Reagglomerated Activated Carbon VS GAC Granular Activated Carbon

What is Agglomerated Activated Carbon?

What is an agglomerated material? Different from granular activated carbon, reagglomerated activated carbon uses clean coal from different regions as raw materials to make a proportion, and reagglomerates the powdered coal into particles.

The produced briquette activated carbon has a reasonable pore structure distribution, well-developed micro- and mesopores, high mechanical strength, and is renewable. It has the characteristics of low ash, high iodine value, high molasses value, high methylene blue and no floating matter.

Heycarbons could select clean coal from different provinces and make proportions to produce different types of products according to different application requirements.

You will get a quote in 24 hours

You will get a quote in 24 hours

Reagglomerated Activated Carbon VS GAC Production Process

Agglomerated Activated Carbon

Heycarbons selects different types of clean coal from different regions for making a proportion. The powdered coal is pressed into blocks by machine. After carbonization and activation, the activated carbon is crushed and screened into suitable particle sizes according to customer needs. The video below details the production process of heycarbons reagglomerated activated carbon.

You will get a quote in 24 hours

GAC Granular Activated Carbon

The larger coal particles are processed in the carbonization furnace and then activated. During the activation process, technicians control the different heights and sections of the activation furnace at different temperatures. The activated carbon is cooled naturally in the storage bin. Finally, it is crushed, screened and packaged. The video below details the production process of heycarbons granular activated carbon.

You will get a quote in 24 hours

Comparison

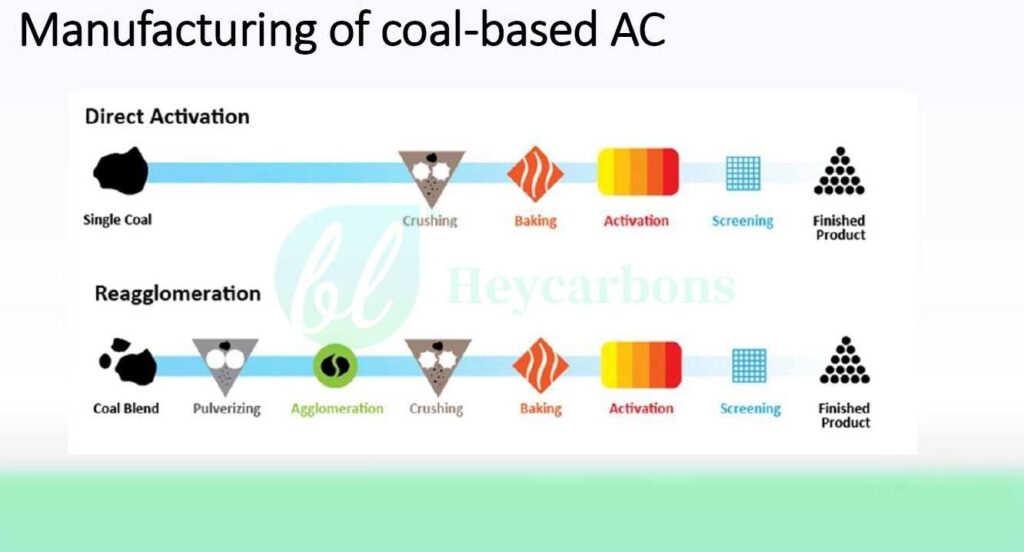

The biggest difference between reagglomerated activated carbon and granular activated carbon is that reagglomerated activated carbon is made by reagglomerated coal powder into blocks, while GAC is made by breaking large blocks into small pieces.

Direct Activation of granular activated carbon production process : the single coal is turned into granular activated carbon after crushing, baking, activation and screening.

Reagglomeration of briquette activated carbon production process : the coal blend is turned into reagglomerated activated carbon after pulverizing, agglomeration, crushing, baking, activation and screening.

You will get a quote in 24 hours

You will get a quote in 24 hours

Reagglomerated Activated Carbon VS GAC Physical Properties

The video shows in detail the difference between reagglomerated activated carbon and granular activated carbon.

Brightness

Due to the different production methods, GAC granular activated carbon is brighter than heavy agglomerated activated carbon.

Granularity

Reagglomerated activated carbon: Due to its unique agglomeration structure, the particle size is more uniform, usually has better mechanical strength and fluidity, and is suitable for the adsorption of high-flow gas and liquid.

Granular activated carbon: The particle size is larger, suitable for adsorption applications that require a larger surface area. Irregular shape, the stacking effect during filling may lead to low porosity, affecting the fluidity of the fluid.

