Sulfur Impregnated Activated Carbon for Mercury Removal

You will get a quote in 24 hours

What is Sulfur Impregnated Activated Carbon for Mercury Removal?

Mercury is toxic. In industrial production such as coal-fired power generation and metal smelting, if the exhaust gas contains mercury vapor, it will cause great harm to the health of workers and nearby residents.

For the human body, mercury vapor may cause kidney damage, nervous system disorders, cardiovascular disease, etc. The main impact on the environment is pollution of water and soil, causing ecological imbalance.

In order to protect the environment and human health and recover valuable mercury, Heycarbons has developed sulfur impregnated activated carbon for mercury removal.

Sulfur-loaded activated carbon for mercury removal uses high-quality columnar activated carbon as the base carbon and is made through a special process. After being used in the mercury removal device, the mercury removal efficiency and various indicators have reached the domestic leading and world advanced level, filling the domestic gap.

Sulfur Impregnated Activated Carbon Production Process

When producing sulfur impregnated activated carbon for mercury removal, sulfur is fumigated into the activated carbon at high temperature in the vulcanizing furnace. Most of the sulfur is transported into the pores of the activated carbon.

There are three types of activated carbon pore sizes: micropores less than 2nm, mesopores less than 50nm, and macropores greater than 50nm. According to the experimental results of heycarbons, microporous and mesoporous activated carbons are used as raw materials to produce sulfur-loaded activated carbon for mercury removal.

Because most of the sulfur is covered in the micropores and mesopores of activated carbon when the activated carbon carries sulfur, when the gas flows through the sulfur-impregnated activated carbon, mercury vapor is easier and more effective to contact with sulfur.

It reacts quickly with sulfur to form mercuric sulfide, which is deposited in the activated carbon pores to achieve the purpose of mercury removal. The general mercury removal efficiency exceeds 99%.

Parameters of Sulfur Impregnated Activated Carbon for Mercury Removal

Project Index

Raw material pelletized activated carbon

Diameter 4mm

CTC 60, 70, 80, 90(before impregnated)

Sulfur content 8-15, 10-16, 12-20, customize

The concrete values of mercury capacity and CTC of heycarbons sulfur impregnated activated carbon for mercury removal are related to the production process and sulfur content. Please contact Heycarb team, Heycarb could customize suitable sulfur impregnated activated carbon for mercury removal with corresponding mercury capacity and CTC according to your needs.

You will get a quote in 24 hours

Factors Affecting the Quality of Sulfur-impregnated Activated Carbon for Mercury Removal

- Time: The filtration air velocity cannot be too fast and should be controlled at 5-12m/min.

- Sulfur loading: There are three types of sulfur loading: 13% 15-16% 18-19%. The more the better.

- Temperature: The temperature cannot be too high, 10-80℃ is appropriate.

- Bed height: If the tank is relatively high, it is necessary to load the sulfur-impregnated activated carbon for mercury removal in several layers. Generally, the height of each layer is 1.5-2m.

- Bed area ratio: It cannot be laid too thick, otherwise it will affect the air velocity, and should be less than 1.2m.

- Filling volume: If the air intake is large, the working time is long, the tank is large, and the sulfur-loaded mercury-removing activated carbon is small, it will definitely affect the effect.

- Pressure: The pressure should be controlled to be less than 8Mpa.

You will get a quote in 24 hours

You will get a quote in 24 hours

Sulfur-loaded Activated Carbon for Mercury Removal Working Principle

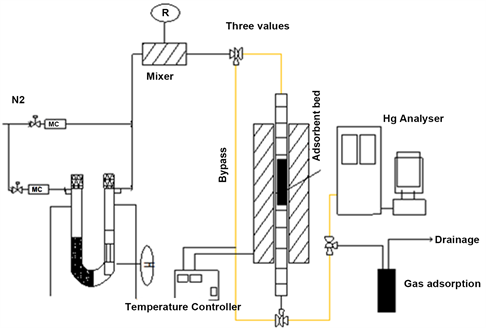

Based on the unique physical and chemical properties of activated carbon, it has become a recognized effective technology for mercury removal.

Activated carbon has a highly developed pore structure, a large specific surface area, and a strong adsorption capacity. The gaseous mercury molecules are firmly adsorbed, which can effectively reduce the mercury content in the flue gas.

However, mercury molecules may be released at high temperatures or under certain conditions, so it is often necessary to further fix the mercury through chemical reactions.

Specially treated sulfur-impregnated activated carbon for mercury removal can convert mercury molecules in flue gas through chemical reactions to generate stable mercury compounds. The picture on the right introduces the adsorption process of sulfur-impregnated activated carbon.

Chemical Reaction of Mercury Removal by Activated Carbon

1. Sulfurization reaction of mercury (forming mercury sulfide)

Sulfur-impregnated activated carbon for mercury removal contains sulfur sources (such as calcium sulfide, ammonium sulfide and sodium sulfide).

These sulfides can react with mercury to form mercury sulfide (HgS), which is very stable in the environment, has low volatility and is not easily released back into the atmosphere.

