Mercury Catalyst Activated Carbon

Mercury catalytic activated carbon is a kind of activated carbon impregnated with a certain amount of HgCl2 mercuric chloride, which can be used as a catalyst in the production of polyvinyl chloride (PVC) synthesis process.

What is Mercury Catalyst Activated Carbon?

Mercury catalyst is a catalyst, which is a catalytic substance that can speed up chemical reactions, control the direction of reactions and the composition of products without affecting chemical equilibrium.

Mercury-catalyzed activated carbon is activated carbon loaded with a certain amount of mercuric chloride HgCl2, and it looks no different from activated carbon. Usually, coal-based granular activated carbon and coconut shell granular activated carbon are used as base carbon. The impregnation amount of mercuric chloride is usually 4.5%-5.5% or 10.5%-11.5%, which can be adjusted according to customer needs.

Mercury-catalyzed activated carbon is mainly used for catalyst loading in the polyvinyl chloride synthesis process in the petrochemical industry.

Mercury Catalyst Activated Carbon Main Uses

- Used in the synthesis of PVC raw materials to reduce production costs and environmental pollution for companies producing PVC raw materials.

- Accelerate the production of PVC and resin.

What is PVC?

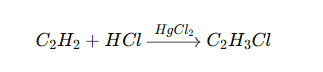

Polyvinyl chloride (PVC) is the largest general-purpose synthetic resin material in China. It has excellent heat resistance, wear resistance, chemical corrosion resistance and other characteristics. It is widely used in industry, construction, agriculture and other industries. Mercury chloride catalytic activated carbon (commonly known as mercury catalytic activated carbon) acts as a catalyst for the synthesis of vinyl chloride (VCM) from acetylene (C2H2) and hydrogen chloride gas in the production of PVC by calcium carbide method.

The Core Function of Activated Carbon as a Carrier

(1) Improving the dispersibility of mercuric chloride

- Physical structure advantages: Coconut shell activated carbon has a high specific surface area (usually ≥1000 m²/g) and a developed micropore/mesoporous structure, which can provide a large number of anchoring points for mercuric chloride and avoid agglomeration of catalyst particles.

- Specific surface area: The pore structure of activated carbon allows HgCl₂ to be dispersed in a monolayer or nanoparticles, increasing the effective active sites.

- Pore distribution: Mesopores (2~50 nm) are conducive to the diffusion of reactants (acetylene, HCl), while micropores (<2 nm) fix HgCl₂.

- Chemical modification to enhance dispersion: The oxygen-containing functional groups on the surface of activated carbon (such as carboxyl and phenolic hydroxyl groups) can bind to Hg²⁺ through electrostatic interaction or coordination bonds, further improving the uniformity of dispersion.

(2) Enhanced reaction efficiency

- Mass transfer optimization: The porous structure of activated carbon shortens the contact path between reactants (acetylene, HCl) and the active sites of the catalyst, accelerating the reaction rate.

- Electronic effect: The π electron system on the surface of activated carbon may participate in the electronic regulation of HgCl₂ and promote the addition reaction of acetylene and HCl (generating vinyl chloride monomer, VCM).

(3) Stabilizing the catalyst

- Reducing the sublimation of HgCl₂: At the temperature of acetylene hydrochlorination reaction (150~180°C), HgCl₂ is easy to sublimate and lose. The adsorption effect of activated carbon can physically bind HgCl₂ and reduce volatilization loss.

- Anti-poisoning protection: Activated carbon can adsorb impurities (such as sulfide and water) in the reaction and protect the active center of HgCl₂.

Mercury Catalyst Activated Carbon Preparation Process

Activated carbon preparation

Select high-strength, large-specific-surface-area activated carbon to remove impurities and ash. The activated carbon is repeatedly boiled and washed in a solution of high-purity hydrochloric acid desalted water, then dehydrated and dried to give it a larger porosity.

Pickling-Acid Washing

Pickle acid washing the activated carbon to remove metal molecules (such as iron molecules: mercuric chloride HgCl2 can react with any metal, so the iron content is also important).