Specific Surface Area

Reagglomerated activated carbon: Compared to granular activated carbon, agglomerated activated carbon has fewer micropores and more mesopores or macropores, which gives it a lower specific surface area. It is usually between 400 m²/g and 800 m²/g.

Granular activated carbon has a relatively large particle size, but due to their complex internal structure, there are a large number of micropores and mesopores, resulting in a large specific surface area. The specific surface area of granular activated carbon is usually between 500 m²/g and 1200 m²/g, depending on the raw materials, activation method and customer requirements. The high specific surface area provides good adsorption performance and high activated carbon adsorber ability.

Mechanical Strength

Reagglomerated activated carbon is made by agglomerating smaller activated carbon particles with a binder. This agglomerated structure gives it a higher overall mechanical strength. The agglomerated activated carbon particles are stronger and less likely to break. The bonding force between particles is stronger, reducing the risk of pulverization. The new extrusion process launched by heycarbons in 2019 ensures excellent mechanical strength and guarantees negligible losses after multiple reactivations.

Granular activated carbon is usually composed of porous carbon particles with a large number of micropores and mesopores on its surface. Although these pore structures provide good adsorption performance, the mechanical strength of granular activated carbon is weak. In high-velocity airflow or liquid, granular activated carbon is easily worn, resulting in breakage and pulverization. This will lead to a decrease in adsorption effect during application, and even require frequent replacement of activated carbon.

Adjustment of Parameters

Reagglomerated activated carbon has more advantages in parameter adjustment. Due to coal blending technology, reagglomerated activated carbon can adjust parameters more flexibly. And it can achieve high methylene blue and molasses value.

You will get a quote in 24 hours

You will get a quote in 24 hours

Heycarb Reagglomerated Activated Carbon VS GAC Products Introduction

Heycarbons HEYRGAC Reagglomerated Activated Carbon

Heycarbons HEYRGAC is a granular activated carbon with low acid soluble iron content, designed for the purification and decolorization of aqueous and organic liquids. It can be effectively used in fixed or moving beds. The particle size selected is 12 x 40 mesh, which allows high adsorption rates and low flow resistance, suitable for liquids of medium viscosity.

HEYRGAC contains virtually no fines or dust. HEYRGAC is made from selected grades of bituminous coal combined with a suitable binder, which gives it excellent hardness and long life. Produced by high temperature steam activation under strictly controlled conditions, this carbon has a high surface area, large pore volume, high density and pore structure, making it ideal for the adsorption of color bodies and odor molecules from solution.

| Specifications | HEYRGAC-02 |

|---|---|

| Iodine Number | 900-1100mg/g |

| Molasses Number | 190-240 |

| Moisture by Weight | max 3% |

| Abrasion Number | min 78 |

| Methylene blue | 150-270 |

| Acid Soluble Iron by weight | max 0.01% |

HEYGAC Reagglomerated Activated Carbon Features

- Metallurgical grade bituminous coal

- Reagglomerated with binders and steam activated

- Acid washed

- Granular product

HEYGAC Reagglomerated Activated Carbon Benefits

- Produces a strongly adsorbing pore structure optimal for the adsorption of color bodies and odor molecules.

- Reduces iron and ash levels so that product does not leach in acidic solutions.

- Cleaner, more efhcient operation than with powdered carbons.

- Lowers product cost, improves product quality.

- Requires less equipment to operate than with powdered carbon.

You will get a quote in 24 hours

Heycarbons Granular Activated Carbon

The HEYGAC coal series is a granular activated carbon produced through steam activation of carefully selected grades of bituminous coal. Its well-balanced combination of adsorption and transport pores ensures optimal performance across a wide range of water treatment, Food decolorization applications.

This product boasts high density as an adsorbent, delivering maximum volume activity. It undergoes a water-washing process during manufacturing, which allows it to wet rapidly. Its exceptional hardness and mechanical strength guarantee minimal losses during backwashing, air scouring, and multiple reactivations.

| Specification | Project | Unit | Parameter | |||

|---|---|---|---|---|---|---|

| HEYGAC coal series | Iodine Value | mg/g | 700 | 800 | 900 | 1000 |

| Moisture | % | max 5% | ||||

| ASH | % | 5% & 8% & 10% & 12% & 15% | ||||

| Hardness | % | 98 | 98 | 97 | 97 | |

| Sizing | mesh | 4×10 & 8×16 & 8×30 10×20 & 12×40 & 20×40 & 30×60 & 80×150 | ||||

| Standaed Packaging | kgs/bag | 25kgs/bag or 500kgs/bag | ||||

HEYGAC Granular Activated Carbon Features and Benefits

- Mesopore development

- Versatile adsorbent

- High mechanical stength

- Good adsorption capacity

- Potable water grade

You will get a quote in 24 hours

You will get a quote in 24 hours

Heycarb Custom Granular Activated Carbon Solution

Heycarbons provides a full range of activated solutions at competitive prices.

