling. Generally, customers use carbonized material in pre-treatment or preliminary treatment, and use high-end products for deep filtration in the post-treatment.

You will get a quote in 24 hours

You will get a quote in 24 hours

Heycarbons Activated Carbon Products For Water Treatment

Heycarbons Coconut shell Granular Activated Carbons for drinking water, household water purifier filter (CTO,UDF, RO), community water supply purification, public direct drinking water equipment.

Heycarbons Coconut shell Granular Activated Carbons for drinking water, household water purifier filter (CTO,UDF, RO), community water supply purification, public direct drinking water equipment.

Heycarbons Coal Granular Activated Carbons for tap water, water filter(CTO,UDF) groundwater, rainwater, snow water, river water treatment, RO Water treatment.

Heycarbons Coal Briquetting Granular Activated Carbons for tap water, groundwater, rainwater, snow water, river water treatment, RO Water treatment.

Custom Heycarbons Activated Carbon Solution For UDF CTO Filter Elements

Heycarbons provides a full range of activated solutions at competitive prices.

You will get a quote in 24 hours

Custom Heycarbons Activated Carbon For Water treatment

Heycarbons has proudly served the activated carbon industry with high-quality products since 2005, we can customize your coal activated carbon for your project.

- Personalized service and advice based on your needs and preferences. Different raw materials for different applications.

- Customized size, iodine value , methylene blue, PH, ash, etc. Also acid washing.

- Heycarbons customized package to promote your brand, and free design service.

Call Us

+86-180 3788 5195

Our Email

info@heycarbons.com

Steps to Custom Heycarbons Activated Carbon Water Purification

Consultation

By understanding your needs and requirements, our salesmen work with you to submit the appropriate activated carbon solution.

Quotation

Heycarbons expert customer service will provide you with a free quote based on your requirements as well as product specifications and quantities.

Production

Heycarbons has sufficient inventory and strong production capacity, and will report production progress to you from time to time.

Shipping

Heycarb know you need to receive the product as soon as possible, after rigorous quality checks and protective packaging, by fedex shipping.

Are You Looking for Heycarbons Activated Carbon Manufacturers?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and Heycarbons respect your privacy.