During the pickling process, the metal molecules are converted into chlorides to avoid mercuric chloride reduction reactions. (Attention: The purity and moisture of mercuric chloride HgCl2 also affect the quality)

Impregnation

After acid washing, pH adjustment, heating and adding mercuric chloride, solid mercury agent (90-100℃) impregnation three times, drying, packaging inner film bag tie

*Three layers, AC in the middle layer, water circulation three times, mercury impregnation uniformly

*One cycle, 28 hours in winter, 20 hours in summer: pretreatment 12 hours, impregnation 12 hours, drying

Package

After the mercury content of the activated carbon meets the standard, it is screened and packaged.

You will get a quote in 24 hours

You will get a quote in 24 hours

Heycarbons Mercury Catalyst Activated Carbon Uses

Acetylene (C2H2) chlorination reaction (PVC production):

Mercury catalyst activated carbon formula: Acetylene and hydrogen chloride are catalyzed by mercuric chloride to produce vinyl chloride.

- This reaction produces vinyl chloride (VCM), which is the main raw material of PVC (polyvinyl chloride) plastic.

Application areas:

- Plastic industry: production of PVC pipes, films, cables, packaging materials, etc.

- Construction industry: used to manufacture corrosion-resistant pipes, door and window frames, etc.

Function:

- Increase acetylene conversion rate and make the reaction more efficient.

- Applicable to gas phase reaction process, reduce by-products and improve the purity of vinyl chloride.

Methyl Chloride Synthesis

Mercury-catalyzed activated carbon can be used for the chlorination of ethanol or methanol to produce chloromethane and its derivatives, such as

- Methyl chloride (CH₃Cl): can be used to produce silicone, medicine, dyes, etc.

- Dichloromethane (CH₂Cl₂), chloroform (CHCl₃), carbon tetrachloride (CCl₄): as solvents or chemical raw materials.

Other organic chlorination reactions

Mercury-catalyzed activated carbon can be used in other chlorination processes, such as:

- Benzene chlorination reaction: preparation of chlorinated aromatics (such as chlorobenzene C₆H₅Cl).

- Alcohol chlorination reaction: used to produce chlorohydrin compounds.

You will get a quote in 24 hours

You will get a quote in 24 hours

Heycarbons Mercury Catalyst Activated Carbon Product

Heycarbons Mercury Catalyst Activated Carbon

Mercury catalyst activated carbon uses coal pelletized activated carbon as a carrier, mercuric chloride as the main active component, adds anti-toxic and mercury-fixing additives, and is produced by liquid membrane impregnation and low-temperature and low-humidity drying process. Its performance is greatly improved compared with the old mercury catalyst.

Coconut shell granular Activated carbon for high-mercury chloride catalyst carrier is refined by physical activation method. It is black granular, non-toxic and tasteless, with well-developed pores and reasonable distribution of three types of pores. It is widely used in catalyst carriers in synthetic industries, phosgene synthesis, high-mercury chloride catalyst carriers, chlorine-containing catalysts for rare metal purification, synthetic vinyl acetate and other polymerization, oxidation, halogenation reaction catalyst carriers, etc.

How is mercury used as a catalyst?

Heycarbons Mercury Catalyst Activated Carbon is used as a catalyst in the synthesis process of polyvinyl chloride production by the acetylene method. Its usage is generally: the synthesis reaction temperature is controlled at 100-180℃, the flow rate is controlled at 50-100M³/h, the molecular ratio of acetylene (C2H2) to hydrogen chloride (HCl) is controlled at 1:1.05-1.10; the purity of acetylene (C2H2) is ≥98.5%; the purity of hydrogen chloride (HCl) is ≥93%. In addition, it can also be determined by the user according to his own process rules and procedures.

You will get a quote in 24 hours

You will get a quote in 24 hours

Heycarbons COCO Mercury Catalyst Activated Carbon

Heycarbons’ advantages of COCO Mercury Catalyst Activated Carbon

The raw materials are coconut shells grown from coconut trees that have been growing for more than 5 years. in order to achieve outstanding hardness and attrition resistance.

For coconut shell activated carbon particles, the grinding and air separation process designed for gold refining can just provide better activated carbon support for mercury catalyst services.