You will get a quote in 24 hours

What Clients Say on Our Activated Carbon

Heycarb Custom Granular Activated Carbon

Heycarbons has proudly served the activated carbon industry with high-quality products since 2005, Heycarb can customize your granular activated carbon for your project.

- Customize different materials according to different applications

- Customized size, iodine value , methylene blue, molasses value, PH, ash, etc.

- Cost-effective solutions customized according to customer applications.

Call Us

+86-180 3788 5195

Our Email

info@heycarbons.com

Heycarb Other Activated Carbon Solutions

Water treatment

Heycarb provide 8*16, 8*30, 12*40, 30*60, 50-150 mesh high iodine value low ash granular carbon for water treatment.

Waste water Treatment

Heycarb supply of granular and powdered activated carbon for wastewater treatment to remove COD. BOD, heavy metals, organics, acid odors, hydrocarbons, color, etc.

VOCs Removel

Heycarb activated carbon can help remove volatile organic compounds (VOCs) from the air by removing contaminants and impurities.

Gold Recovery

Heycarb provides high iodine 6-12, 5-10, 8-16mesh coconut shell granular carbon for gold mining. (CIP, CIL, CIC)

Air Purification

Heycarb provide 4mm, 0.9-8mm pelleted and impregnated pellet activated carbon, and granular carbon for various exhaust gas treatment, vapor recovery, and VOCs removal. biogas H2S removal etc.

Solvent Recovery

Heycarb provide EAC carbon for high-end air purification or various gas solvent recovery, such as benzene toluene. Dichloro methane solvent recovery, tape factory solvent recovery, and others.

Catalyst Carrier

Special process adding Special substance Pellet (Extruded) activated carbon also named Catalyst activated carbons. Heycarb used for acid gas treatment such as H2S, water washing regeneration, and high strength.

Food Decolorization

Heycarb provide 8*16, 8*30, 12*40 mesh bituminous or briquetting activated carbon for food and water decolorization and purification, such as Sugar, MSG, Juice and wine, Edible oil, glycerin, Sewage decolorization, Corn starch sugar, amino acid, etc.

Steps to Custom Heycarb Granular Activated Carbon

Consultation

By understanding your needs and requirements, our salesmen work with you to submit the appropriate activated carbon solution.

Quotation

Heycarbons expert customer service will provide you with a free quote based on your requirements as well as product specifications and quantities.

Production

Heycarbons has sufficient inventory and strong production capacity, and will report production progress to you from time to time.

Shipping

Heycarb know you need to receive the product as soon as possible, after rigorous quality checks and protective packaging, by fedex shipping.

Heycarb Granular Activated Carbon FAQs

Heycarb provides on demand activated carbon solutions worldwide, product quality and customer service are highly rated by our partners and customers.

- Testing of selected raw materials

- Comprehensive display and monitoring of production temperature and time

- Sampling inspection of finished products

- Support any form of third-party testing , such as SGS

1. T/T Deposiit + Balance against copy of B/L

2. L/C

3. T/T deposit + L/C for balance

1. If necessary, the technician can go to the site to guide .

2. Order goods are consistent with the sample and TDS

3. Any quality problems occur, the seller will provide solutions within 24 hours.

4. If the package is damaged due to the seller’s negligence, resulting in a shortage of goods,

the seller should make compensation based on mutual agreement.

For customers’ trial orders, we actually do not have a specific MOQ, any amount is acceptable.

We have to choose a cost-effective transportation method and quantity based on your specific situation.

Normally , 5-7days , also depend on quantity

Yes, we provide samples for free.

Normally 25kgs/bag , 20kgs/bag , 500kgs/bag , black bag

Support any OEM drawing design bag .

Are You Looking for Heycarb Granular Activated Carbon Manufacturers?

Contact Heycarb for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and Heycarb respect your privacy.

You will get a quote in 24 hours