Chemical reaction formula: Hggas+S→HgS

2. Chlorination reaction of mercury (forming mercury chloride)

If the surface of sulfur-impregnated activated carbon contains chloride (such as calcium chloride or sodium chloride), the mercury in the flue gas reacts with the chloride to form mercury chloride (HgCl₂). This makes the mercury no longer exist in gaseous form, but becomes a stable mercury compound.

Chemical reaction formula: Hggas+Cl2→HgCl2

3. Oxidation reaction of mercury (forming mercury oxide)

The oxides on the surface of sulfur-loaded activated carbon for mercury removal react with mercury to form mercury oxides. This process helps to fix mercury molecules and reduce their mobility in the gas.

Chemical reaction formula: Hggas+O2→HgO

4. Synergistic reaction with sulfur dioxide (desulfurization)

In some sulfur-impregnated demercured activated carbons, the sulfur source not only reacts with mercury, but also reacts with sulfur dioxide (SO₂) in flue gas to generate sulfates or sulfites (such as CaSO₄ or CaSO₃), thereby achieving the desulfurization function.

Chemical reaction formula with sulfur dioxide: SO2+Ca(OH)2→CaSO3+H2O SO2+1/2O2+CaO→CaSO4

These reactions help reduce the concentration of sulfur dioxide in flue gas, while also reducing the harm of sulfur dioxide to the environment.

You will get a quote in 24 hours

Application of Sulfur Impregnated Activated Carbon for Mercury Removal

Sulfur-impregnated demercured activated carbon can be used in the following areas:

- Oil extraction

- Metal ore smelting, especially mercury ore smelting

- Natural gas purification

- Coal-fired power generation

Client Case on Activated Carbon for Removal of Mercury

One of heycarb customers uses sulfur-impregnated activated carbon to remove mercury in a methanol plant.

The customer’s requirement is to remove mercury from coke oven gas, so the accuracy of mercury removal is relatively high. The operating conditions of the methanol plant are shown below. Heycarbons can also customize sulfur-loaded activated carbon for mercury removal according to your specific needs.

- Gas volume: 98000Nm³/h (operation flexibility 50-110%)

- Operating temperature: 40℃

- Operating pressure: 2.4MPa

- Components of imported gas (v%):

Gas composition H2 CH4 CO CO2 O2 N2 CnHm H2O Proportion 56.25% 19.56% 16.52% 0 0.08% 5.79% 1.80% saturation - Mercury content in the raw gas inlet of the demercuration tower: ≤10ug/Nm³

- Mercury content after purification: ≤0.01ug/Nm³

- Initial requirements resistance: ≤20Kpa

- Final requirements resistance: ≤40Kpa

- The total sulfur at the outlet is required to be less than the total sulfur at the import. If the total sulfur at the outlet is higher than the total sulfur at the import, the product is considered unqualified.

The pictures taken at the methanol plant are shown below:

Heycarbons activated carbon is a leading supplier in China with 20 years of history, serving all over the world. With a professional sales team, technical support and advanced production equipment, heycarb company can customize activated carbon according to your needs and provide you with better services.

Contact Heycarb to get e-brochure and free samples!

You will get a quote in 24 hours

You will get a quote in 24 hours

Why 100+ Clients Choose Heycarb

01

Competitive Prices

Build factories where raw materials are produced, recycle steam, and save costs. And Heycarb do not differentiate customer groups, unified price system, while ensuring quality, only earn a reasonable profit.

02

Quick Response

Once you leave a message, our team will usually get back to you as soon as possible within 24 hours, even if it's just a short confirmation message.

03

Professional

Our sales and customer service teams are fully trained in products and product applications and have the expertise and problem solving skills.

04

Excellent Quality Assurance

Strict raw material screening system: coal-to-activated carbon raw material testing, only accept low ash and low sulfur high-quality anthracite and bituminous coal raw materials.

05

Fast Delivery

Inventory preparation of regular products facilitates rapid delivery while saving plant capacity in preparation for custom products.

06

Product Testing

A full set of testing equipment and laboratories . Ensure everry batch of multiple mixed testing to ensure quality. It also supports any form of third-party testing for customers.

Heycarb Activated Carbon FAQs

Heycarbons provides on demand activated carbon solutions worldwide, product quality and customer service are highly rated by our partners and customers.

- Certified Activated Carbon Manufacturer

- Testing of selected raw materials

- Comprehensive display and monitoring of production temperature and time

- Sampling inspection of finished products

- Support any form of third-party testing , such as SGS

1. T/T Deposiit + Balance against copy of B/L

2. L/C

3. T/T deposit + L/C for balance

1. If necessary, the technician can go to the site to guide .

2. Order goods are consistent with the sample and TDS

3. Any quality problems occur, the seller will provide solutions within 24 hours.

4. If the package is damaged due to the seller’s negligence, resulting in a shortage of goods,

the seller should make compensation based on mutual agreement.

Normally , 5-7days , also depend on quantity

Yes, we provide samples for free.

Normally 25kgs/bag , 20kgs/bag , 500kgs/bag , black bag

Support any OEM drawing design bag .

What Our Clients Say Us

Are You Looking for Heycarb Activated Carbon Manufacturers?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and Heycarb respect your privacy.

You will get a quote in 24 hours