1. Grinding reduces edges and corners, reduces debris, makes particles more uniform, and is less likely to cause gas deviation.

2. 6 large dust collectors ensure less floating dust and cleaner

3. Air separation: reduces flakes, increases strength, reduces debris, and makes airflow smoother.

Our grinding, air separation, and dust removal technology exceed 99% of activated carbon manufacturers in China

Please check the video to view quality control production process of coconut shell granular activated carbon :

The following table introduces the specifications of mercury catalytic activated carbon and the parameters of the base carbon used, that is, coconut shell activated carbon.

Mercury Catalytic Activated Carbon Specification

| Project | Specification | |

|---|---|---|

| Appearance | Black flake particles | |

| Carrier | Coconut shell activated carbon | |

| HgCl2, % | High mercury content | 10.5-11.5 |

| Low mercury content | 4.5-5.5 | |

| Moisture, w% | ≤0.3 | |

| Packing density, g/l | 450-550 | |

| Mechanical strength, % | ≥98 | |

| Breakage rate during processing, w% | ≤2 | |

| Particle size distribution | >5mm | <5 |

| 2.5-5mm | >92 | |

| <2.5mm | <3 | |

Base Carbon-Coconut Shell Activated Carbon Specification

| Project | Specification | |

|---|---|---|

| Moisture, w% | ≤8 | |

| Strength, w% | ≥98 | |

| Surface density, g/l | 450-550 | |

| Water capacity, w% | ≥66 | |

| Iodine adsorption rate, mg/g | ≥1100 | |

| Ash, w% | ≤3 | |

| Thickness, mm | ≥2 | |

| Particle size distribution, w% | >5mm | <5 |

| 2.5-5mm | >92 | |

| <2.5mm | <3 | |

| Flake-free (flakes are removed by air separation) | ||

You will get a quote in 24 hours

You will get a quote in 24 hours

Heycarbons Coal Mercury Catalyst Activated Carbon Specification

In addition to coconut shell mercury catalyzed activated carbon, heycarbons also produces coal-based mercury catalyzed activated carbon. You can learn about its specifications from the table below. Of course, Heycarbons can also customize mercury catalyst activated carbon according to your needs

| Project | High Mercury Catalyst | Environmentally friendly low mercury catalyst |

|---|---|---|

| Appearance | Black pellet | Black pellet |

| HgCl2 content (wt) | 10.5%-12.5% | 4.0%-6.5% |

| Moisture (wt) | ≤0.3 | ≤0.3 |

| Packing density | 590-650g/L | ≤580g/L |

| Mechanical strength | ≥98% | ≥95% |

| Particle size | 2.5-4.0mm (Customizable) | 2.5-4.0mm (Customizable) |

You will get a quote in 24 hours

You will get a quote in 24 hours

Custom Heycarbons Activated Carbon Solution

Heycarbons provides a full range of activated solutions at competitive prices.

You will get a quote in 24 hours

What Clients Say on Our Activated Carbon

Custom Heycarbons Activated Carbon

Heycarbons has proudly served the activated carbon industry with high-quality products since 2005, Heycarbons can customize your coal activated carbon for your project.

- Customize different raw materials according to different applications.

- Cost-effective solutions customized according to customer applications. such as impregnated Alkaline or acidic substances, with CuO, MgO , KI

- Customized size, CTC, iodine value, ash, H2S working capacity, etc.

Call Us

+86-180 3788 5195

Our Email

info@heycarbons.com

Steps to Custom Heycarbons Activated Carbon

Consultation

By understanding your needs and requirements, our salesmen work with you to submit the appropriate activated carbon solution.

Quotation

Heycarbons expert customer service will provide you with a free quote based on your requirements as well as product specifications and quantities.

Production

Heycarbons has sufficient inventory and strong production capacity, and will report production progress to you from time to time.

Shipping

Heycarbons know you need to receive the product as soon as possible, after rigorous quality checks and protective packaging, by fedex shipping.

Are You Looking for Activated Carbon Manufacturers?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.

You will get a quote in 24 hours